In the critical field of oil and gas, ensuring the safety of operations and personnel is paramount. A major refinery faced a significant challenge in monitoring hazardous H2S and combustible gases around vital areas such as vapor recovery units and knock out drums near emergency flares. The need for a robust, reliable monitoring system was unmistakable, particularly considering the unique challenges presented by the existing infrastructure. In this specific context, the financial and logistical considerations made traditional wired gas detectors less feasible, underscoring the need for a more adaptable solution. This case study explores how the United Electric Controls (UEC) Intrepid WirelessHART® Field Gateway, developed by Centero, provided a groundbreaking solution to these challenges, exemplifying innovation in safety technology.

The Challenge of Monitoring in Expansive and Complex Sites

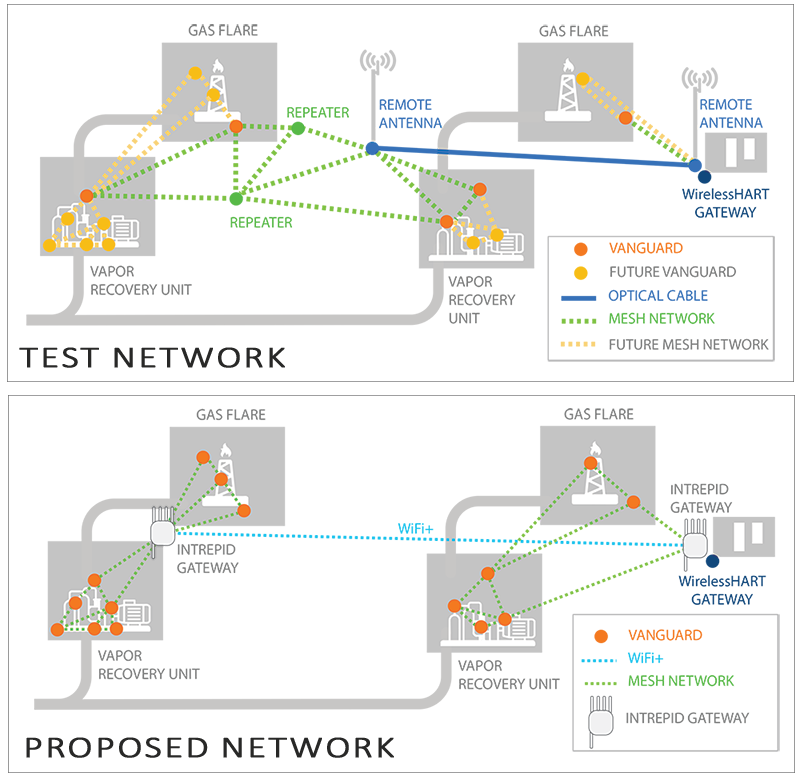

The primary obstacle was the lack of input/output (I/O) support for traditional wired gas detectors, coupled with the large distances and extensive wiring that would be required for effective leak monitoring. Initially, the refinery tested a limited deployment using a traditional gateway and Vanguard WirelessHART gas detectors. However, the layout of the flare sites and the distance from the plant network connection introduced significant data transmission bottlenecks and network latency risks.

To combat these issues, an elaborate setup involving an antenna with a 350-meter cable and two repeaters was implemented. Although this approach somewhat mitigated the risk of data loss and network latency, it introduced additional complexity, cost, and still did not fully eliminate the problem of network “hops.”

