Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

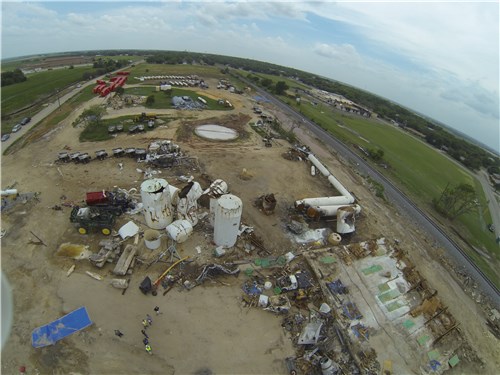

On Nov. 27, 2019, the coastal refinery town of Port Neches, Texas, was rocked by a disaster. At a chemical plant owned by TPC Group, a petroleum product called butadiene accumulated in a dead-end section of pipe, forming popcorn-like clumps of plastic.

The clumps built up so much pressure that the pipe ruptured, spewing butadiene and creating a flammable vapor cloud that ignited. The explosion was felt 30 miles away, injuring 10 people and forcing the evacuation of about 50,000 within a four-mile radius. Fires burned for more than a month at the partially destroyed facility.

The U.S. experiences a chemical disaster on average once every two days, including at least 45 so far in 2024, according to the nonprofit Coalition to Prevent Chemical Disasters. However, a new safety rule the Biden administration recently released is meant to avoid chemical disasters like the TPC Group explosion. EPA officials say the update to the Risk Management Program rule will mandate better disaster preparedness measures and public disclosure of hazardous chemicals at 11,740 facilities nationwide.

If the rule had been in place at the time of the Port Neches explosion in 2019, it “may have mitigated or prevented the accident from occurring,” EPA officials said.

Chemical safety advocates praised the EPA’s new requirements but added that the agency needs to go further, including by adding a notoriously explosive farm fertilizer – ammonium nitrate – to the list of chemicals that should require companies to develop risk management plans. Advocates also say EPA should have included more safety requirements and mandates for air monitoring at the fence lines of major facilities so nearby residents can see what chemicals are being released in real time.

“We’ve needed this rule for a long time,” said Maya Nye, executive director of chemical safety advocacy coalition Coming Clean. But she added that “additional measures are needed.”

The final rule ends a decade-long tug-of-war over regulating the safety of chemical plants. The Obama Administration first proposed a series of safety updates in 2013 after a massive explosion at a fertilizer depot in West, Texas, killed 15 people, injured 260, caused $153 million in offsite damage and leveled large areas of town.

The Trump Administration then halted President Obama’s proposed safety improvements. And then the Biden Administration in 2022 began moving ahead again with the Obama-era rule, adding a few additional requirements.

Ironically, the latest rule still does not address safety issues surrounding the chemical that caused the explosion in West, Texas: ammonium nitrate, which is made from natural gas. EPA has still not added ammonium nitrate to its list of hazardous chemicals that trigger Risk Management Program requirements. About 1,300 facilities across the U.S. store the highly explosive fertilizer, and at least 106 spills or accidental releases of ammonium nitrate chemical have been reported across the U.S. over the last decade, seven of which involved fires, five of which required evacuations, nine of which resulted in 13 injuries, and two of which resulted in deaths, according to a 2023 Environmental Integrity Project report, “The Fertilizer Boom.”

Many advocates continue to urge the EPA to update its list of hazardous chemicals that trigger the rule, including ammonium nitrate. In the final rule, EPA officials called ammonium nitrate “a priority chemical for EPA’s upcoming review,” but not something that was included following the review over the last decade.

The new EPA rule does include several elements designed to better protect public safety. These include a new EPA database that the public can use to look up information about dangerous chemicals stored on-site at local industries. The EPA is also requiring companies to perform studies that could facilitate better planning for natural hazards, including hurricanes and floods made worse by a warming climate. The rule also empowers plant employees to have more say in planning for disasters and shutting down equipment to prevent catastrophic pollution releases.

Here is a closer look at some key provisions in the new rule:

Safer Technologies and Alternatives Analysis

One provision of the new rule is intended to make companies adopt inherently safer processes at their facilities. The EPA is requiring that oil refineries and chemical plants undergo a Safer Technologies and Alternatives Analysis, a formal exercise in comparing safer alternatives and documenting why they choose not to use them.

A subset of these facilities that EPA considers most risky must adopt at least one new safety measure after each of these analyses. This applies to chemical plants or refineries within one mile of another chemical plant or refinery, chemical plants or refineries that have reported at least one accident over the past five years, and refineries that use a dangerous process called hydrofluoric acid alkylation.

The U.S. Chemical Safety Board has identified hydrofluoric acid as “one of the eight most hazardous chemicals regulated by the EPA Risk Management Program.” In 2019, a pipe in the hydrofluoric acid alkylation unit at the Philadelphia Energy Solutions (PES) refinery ruptured, releasing a cloud that ignited, triggering a massive explosion and fire that permanently shut down the refinery.

