When a major coal miner sought to ensure the safety and injury-free operation of its draglines, it turned to SICK for an innovative AI-based camera system solution.

Few machines stand out on a mine quite like a dragline excavator.

These heavy-duty machines pick up hundreds of tonnes of ore in every scoop and, at around 70m long, are hard to miss on any mining operation.

But the bigger the machine, the smaller people walking around the machine seem, which can spell trouble for both the employee and the mine.

“A dragline operator essentially works with a bucket from hundreds of metres away in the operating cabin,” SICK product manager Tim Baron told Australian Mining. “To put the scale into perspective, you could drive a heavy truck into those buckets, and the dragline excavator machine housing is many times bigger than the bucket.

“You can imagine if someone is walking behind the cab performing cable relocation work, the risk of being struck by rotating dragline is high; they are unlikely to be detected by the operator.”

And it’s not just the mining and technology companies that are noticing this inherent problem.

“The OH&S (occupational health and safety) body associated with the mining industry has a goal to eliminate injuries and deaths from draglines,” Baron said. “That’s where we come in.”

Baron was recently on-site at a major coal mine to install a SICK Visionary-B Two camera and help the operator monitor blind spots around their dragline base area.

The camera also provides adequate supervision for anyone undertaking work in the vicinity of operational swing boundaries of the dragline.

“The camera is installed under the excavator, identifying people around it and identifying how many metres away they are from the danger zone,” Baron said. “This danger zone can be customised for each machine.”

A live feed from the camera is transmitted to a screen in the operator’s cabin. Not only does the screen show those moving near the excavator, but it will also indicate their distance from the machine.

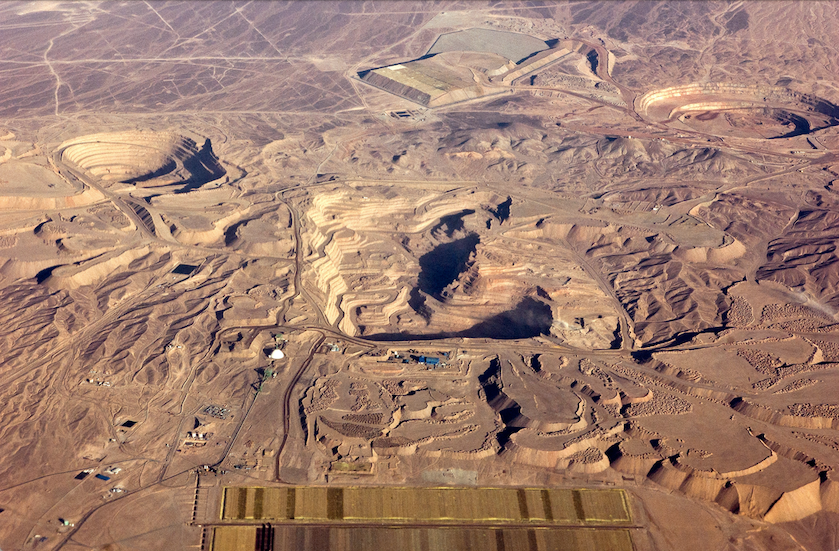

Image: SICK

The number of metres a person is from the machine is shown in a colour scale: red to indicate danger, orange to indicate caution, and green to indicate safety.

By using a camera based on artificial intelligence (AI), there’s no danger of non-human objects being detected.

“We’re working to eliminate false signals altogether,” Baron said. “So when the operator hears the alarm, it’s because there is a real danger of injury.

“Ultimately, this technology will save lives.”

Baron explained how SICK developed the Visionary-B Two camera to work in the often-harsh Australian mining environments.

“Using a security camera won’t suffice because that will easily break,” he said. Our Visionary-B Two camera is built to last.”

Mine sites are often filled with various objects, like light vehicles, that can obstruct an operator’s view of people around a machine.

Luckily, the Visionary-B Two only needs to see a fraction of a person to report their presence to the operator.

“The camera only needs to see 30 per cent of a person and can measure the exact distance of the object from the person with millimeter precision,” Baron said.

“We’ve also tested the camera with a crowd, and it can detect and measure the distance of every person in that crowd.”

Baron said the coal miner was delighted with the camera and its installation.

“This Visionary-B Two camera has been a game changer for the company,” he said. “It excels at detecting people around the machine with its advanced technology all packed into a robust, easy to install unit.

“The camera demonstrates exceptional effectiveness in detecting individuals across diverse conditions, owing to its advanced technology and robust SICK sensor.

“The camera’s very accurate distance detection and user-friendly setup are remarkable – just bolt it on and you’re ready to view.”

This feature appeared in the August 2024 issue of Australian Mining.