Amid increasing demand for minerals central to the clean energy transition, mining technology companies like Orica have a critical role to play.

Orica has been involved in the Australian mining scene since its earliest days.

Founded in 1874 to supply explosives to the Victorian goldfields, the company has grown to become one of the world’s pre-eminent mining and infrastructure solutions providers.

This year marks 150 years of Orica, and as the company reflects on its proud history, it’s simultaneously compelled to drive the continued evolution of technology and mining smarts.

While deposits are getting deeper and harder to delineate, the demand trajectory for many minerals is surging higher amid an accelerating clean energy transition.

Independent drill and blast solutions are important, but the Australian mining industry is increasingly in need of interconnected, end-to-end solutions that drive improved productivity and safety across a number of operational pillars.

Only then can miners and contractors look to achieve the production targets put to them by boardrooms and greater global demand.

Orica’s 150th anniversary coincides with the 35th anniversary of SHOTPlus, one of the company’s pioneering innovations for blast design and modelling.

“Many of Orica’s significant technological advancements occurred with SHOTPlus,” Orica digital solutions senior manager for technology Matthew Craft told Australian Mining.

“SHOTPlus has led to and underpinned current products like BlastIQ and OREPro 3D. These fundamental products support our core services but also stand alone as independent products themselves.”

While SHOTPlus has proved to be a revolutionary solution in the design and modelling of blasts, BlastIQ enables operators to have full control of their blasting process, delivering quality control management of blast design implementation.

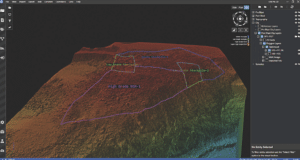

OREPro 3D leverages Orica’s rich background in blast movement and dynamics to provide what is the mining industry’s first solution that optimises grade control in 3D.

According to Orica digital solutions product manager Alfred Tsang, OREPro 3D was developed to meet the mining industry’s demand for a digital solution that ensures safe, precise, cost-efficient and optimised grade control.

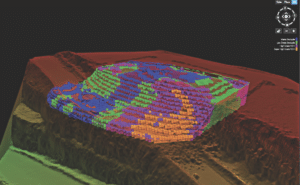

“OREPro 3D enables production geologists to create instructions which help an operation deliver maximum ore value recovery,” Tsang told Australian Mining.

“The technology is not unique to a specific type of deposit. It is used across the industry in multiple commodities, including gold, copper, iron ore, zinc, lithium, nickel and platinum, to name a few.”

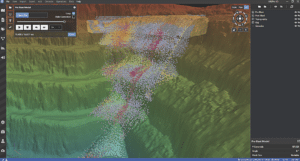

The in-situ definition of the ore resource is disrupted when a blast occurs, which means operators cannot rely on their predetermined assessment of the orebody when recovering the ore and the commodity within that.

OREPro 3D gives operators greater control of the process.

“The OREPro 3D team recognised that there could be a modern blast modelling solution that takes readily available mining data, uses intelligent algorithms to replicate blast movement dynamics, and applies that to the in-situ blast volume so operators have an accurate representation of their post-blast muck pile,” Tsang said.

“Since OREPro 3D Predict was launched in 2021, there have been some incredible advancements around how we model blast movement and how we optimise the delineation of economical ore in the post-blast space.”

Beyond delivering more accurate post-blast ore recoveries, OREPro 3D helps to achieve better safety and efficiency outcomes.

“With OREPro 3D, we eliminate the need for workers to traverse post-blast muck piles,” said Tsang. “It allows operators who would normally conduct in-field measurements to make faster and more accurate assessments from the safety of their office.”

OREPro 3D is automatically calibrated on every blast with the help of topographic surveys, which can be taken by spatial data-capture technologies such as drones, photogrammetry, and light detection and ranging (LiDAR), all of which keep operators out of harm’s way.

Then there’s the efficiency piece.

“Paired with modern computing advancements, the OREPro 3D Predict physics engine is an implementation of Orica’s deep knowledge of blast dynamics,” Tsang said.

“What wasn’t possible a decade ago is now proven.

“In the early 2010s, using the same methodology of blast modelling, where we need to understand material that is broken up into, for example, 10,000 individual rock fragments, this type of processing would take upwards of 24 hours.

“We’re now able to do that same modelling on a blast that’s segmented into hundreds of thousands of fragments in a couple of minutes.

“Because of that drastic improvement in speed, we can afford to have really accurate and granular modelling of that blast movement on a production scale, which is important to be able to describe the change in material position from in-situ to post-blast.”

One of OREPro 3D Predict’s key value propositions is its ability to model blast movement ahead of time.

“Once a certain level of calibration is achieved, the OREPro 3D Predict physics engine enables customers to model the potential blast movement and recoverable value before it happens,” Tsang said.

“This is achieved by pairing our OREPro 3D Predict physics engine with a dig line optimiser – an intelligent algorithm that uses modern computer processing power to design and delineate economical ore in the post-blast space.”

St Barbara’s Touquoy mine in Canada reported the benefits of OREPro 3D as a significant reduction in dilution and ore loss.

Having used OREPro 3D on 33 blasts over 12 months, the mine increased grade by seven per cent and decreased dilution by 6.5 per cent when compared to previous systems. This boosted St Barbara’s revenue by $1 million across the 33 blasts.

These numbers are even more impressive when considering that Touquoy is a mill-limited operation.

Reducing waste by 6.5 per cent through the crusher means St Barbara was able to feed additional material from the stockpile, increasing revenue by another $1.1 million.

The ability to conduct accurate pre-blast and post-blast modelling means operators can approach blasts with a multi-dimensional strategy that enables improved ore value recovery and ensures downstream operations can continue at pace.

“Leveraging the speed of the OREPro physics engine and the speed of the dig line optimiser, OREPro 3D can deliver powerful and sophisticated outputs with simple inputs,” Tsang said.

“Ultimately, OREPro 3D enables production geologists to meet production pressures and ensures they are no longer the bottleneck in the mine-to-mill process.”

OREPro 3D is made even more intuitive by it’s easy-to-understand workflow, which brings greater functionality and predictability to any mine site.

This feature appeared in the July 2024 issue of Australian Mining.