Hazemag allmineral’s mineral processing technologies are helping mining companies reach high efficiency across a range of commodities.

With 500 employees across 11 countries, Hazemag remains strong after 180 years in business.

“We started in the aggregate recycling business, where we recycled rubble from World War II by crushing, recycling and separating the materials to retrieve the wood and iron from the aggregates, and then reused those aggregates,” Hazemag allmineral Australia managing director Teddy Craies told Australian Mining.

“As the business grew, it also acquired other companies like allmineral.”

Hazemag allmineral has two aspects to it: aggregate and mining in the Australian quarry, iron ore and coal sectors.

“The crushing and mineral process are two separate functions, so we’re covering both areas, providing solutions from a single source,” Craies said.

“Crushing reduces the product size and then (the mineral) is separated through other processing mediums, but there are some materials that are very hard to separate.”

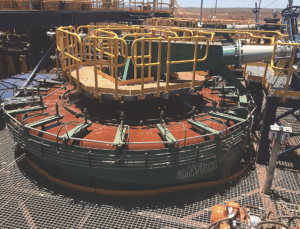

Image: Hazemag allmineral

This is where allmineral’s allair and allflux systems can help.

The allflux is a wet mineral processing solution suited to a wide range of commodities and materials, including iron ore, coal, heavy mineral sands and slag.

The allflux has three separation levels for the material to pass through and uses fluidised bed technology with autonomous heavy media for the separation and hydraulic classification of slurried fines.

“The allflux was an idea that originated in 1988 and was continuously developed,” Craies said. “It can now deliver up to 2000 cubic metres per hour in volume production.”

The allflux is unique in its ability to create two product streams – one coarse and one fine – from a singular feed source, reducing the need for further downstream processing, saving cost and infrastructure footprint.

In the coarse sand space, the feed sludge creates an upflow causing light, fine particles to rise and heavy particles to sink and be drawn off.

In the fine sand chamber, the fine particles enter with the light material and form an autogenous fluidised bed to allow the light material to float and overflow with the upflow water.

The discharge of coarse material out of the central hopper is automatically controlled by an analogue system.

“The allflux allows companies to optimise their extraction system because it helps extract as much material as possible,” Craies said.

Hazemag allmineral Australia project and service engineer Jaco Botha said the allflux comprises three separations in one unit: two product streams and a waste.

“You have a coarses section, a middlings section and the waste that comes with this,” Botha told Australian Mining. “This three-step process occurs with no moving parts. That’s the biggest benefit of the allflux.”

Opposite to the allflux is the allair, a dry mineral processing solution from allmineral best suited to the coal and recycling sectors.

“The allair is a jigging machine,” Craies said. “Its particle size ranges from 1mm to 50mm, and its throughput rates ranges from 20 to 100 tonnes per hour per machine.

“It’s a compact, mobile unit that can be easily transported from site to site, whereas the allflux is a fixed system with more infrastructure.”

Craies described the allflux and allair as “niche” products requiring little maintenance.

“Generating two products from the one unit, the allflux is mirroring what the customer needs in terms of power consumption and costs, enabling customers to save on capex (capital expenditure) and opex (operational expenditure),” Craies said.

“Both of the products are environmentally friendly. While the allflux reuses water during its process, the allair mobile solution requires no water.

“Parts are also refurbished so there’s minimal waste, while there is reduced need for consumables, making the cost of operation far more economical.”

This feature appeared in the April 2024 issue of Australian Mining.