The Hydroelectric Dam Case Study

Setting the Scene

Nestled in the Southeast US lies a hydroelectric dam. Though its original design was tailored to produce hydropower, today, it also aids in the regulation of water flow and water temperature for other plants downstream. Like all power-producing facilities, maintaining top-tier technology for maximum efficiency is paramount.

The Challenge

The dam faced a lingering issue with outdated switches used to protect their lake water cooling equipment. Imagine switches with dial gauges mounted on walls that plant personnel had to squint at, attempting to discern readings. These antiquated switches weren’t just hard to read; they brought along a myriad of reliability and accuracy concerns. In the modern age, this was far from ideal.

The Solution

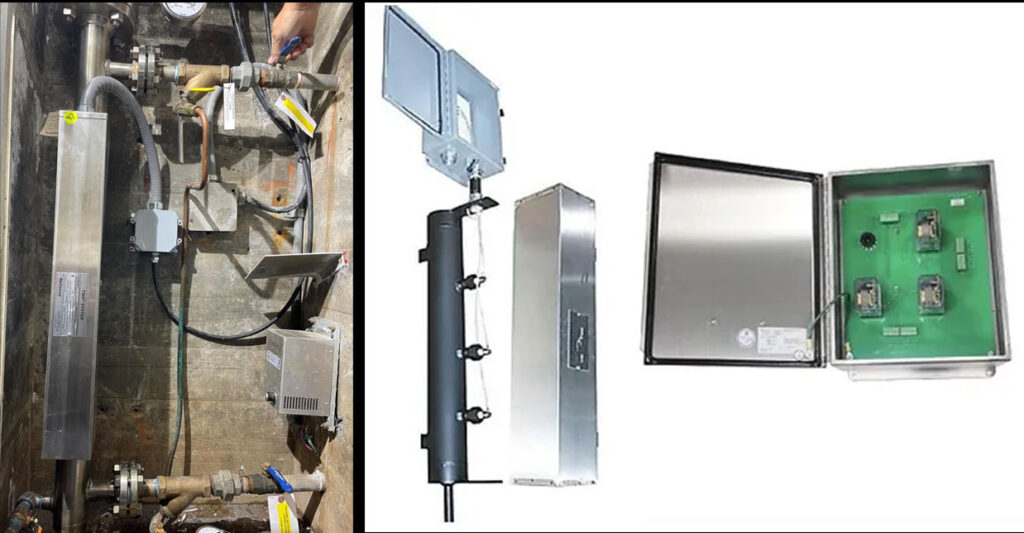

Enter the TWIP® (Turbine Water Induction Protection) Level Switch. A solution tailored to meet the challenges faced by this dam, it offers:

- Advanced Detection: By ruling out false alarms, the TWIP System provides reliable detection. It pairs top-tier sensing Probes with state-of-the-art equipment.

- Customized Implementation: Its design can be modified to fit specific locations within any steam plant.

- Precision with Two-Trip Probes: These can be installed vertically at the same level to ensure consistency, even with voting logic circuitry.

- Voting Logic Advantage: By integrating a circuit logic, any 2 of 3 probes activate the trip circuit upon water detection, virtually eliminating false trips or single level control failures.

The result? The dam now enjoys unparalleled reliability, accuracy, and the benefits of modern technology.

Relevance to the Oil & Gas Industry

While this hydroelectric dam example paints a vivid picture of the TWIP® Level Switch’s capabilities, its applicability stretches far and wide, notably into the Oil & Gas sector.

- Safety & Operational Efficiency: In oil storage and processing tanks, water detection is paramount. Water presence can accelerate corrosion, promote bacterial growth, and even lead to hydrate or ice formation in colder environments. A system like TWIP ensures oil quality and safety by accurately detecting and managing water levels.

- Equipment Protection: Oil & Gas environments, especially offshore rigs, cannot afford equipment failures. Just as it benefited the hydroelectric dam, the voting logic of TWIP offers nearly fail-safe water detection, safeguarding valuable equipment.

- Customizability for Diverse Environments: Whether it’s an offshore oil rig or a desert-based drilling facility, the TWIP® Level Switch’s adaptability ensures it meets the unique demands of each Oil & Gas operation.

Conclusion

Westech Industrial’s Reliance TWIP® Level Switch has showcased its prowess in the hydroelectric realm. Still, its benefits are not confined to one industry. Those in the Oil & Gas sector, take note: this technology is equally poised to revolutionize your operations.

To discover how the TWIP® Level Switch can elevate your facility, whether in hydroelectric power or Oil & Gas, reach out to us. Visit Westech Industrial’s website at https://bit.ly/3YXRvsj or call 1-800-912-9262. Bridging industries with technology, we’re here to serve your unique needs.

Share This:

Next Article