Chile’s Antofagasta Minerals (AMSA) is one of the world’s leading copper producers and as such has one of the largest ultraclass mining fleets in the world. Its operations include Centinela, Los Pelambres, Antucoya and Zaldivar plus it has massive expansion plans underway – notably its US$4.4 billion Nueva Centinela project, which includes the expansion of the Esperanza Sur and Encuentro open pits and a second concentrator, all of which will produce an additional 170,000 copper equivalent tonnes per annum.

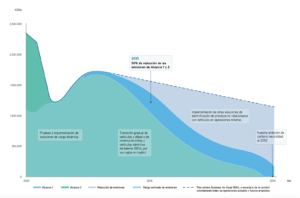

So AMSA’s decisions relating to reducing mobile fleet emissions have real significance. Its strategy was broadly laid out in its recently published Climate Action Plan, subtitled ‘Our path to decarbonisation.’ Starting already in 2024, its decarbonisation initiatives will begin to influence its Scope 1 and 2 emissions curve by changing the trajectory downwards – primarily with mining trucks through a combination of trolley assist and battery conversion.

By 2030, AMSA anticipates the commercial availability and economic viability of battery kits, allowing the beginning of the conversion of its existing fleet of mining trucks. By 2035, it aims to reduce Scope 1 and 2 emissions by 50% compared to the 2020 baseline, but points out they very much depends on the availability of technically and economically feasible solutions by OEMs for the replacement of mining equipment before 2030, and the progression of Chile’s energy infrastructure in line with energy demands.

It adds: “The execution of our plan depends on many factors outside our control, including technological readiness for fast charging solutions, flexible trolley system infrastructures, cheaper batteries, and the feasibility of retrofitting for mining equipment. Our plan to meet our 2035 target depends on original equipment manufacturers submitting viable proposals to replace mining equipment by 2030, and on the country’s energy infrastructure evolving to meet the demands of the energy transition. The technology is expected to continue its evolution, providing electric charging proposals that allow us to charge a truck in less than 30 minutes and batteries with greater autonomy than those available in the industry today.”

AMSA’s Scope 1 & 2 projected emissions curve based on current strategy and enabling conditions

The company then states: “Both our plan and the industry’s decarbonisation plans depend on the cost of electrical energy and its transmission, which must decrease or at least remain within the ranges we see in today’s market. If these enabling conditions do not develop in line with our current expectations, then they would impact our ability to meet our 2035 target, considering the specific details of our situation and the broader context of the energy landscape.”

Looking at trolley, AMSA says its strategy is to start with the feasibility analysis for dynamic loading solutions and define an appropriate recommendation for each of its mining plans. “This pre-feasibility analysis is strongly linked to the success of the tests carried out by the Group on the trolley system and other technologies, maintaining our flexibility to take different paths as technology advances.”

It continues: “Subject to feasibilities being approved, we hope to begin implementing trolley systems as a first step in the electrification of our operations. We aim to develop our knowledge of trolley systems through testing in our operating conditions, validating our assumptions and helping us estimate potential impacts on mine designs. During this same period, we expect stationary charging to increase charging speeds, giving us another tool that will be integrated into the final electrification model that is expected to support all-electric trucks.”

Returning to the topic of the trucks themselves: “Our goal is to upgrade our truck fleet to battery-powered vehicles. We believe that trucks purchased towards the end of the decade will be pre-equipped for future modifications to low-carbon technologies. This transition timeline is highly dependent on the dynamic and stationary charging solutions described above, as well as the technology being available at a competitive cost.”

AMSA will be discussing some of these plans at the Electric Mine 2024 conference, coming up soon at Crown Perth, Western Australia, May 21-23. Specifically, on Day 1, May 21 at 11:20 in the Surface Mining stream, Tomás Nass, Decarbonization Manager at Antofagasta Minerals Chile will be speaking on ‘AMSA decarbonisation roadmap meets ABB technology partner ecosystem for electrification’ together with co-speaker, Ratna Kanth Dittakavi Global eMine™ Sales Manager at ABB. You can still register for the event at www.theelectricmine.com