U.S. Rep Dan Crenshaw (R-TX) introduced a bill last week to try to block the new EPA safety requirements, in part because he objected to the increased scrutiny of hydrofluoric acid. But the Chemical Safety Board’s 2022 report on the PES explosion in Philadelphia makes the potential hazards of hydrofluoric acid clear and concludes that “technologies are being developed that could be a safer alternative” to hydrofluoric acid.

Under the new EPA rules, a requirement for companies to perform a broad Safer Technologies Analysis applies to 621 refineries, chemical plants and other facilities nationwide. Several safety advocates described this as a positive step but said the EPA could have strengthened this provision. “They have to implement at least one minor change that they find,” Nye said. “It could be just the most passive of safeguards, but they do have to implement something, so that is new.”

New EPA database and disclosure requirements

Getting information about which hazardous chemicals are stored at a facility has traditionally been a headache for advocacy groups, journalists, and people living nearby. EPA required that a requestor visit an EPA reading room in person and only take paper notes, with no copies or photos allowed.

When announcing the new rule, the EPA for the first time released a database where anyone can look up a list of chemicals stored at a facility along with a list of past accidents.

However, the EPA’s chemical disaster data are often missing major incidents that made local or even national news. One example: the EPA database has little information on a Denka chemical plant in St. John the Baptist Parish, Louisiana, sued by the federal government over cancer-causing chloroprene emissions. Chloroprene is not one of the chemicals included in the EPA’s Risk Management Program list, so it does not show up in the database.

“We don’t actually come away with much information that we didn’t know before,” said Cynthia Palmer, senior petrochemical analyst at Moms Clean Air Force. “I was expecting to see more information in the database.”

The new rule also allows anyone who lives, works, or spends significant amounts of time within 6 miles of a covered facility to request data directly from the company. The owner or operator must supply the information within 45 days and in two languages used in the nearby community other than English.

Palmer said the radius should be much larger than 6 miles. She added that the 45-day response period is too long and “may very well hinder community efforts to avoid the dangers of chemical facility incidents, as this information is often needed in real time.”

Employee participation

The new rule strengthens the roles of plant workers in helping plan for disasters and stopping work to avoid them. The rule requires companies to allow employees to shut down equipment or refuse to perform a task “when doing so could reasonably result in a catastrophic release.”

The rule also clarifies the right of employees to submit an anonymous report about “an unaddressed hazard, nonreported accident, or noncompliance” and requires the owner or operator to keep a written record of the report. Operators are required to provide training on these procedures.

Natural hazard planning

The EPA updated the rule to require companies to explicitly address natural hazards, including those caused by climate change. It is also requiring companies to evaluate the risk of losing electricity at the site. Facility operators must also within three years ensure that they have standby or backup power available for control equipment and air monitors, which frequently stop recording data during power outages.

Darya Minovi, senior analyst with the Union of Concerned Scientists, described the natural hazards assessment as “really positive,” with about a third of covered facilities at risk of natural disasters.

“The one downside is there were no requirements to actually do anything about the natural hazards assessment,” Minovi said. “I think there was an assumption that facilities will do what they need to do to plan for and prevent a disaster. … We’ve not always seen that to be the case.”

Third party audits

Before the update, the EPA had required facility operators to have a third party, typically a hired consultant, audit the facility’s processes under a specific set of criteria. These criteria included having two accidents over the past five years and the facility being a refinery or chemical plant within a mile of another refinery or chemical plant.

Under the new rule, facilities must undergo a third-party audit if they have had only one accident in the last five years. The EPA is also requiring third-party audits whenever the EPA or a state environmental agency requires it. Operators also must share these audits with their boards of directors.

“The biggest thing that we saw as a positive in the final rule was that they are now requiring those after one incident rather than two,” Minovi said.

The EPA left out one provision that has been a big priority for environmental and chemical safety advocates: fenceline monitoring. Under a separate set of regulations, oil refineries are required to collect data on emissions of benzene, a potent carcinogen, at their fence lines and share that data publicly. Advocates said the EPA ought to require fenceline monitoring data for a much broader set of facilities.

“Such information should be made readily available to the public and to first responders,” said Palmer of Moms Clean Air Force. “Time and again, emergency crew members risk their lives to try and protect communities from chemical disasters without even knowing what they are being exposed to and what precautions to take.

Email from Oil & Gas Watch News, by Brendan Gibbons, bgibbons@environmentalintegrity.org

Lead photo: The explosion and fire that rocked the TPC Group petrochemical plant in Port Neches, Texas, in November 2019. Photo by U.S. Chemical Safety Board.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica TV Video

CleanTechnica uses affiliate links. See our policy here.