Description of the problem

Work environments where the ambient air is contaminated by high concentrations of dust represent challenges for the operation of machinery, in addition to posing a major risk to the health and safety of workers.

Current filters, although effective when new and clean, are blocked quickly and must be changed regularly, at the risk of causing mechanical breakdown, loss of performance, air pollution and above all a risk to the workers’ health.

The last filtration system you will ever need to install

What is this thing? The only self-cleaning air filtration system.

What does it do? It eliminates the need for air filter replacement.

What are the benefits?

- it prevents engine wear

- it reduces fuel consumption

- it reduces greenhouse gas emissions

- it eliminates filer purchases, storage, management and disposal

- it eliminates downtime caused by filter replacement

- it is equipped with a datalogger for easy troubleshooting and references.

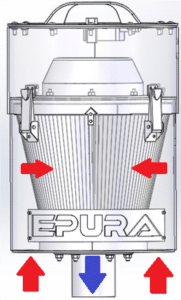

How does it work?

- dirty air gets in at the base of the system

- it then goes through the high efficiency filter

- it comes out 99.73 per cent clean

- the self-cleaning system removes dirt from the filter with low sound frequencies.

Effects on combustion engines

Gasoline and diesel engines must be supplied with a specific amount of clean air. In order to ensure this supply, a filter system is installed at the air intake, making it possible to intercept the particles of ambient dust pulled in.

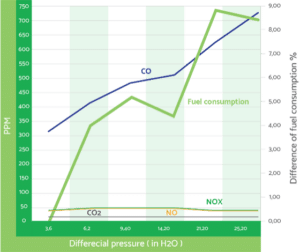

When the filter is saturated, the air flow is reduced, causing the combustion parameters to change. Far from being negligible, this modification causes poor combustion and stress on the mechanical components.

Concretely, a bad air-fuel mixture implies an increase in the generation of carbon that can lodge in the engine components and damage them. In addition, there are problems with engine performance, increased fuel consumption and greater greenhouse gas emissions.

To maintain good combustion in work environments with a high concentration of dust, the filters must be changed regularly, which involves production stoppages, increases the maintenance and operating costs of the machinery, not counting breakage. mechanical and repair costs caused by fouled engines.

Advantages of the Epura system

- reduces the emission of polluting emissions into the air

- reduces the fuel consumption

- protects the engine and its components by eliminating fine particles and ensures optimum performances

- filtered cabin – clean air at all time for the equipment operator

- controllable module – adjustable and constant pressure

- certified ISO 23875 compliant.

Epura engine field testing

- filter replacement frequency: during tests no replacement required after more than 12 months of operation vs replacement everyday before installing the system

- fuel economy from five per cent, up to 10 per cent

- carbon dioxide emissions reduced by more than 300 per cent.

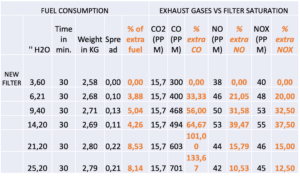

Fuel consumption testing

- tests made with a diesel container on an approved scale at 0.05 pounds (lb)

- timed tests – 30 minutes per test

- stationary John-Deere engine 4 cyl. Tiers 2, 125HP

- measuring equipment 4gaz: TSI Modèle: CA-6703-CA-CALC.

The effects on the health and safety of workers

Environments contaminated by high concentrations of dust can be dangerous for workers.

They can cause respiratory discomfort, damage to the airways, allergic reactions, and even carcinogenic diseases.

To ensure the safety of workers in these environments, systems must ensure the pressurization and filtration of cabins and other workspaces, in order to remove dust particles. In addition, in high exposed environments, employees must always wear masks , even in the cabins.

Epura cabin filtration system in the field: Rio Tinto Canada

- in extreme condition, the filter replacement interval can be multiplied by more than 175

- up to 170 cubic feet per minute, at 100 per cent of fan speed, inside the cabin

- maintains inside cabin pressure above requirement

- Noise level inside cabin under maximum requirement.

Pressure monitoring of Epura cabin filtering system

Epura on the compressor of an overhead crane: Rio Tinto

- following the purchase of a new compressor, the customer wanted to protect critical components from dust and hydrogen fluoride gases and sulfur

- system equipped with a long-life carbon filter to reduce the frequency of carbon replacements

- steel system to resist the gases present.

Epura on electrical cabinets: Elkem

- the existing dust collection system was not efficient and required a lot of maintenance which caused production stoppages for maintenance and cleaning of electrical cabinets in addition to the risk of short circuits.

- this is a dual system equiped with a bi-directional valve to avoid all work stoppage

- the customer’s fan was reused to pressurise the cabinets.

Epura’s areas of use includes mining, port facilities, foundry and castings, demolition, landfill site, national defence, agriculture, peatlands, and forestry.

Ready Resources

Since October 2023, Ready Resources has been the Australasian distributor for both the Epura engine and Epura cabin filtration systems and is working closely with its partners to install the ground-breaking technology to help maintain and cost save their valuable assets.

Ready Resources was founded in the heart of the Pilbara and is a family owned and run business specialising in fixed plant and mobile equipment maintenance.

Striving towards delivering excellence, Ready Resources brings product innovation and technology to the Australian market, introducing Epura by Propulsa Innovations and being its distributor across Australia and Asia.

Ready Resources has the specialist technicians to supply and install the Epura system across all applications in mobile equipment and fixed plant operations.

For enquiries, contact epura@readyresources.com