Flexco’s XP staple fastener provides a durable and intelligent conveyor splicing solution for underground operations.

There are few places tougher to work than an underground coal mine. Such a rugged environment taxes equipment as much as it does workers, which is why having the right tools for the job is essential.

In response to this demand, Flexco has developed its new XP staple fastening system for conveyor belts, specialised for heavy-duty underground operations.

“Flexco has been making fasteners for over 115 years,” Flexco NSW territory manager Khy McLennan told Australian Mining.

Founded in 1907 in a small workshop in Chicago, Illinois, Flexco invented the first mechanical belt fastener for leather belting. Today, the company holds 70 patents for its mechanical belt fasteners and installation tools.

“The XP system really shines in these underground operations,” McLennan said. “It’s versatile, easy to use and quick to set up. We’re seeing a whole new level of capability in terms of how these underground mining operations manage their belt maintenance schedules.”

The XP fastener is especially sturdy, with a belt strength rating of 1400 kilonewton per metre (kN/m) to 3500kN/m.

But durability is where the XP staple fastener really shines.

“One of the biggest issues for underground conveyors is the longevity of components,” McLennan said.

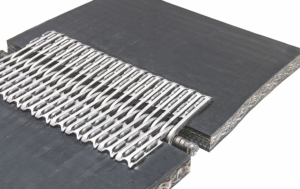

“The XP has a unique ribbed design that protects the staples from premature failure.”

The staples are set in the grooves of the steel fastener plates, creating a low profile that helps shield them from abrasion against the material conveyed, as well as other conveyor components such as rollers and belt cleaners.

“Fastener longevity was at the forefront of the XP design. The finished splice has a smooth, low profile, dramatically increasing the wear life,” McLennan said.

“Our customers are amazed at the longevity of our fasteners compared to others on the market.

“Shutting down a conveyor to repair a damaged clip is extremely disruptive. You’ve got to stop the belt and the longwall operations, so fastener durability is critical.

Flexco said its main goal with the XP was to create something that lasts longer in a harsh environment than anything else on the market.

“We have a trial going on at the moment where a competitor’s staple fastener lasted around three weeks at an underground mine in New South Wales,” McLennan said. “The XP has been running on the same conveyor for 12 weeks – and it’s still going.

“If customers have the potential to keep running a conveyor for another seven or eight weeks-plus without stopping, it helps production rates, reduces maintenance windows and saves them money.

“This also allows them to focus on other, more critical maintenance projects.”

The XP applicator tool sets one fastener at a time, translating to far fewer misdrives and tool jams. Should the occasional misdrive occur, the tool allows the operator to skip over it, continue the splice, and return to drive the staple.

“When it comes to underground mining, you’re not always working in the nicest conditions,” McLennan said. “Dust build-up can often affect machinery. The XP system is designed to handle these harsh conditions.”

All of the applicator tools have a sealed housing that discourages material build-up on internal components, making it easy to maintain.

The XP is ergonomically designed for worker safety. The single-lever pneumatic and hydraulic applicator tools compress the plate before driving and folding the staples in one smooth motion, producing a consistent, quality staple set and finished splice each time.

“A lot of the feedback we’re getting on this fastener is not just about how well it’s performing, but also that the tooling is really easy to use and less taxing on the body,” McLennan said.

“When Flexco designed the XP, we took a lot into consideration to not just provide a better clip, but a better experience on the whole.”

The XP staple fastening system is new ground for the century-old company, whose first ever product was a belt fastener.

Combining a rich history of manufacturing with the latest in technology and market awareness, the XP is Flexco’s solution to underground mining conveyors.

This feature appeared in the September 2023 issue of Australian Mining.