ANDRITZ is finding innovative ways to help mining companies be more sustainable in their operations.

As the mining industry explores ways to enable greater operational sustainability, effective tailings management has become a major focal point.

As one of the leading companies in industrial separation technologies, ANDRITZ offers a suite of advanced tailings solutions designed to optimise water recovery, reduce environmental impact, enable dry-stacking solutions, and enhance overall operational efficiency.

ANDRITZ’s tailings offerings encompass a wide range of products designed to cover every aspect of the tailings management process. The company’s solutions extend from sedimentation and dewatering to filtration and water recovery.

“Our broad portfolio for tailings treatment covers the full solid–liquid separation process, including decanter centrifuges, heavy-duty belt presses, hyperbaric and vacuum disc filters, vacuum belt filters, and filter presses,” ANDRITZ regional manager – Australia and New Zealand Paul Stevens said.

Image: ANDRITZ

These solutions aim to maximise water recovery, reduce storage volumes, and provide safer disposal options for processed tailings.

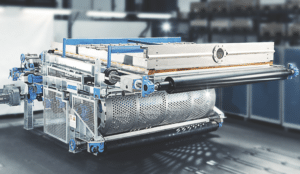

Among ANDRITZ’s many products, the company highlights its heavy-duty belt press CPF-Q and robust filter presses as key solutions for tailings dewatering.

“Our heavy-duty belt press CPF-Q is a reliable and robust machine that is simple and cost-efficient to operate,” Stevens said. “The CPF-Q is a solution for high throughput tailings dewatering, achieving a low residual moisture with low operating costs.”

Additionally, the excellent water recovery rates of ANDRITZ’s filter presses, a technology known for delivering high filtration rates even in harsh conditions, contribute to reducing water consumption and improving sustainability.

The company’s decanter centrifuges also play a crucial role, especially for operations dealing with slurries that have fine particle size distributions. These machines, with high-speed design capabilities and large diameter-to-length ratios, are particularly effective in handling high volumes while enhancing recovery rates.

Innovation is at the core of ANDRITZ’s strategy in tailings management. The company’s research and development (R&D) efforts in the field of tailings management are focused on three primary objectives: enhanced water recovery, sustainability, and automation and digitalisation.

ANDRITZ is actively developing technologies that maximise water extraction from tailings, which is vital for regions where water scarcity is a significant issue. The company is also exploring ways to reuse processed tailings in applications like construction materials, further promoting sustainable mining practices.

Automation and digitalisation are becoming an increasingly important part of ANDRITZ’s solutions.

“We’re working on advanced monitoring systems and AI-supported process controls that can optimise tailings management in real-time,” ANDRITZ industry director – minerals and mining Mario Gerards said. “This digital shift not only enhances operational efficiency but also improves safety and reduces downtime.”

Mining environments are notoriously tough, and equipment longevity is a major concern. ANDRITZ addresses this by utilising high-quality, wear-resistant materials in its designs and offering comprehensive maintenance programs.

“Our solutions are engineered with robust construction to withstand continuous operation in the harshest conditions,” Gerards said.

ANDRITZ’s commitment to providing comprehensive global service support ensures that equipment remains in peak condition, minimising operational disruptions.

And the company’s focus on reducing energy consumption through optimised designs adds another layer of sustainability to its offerings. By delivering a complete range of solutions from dewatering to water treatment, ANDRITZ enables streamlined operations that maximise efficiency across the entire tailings management process.

One of ANDRITZ’s most notable success stories and one of the best references for dry stacking of tailings comes from the Itaminas iron ore mine in Brazil. By implementing ANDRITZ filter presses with LENSER filter plates as well as an advanced Metris addIQ control system, the mine achieved significant improvements in water recovery and reduced tailings volumes.

Image: ANDRITZ

This not only minimised Itaminas’ environmental footprint but also lowered operational costs associated with tailings storage, proving the value of ANDRITZ’s technologies in real-world applications.

Looking ahead, ANDRITZ is working on several cutting-edge technologies aimed at revolutionising tailings management.

“One of our current development programs is focused on significant operational enhancements within our filter press technology,” Gerards said.

“Inspired by our vast experience in the Brazilian iron ore industry, we have implemented R&D in improving filter plate handling and filter cloth changing technology.”

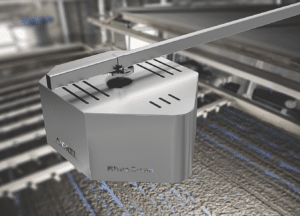

Another interesting innovation is the Metris addIQ RheoScan, a system designed to optimise polymer dosage in real-time during the dewatering process.

“This technology automatically adjusts polymer dosing based on the rheological properties of the tailings, ensuring maximum efficiency in flocculation and sedimentation processes,” Gerards said.

The result is reduced polymer consumption, enhanced water recovery, and lower operational costs.

ANDRITZ is currently developing digital twin models that simulate and optimise tailings processes in real-time. These virtual models allow operators to predict and fine-tune performance, leading to improved efficiency and safety in tailings management.

The company is also exploring energy recovery systems that capture and reuse energy generated during the dewatering process, turning waste into a valuable resource stream.

ANDRITZ also plans to roll out a new filter press design over the next 12 to 18 months, alongside other advancements like enhanced digital twin applications and energy-efficient filtration systems.

These innovations are expected to significantly reduce the environmental footprint of tailings management while improving operational efficiency and safety.

This feature appeared in the October 2024 issue of Australian Mining.