Plant Wash is bringing the benefits of the Mine Equipment Washer to the Australian mining industry.

Founded in 2020, Plant Wash has emerged as a leading provider of state-of-the-art industrial cleaning solutions throughout Western Australia.

Founded by Leigh Marwick, the company’s inception stemmed from his encounter with the Mine Equipment Washer (MEW) truck at a prominent mining services facility in Pinjarra, WA.

“Initially, my attention was drawn to the MEW in passing, until a colleague highlighted its remarkable capabilities,” Marwick told Australian Mining. “It was then that my interest was truly ignited.”

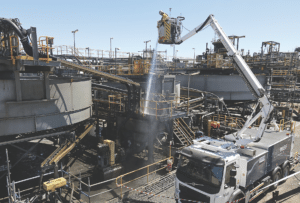

Image: Plant Wash

Marwick subsequently developed an electronic brochure showcasing the MEW truck’s innovative features, strategically disseminating it across various mine sites to foster interest and engagement.

Crafted by Vestergaard in Denmark, the MEW integrates cutting-edge components and technologies sourced from select Vestergaard aircraft service vehicles. Its introduction to the Australian mining landscape was spearheaded by Darryl Smith who, following his tenure in the iron ore sector, sought out pioneering solutions in Germany that he could bring back to the Australian market.

“During his explorations in Germany for transformative technologies, he witnessed a truck performing aircraft washing and de-icing operations at an airfield, which served as a catalyst for inspiration,” Marwick said.

Once Smith returned to Australia, he had a few meetings with Vestergaard and together they came up with the MEW.

Recognising the MEW’s vast potential, Marwick founded Plant Wash to address the evolving cleaning and maintenance requirements within the mining industry.

“I identified the MEW as an ideal solution for servicing fixed process plants,” he said.

“Previous methodologies involving cumbersome scaffolding or hoses tethered to elevating work platforms were markedly inferior in efficiency compared to the MEW’s streamlined approach.”

Image: Plant Wash

Equipped with an elevated work platform (EWP) with a 15m reach and a robust chassis engineered to withstand winds of up to 72km per hour, the MEW boasts a 7000L on-board water storage capacity and a 230kW diesel heater, ensuring water temperatures reach an optimal 95°C for peak performance.

Marwick underscores the MEW’s user-centric design and stringent safety features, including proximity sensors and anemometers, which safeguard operational integrity even in adverse conditions.

Furthermore, the unit’s versatility facilitates online washing, enabling concurrent maintenance activities without disrupting operations.

Describing the MEW as a comprehensive “all-in-one” solution for elevated work, Marwick highlights its efficiency over conventional methods.

“We can deploy directly to site without the need for supplementary equipment,” he said.

In addition to equipment washing, Plant Wash offers vacuum loading services that utilise hydro vacuum excavation trucks, which are remotely controlled for heightened safety and efficiency.

Renowned for their prowess in non-destructive digging, high-pressure jetting and controlled waste removal, these trucks exemplify Plant Wash’s dedication to delivering holistic industrial solutions.

As a proudly family-owned and operated enterprise, Plant Wash places a premium on personalised service and rapid response times.

“Clients can depend on us for bespoke, punctual solutions,” Marwick said. “We are committed to fulfilling their requirements, whether it entails on-site assessments or troubleshooting.”

In essence, Plant Wash typifies innovation, efficiency and personalised service, catalysing a paradigm shift in industrial cleaning within WA’s esteemed mining sector.

This feature appeared in the May 2024 issue of Australian Mining.