Known globally as a leading supplier of bulk material handling solutions, TAKRAF owes its reputation to its advanced technologies and quality client support.

TAKRAF’s technical expertise, work planning and execution skills help to ensure successful project delivery. But the company is also one of the industry’s largest and most competent full-service suppliers of bulk material equipment, boasting significant experience in the maintenance, refurbishment and upgrade of a wide variety of equipment.

As a result, the company is now in demand to support material handling equipment that is no longer being supported by its original equipment manufacturer (OEM).

“In times where many players seem to move away from materials handling projects, we at TAKRAF live for this and, by doing so, we help our customers secure the metal supply of the future in a sustainable way,” TAKRAF Group chief executive officer Thomas Jabs said.

Holistic approach to maintenance

TAKRAF (an acronym for Tagebau-Ausrüstungen, Krane und Förderanlagen) provides customised maintenance solutions for its equipment from the locations in which it operates.

Material handling equipment it supports includes the full range from conveyors and spreaders to all stockyard, loading/un-loading equipment and port machines. Of particular note is the group’s refurbishments and upgrades of equipment such as stackers and reclaimers to extend machine life, upgrade equipment to the latest standards, and increase capacity.

Just as operational efficiency is a focus area in TAKRAF’s maintenance solutions, achieving such efficiency with increased safety is a non-negotiable of the group’s holistic approach to maintenance.

With the philosophy that an improved maintenance solution must always have a safety upside and increased safety does not need to come at the expense of maintenance efficiency, TAKRAF has shown that efficiency and safety do in fact complement one another.

In line with its holistic approach, TAKRAF addresses maintenance requirements and the associated safety risks from the start of the engineering process. For example, numerous accidents and even fatalities can occur while replacing a chute liner. These can be the result of a range of risks, from falling material to the unsafe handling of tools and equipment.

One method to reduce risks is to design chutes with modular sections (or rotable chutes) that not only provide a significant improvement in safety but also reduce downtime from an eight-hour shift to 60 minutes.

However, TAKRAF’s ultimate safety approach in this regard is to make it possible to stay outside of the chute at all times during maintenance with, for example:

- the lip liner being accessible from the outside

- wear plates with external access

- ultrasonic measurement of liner thickness, and therefore wear, from outside the chute to allow for planned maintenance.

Other benefits of this approach include significant savings in downtime as liner exchange can start immediately after the operational stop, since no scaffolding is required.

Conducting maintenance on belt conveyors and the replacement of worn or damaged rolls (idlers), which can run into thousands on long overland conveyors, is challenging. This is especially true on steep slopes, in tunnels or on elevated structures. TAKRAF’s maintenance cart was therefore developed to access any location along a conveyor belt in the shortest possible time and in the safest manner.

At a major copper project in North America, a TAKRAF maintenance cart services a steep 26 per cent decline section of a 4350m overland conveyor. This 1250m section features more than 3700 rolls.

A similar TAKRAF maintenance cart for a large copper mine in South America was of interest to the client due to the increased safety it would provide over its complicated 6000m overland conveyor. Featuring a number of horizontal curves, this conveyor required bridges to be built on more than 50 per cent of its length, making it extremely difficult for maintenance to be conducted.

Advanced, customised technology solutions

Recognised as a leading technology brand in bulk material handling, TAKRAF’s solutions cater to clients’ unique requirements from the supply of individual machines to complete integrated systems.

Recent projects across the globe have continued to demonstrate TAKRAF’s technology prowess. In Australia, for example, the group’s rail-mounted stacker at a bulk terminal is one of the largest ever delivered and, with its unique design features, one of the most technically advanced.

The stacker boasts an initial stacking capacity of 6300 tonnes per hour (tph) and a massive 62m curved boom, but was designed at the outset to accommodate a peak volumetric rate of up to 10,700 square metres per hour (equal to 9600tph) for a scheduled future upgrade.

In the design of the world’s most powerful belt conveyor system for a major copper miner in Chile, the numerous innovations developed during the project resulted in six patents. The application of gearless drives on the two main underground conveyors (totalling more than 6300m) and the overland conveyor (more than 5300m) represented a major step forward, as it significantly reduced the number of main wear parts and reduced the drive system’s footprint and emissions.

The 11,000tph system boasts a total installed drive power of 58MW (58,000kW) – the underground conveyors feature 10,000kW of installed drive power per drive pulley and 20,000kW per conveyor, while the overland conveyor features three 5000kW direct drive motors.

These highly efficient electric drive motors replace diesel truck engines, cutting CO2 emissions produced when transporting the material by more than two thirds for the same copper volume.

“This project highlights TAKRAF’s commitment to more sustainable and environmentally friendly installations,” the company said.

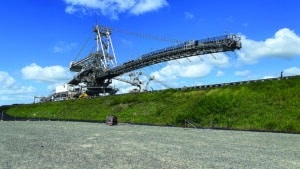

Other recent projects in South America include supply of a 13,200tph belt conveyor system for copper ore and a 7200tph bucket-wheel reclaimer for iron ore.

In North America, TAKRAF replaced a 6000tph rail-mounted stacker for limestone in southern Mexico, designing a robust machine that could operate in the hot, humid and corrosive environment, and in high-velocity winds. This machine was replaced in just three days.

Following the successful delivery of a contract for Phase 1 of a bauxite expansion project in Guinea, Africa, TAKRAF is supplying a further two conveyors to the project. The Phase 1 contract included delivery of a greenfield wagon unloading and primary crushing station, a secondary crushing station and a complex brownfield conveyor system. The structure of the unloading station is constructed entirely from steel, which presented a major engineering challenge, considering the high dynamic loads and forces resulting from the continual passage of trains.

Four portal reclaimers supplied to a new multi-commodity power plant in Japan are some of the largest ever built. Due to the redundancy required – two reclaimers are required to work on the same rail in the same warehouse – a dedicated safety and anti-collision system was implemented.

Each machine has a dedicated platform to carry a small bulldozer, which it can drop off at any location along the stockpile for cleaning purposes.

This feature appeared in the October 2023 issue of Australian Mining.