Conditions in an underground mine can change in a heartbeat. Emesent is keeping miners informed on what they’re walking into.

Change detection and convergence monitoring might sound like a mouthful, but no underground mine can operate without it.

When excavating below the surface, the displacement and movement of rock can have significant consequences, including everything from injuries to unscheduled delays.

Things can change dramatically in an instant, and that’s why efficiently and effectively monitoring change and convergence across the whole excavation process is a vital safeguard.

But as anyone who’s set foot on a mine site can attest, monitoring underground mine conditions is not so simple.

Only a fraction of the subterranean network is observable through drill holes or excavation fronts, meaning critical data is hard to capture and often missed.

Traditional monitoring methods have their place but are often expensive or time-consuming, with some capturing as little as five per cent of the overall rock mass affected by mining.

In short, they just aren’t up to the task.

Enter Emesent, a data capture specialist on a mission to revolutionise the way mine mapping is done.

Emesent co-founder and chief strategy officer Stefan Hrabar said the company’s change detection and convergence monitoring solution is helping operators make more informed decisions.

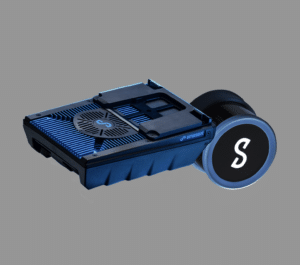

“We combine the output from Emesent’s Hovermap hardware with an automated workflow in our Aura software to create one seamless solution,” Hrabar told Australian Mining.

“The Hovermap uses rapid-capture mobile simultaneous location and mapping (SLAM) technology to capture detailed, accurate data over a wide area. It can sense a range of up to 300m and capture more than a million points of data per second before Aura steps in to take monitoring to the next level.”

Aura’s convergence monitoring workflow allows the comparison of two scans, captured at different times, to identify change.

“The scans can track everything from displacement and damage to rehabilitation efforts,” Hrabar said.

Image: Emesent

While Aura comes bundled with all Hovermaps, the optional convergence monitoring module enables mining professionals to scan excavations throughout their site more regularly and quantitatively monitor change.

These results enable operators to track excavation behaviour and identify areas requiring additional monitoring.

“Although many mines have implemented SLAM technology into their monitoring plans, Emesent is the first to provide a combined data acquisition-to-implementation solution,” Hrabar said.

But Hrabar emphasised observations and monitoring data produced in isolation provides a limited idea of the larger processes at play.

“Rock masses are complex, heterogeneous and non-linear systems with interactions between components,” he said. “Extracting the most from convergence monitoring results involves combining the results with other available geological and geotechnical information.”

While many mines have used SLAM technology to scan the entire site and establish a baseline, Hrabar said the alignment of these scans is a time-consuming manual process that usually requires complex third-party software.

“Uniquely, the solution eliminates the need for data transfer between multiple third-party software for the alignment and visualisation tasks necessary for change detection and convergence monitoring,” he said.

“This collation of insights allows geotechnical engineers to understand where change is happening and more accurately respond to improve workplace safety and mine productivity.

“That context provides the basis for sound engineering decision-making processes.”

Hrabar said the repeatability and efficiencies enabled by the Emesent solution have the potential to transform operational safety across the industry.

“Aura’s results can also be imported into most mining packages used on sites, making this phase of monitoring a seamless process,” he said.

“It ultimately delivers a faster, more efficient workflow and more repeatable, quantifiable outputs on where change or dilation is occurring and the rate of this change over a large area.”

By augmenting Hovermap’s ability to capture detailed 3D data with a convergence monitoring module in Aura, Hrabar said Emesent is making it easier for operators to keep their workers safe while boosting overall efficiency.

“Safety is the top priority when it comes to underground mining,” he said. “Emesent has been working with its customers to help them take the next step in their journey towards safer, more efficient, and more productive mining.”

This feature appeared in the August 2024 issue of Australian Mining.