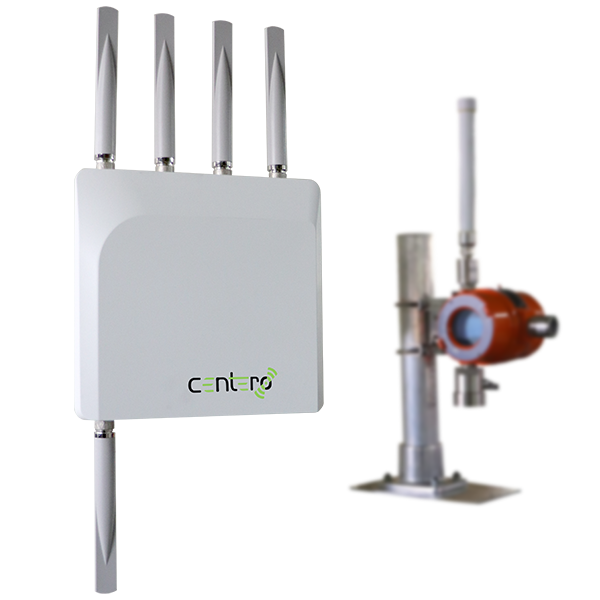

The Solution: UEC Intrepid Gateway by Centero

The breakthrough came with the introduction of UEC’s Intrepid Gateway, which incorporates Industrial WIFI Mesh+ technology alongside WirelessHART. This innovative solution rendered the two repeaters and the extensive cabling unnecessary. By leveraging this advanced gateway, the refinery was able to establish two separate mesh networks around each flare line, significantly reducing latency and eliminating the issue of hops that plagued the initial setup.

Moreover, the Centero gateway opened up new possibilities for integrating additional industrial Wi-Fi devices, such as infrared cameras. This expanded the scope of monitoring and safety measures beyond what was previously possible, enabling the use of more WirelessHART devices around each flare line.

Key Results: A Leap Forward in Industrial Safety and Efficiency

The implementation of the Intrepid Gateway led to robust and simplified infrastructure expansion and a more reliable network design. These improvements not only enhanced safety around critical refinery operations but also demonstrated the potential for significant cost savings and operational efficiencies.

The successful deployment of UEC’s Centero gateway solution illustrates the power of innovative technology to solve complex industrial challenges. By overcoming the limitations of traditional monitoring systems, the Intrepid Gateway has set a new standard for safety and reliability in the oil and gas industry.

Learn More with Westech Industrial and UEC

Westech Industrial is proudly partnered with United Electric Controls (UEC) as the distributor of their INTREPID WirelessHART® Field Gateway and the UEC Vanguard WirelessHART gas detectors. This collaboration highlights our shared commitment to advancing safety in industrial environments. Our offerings, focused on industrial safety, deliver cutting-edge solutions to enhance the protection and efficiency of your operations.

Highlighting Our Safety Solutions:

INTREPID WirelessHART® Field Gateway: Revolutionizing field connectivity, this gateway merges WirelessHART and WiFi MESH+ technologies, providing unmatched ease of deployment, extensive network coverage, and a superior line-of-sight range of up to 1.2 miles (2,000 meters).

UEC Vanguard WirelessHART Gas Detectors: Complementing our safety solutions, the Vanguard gas detectors excel in the flexible, reliable, and secure monitoring of hazardous gases. These devices integrate seamlessly with the INTREPID Field Gateway, elevating safety and operational efficiency to new heights.

Designed for Durability, Ease of Use, and Security:

Tailored for the rugged demands of industrial sites, including hazardous zones, our solutions are not only robust but intuitive and scalable. With advanced security measures like AES-256 encryption, we ensure your critical operations are protected and future-ready.

Driving Safety in Industrial Automation:

Through our partnerships with UEC, Rosemount/NetSafety, Kenexis and Federal Signal Westech Industrial is dedicated to offering top-tier safety solutions that foster efficiency, reliability, and innovation. We’re here to support your journey toward safer industrial automation with the latest technologies, designed with your safety and operational needs in mind.

Embark on a Safer Future with Us:

Discover how the INTREPID WirelessHART® Field Gateway and Vanguard WirelessHART gas detectors can redefine safety in your process automation infrastructure. Reach out to Westech Industrial for guidance on embracing these advanced safety solutions in your operations.

📞 Contact us at 1-800-912-9262 or visit our website at https://westech-ind.com to learn more about our focused approach to industrial safety. Let’s work together to achieve excellence in safety and efficiency with the forefront of automation technology.

Share This:

Next Article