Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

One of the interesting things I’ve been doing is participating in a review group for a European study on heavy vehicle decarbonization comparisons and simulations. That means, among other things, that I’m poking at the assumptions being used.

As the paper is in review and assumptions are being tested and improved, I won’t identify the author or organization at this time. This isn’t about them being wrong or right, but about a bunch of assumptions being made about fuel cell heavy vehicle maintenance that don’t stand up to scrutiny, yet are in a lot of studies that are considered credible.

Let’s start with first principles. A heavy duty fuel cell vehicle like a freight truck or transit bus is a battery electric vehicle with added fuel cell drive train components. That means that the battery power train has batteries, an electricity charging system with no moving parts except the flap over the plug, a power management unit to move electricity across wires to the motor, and a motor. There are sensors, computerized controls and the like, but very few moving parts and very little that requires much maintenance. That’s born out by maintenance studies of pure battery electric vehicles.

A fuel cell vehicle is a battery hydrogen hybrid vehicle. It adds a sophisticated 700 atmosphere hydrogen tank or an even more sophisticated liquid hydrogen tank with pressure sensor and relief systems, a complex hydrogen fuel movement system which has to deal with very large pressure changes in the case of the pressurized tanks or very large volume and hence pressure changes as liquid hydrogen is warmed to gaseous form, very large thermal management challenges and hence thermal management sensors, actuators and components in both cases, an expensive and life-limited fuel cell which requires pure hydrogen and and clean air, an air intake and filtering system as a result and an exhaust system for moving the resultant water from the fuel cell out of the vehicle without freezing hence a heating solution.

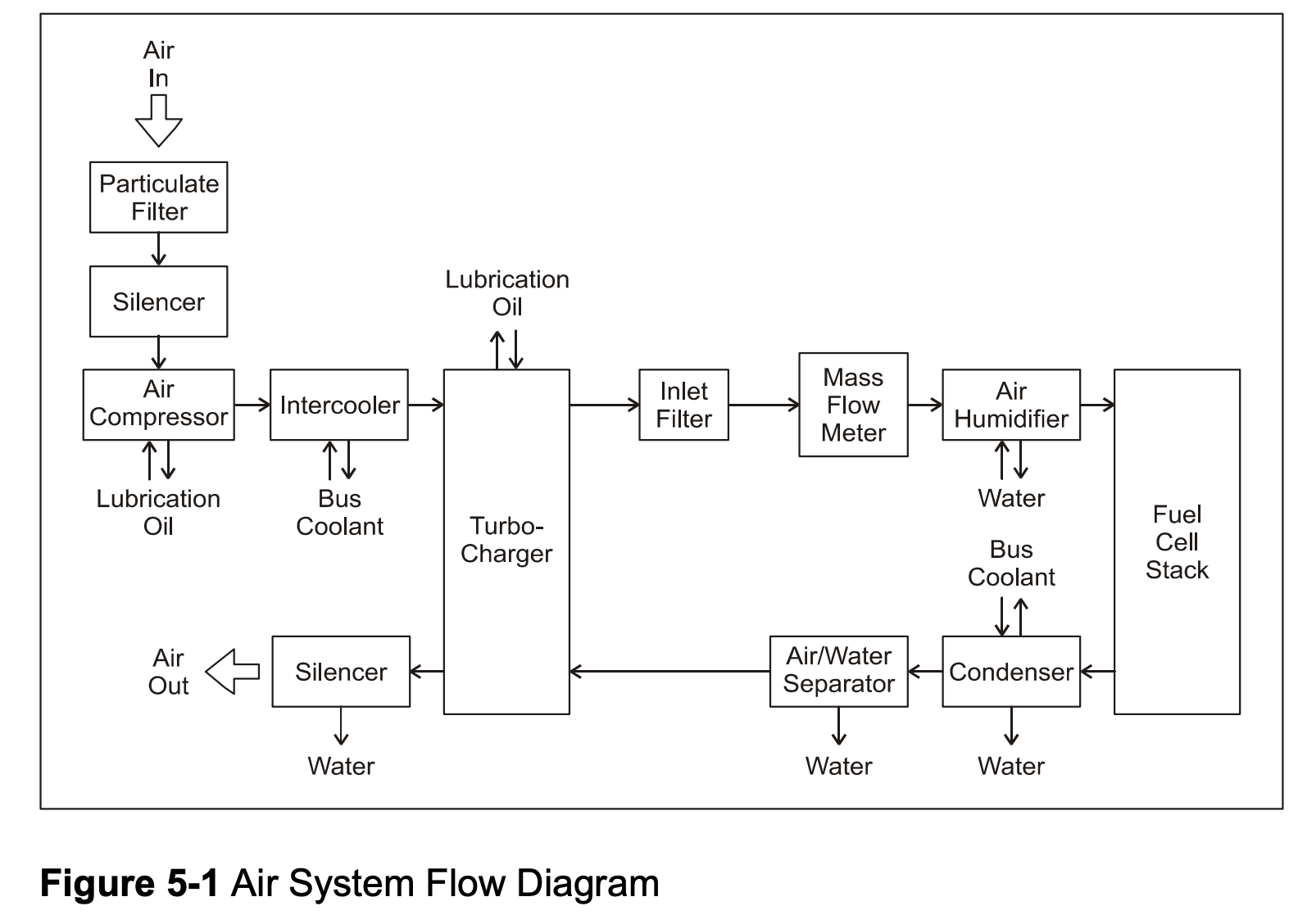

This diagram of just the air management process, which isn’t required for battery electric vehicles remember, should make it clear that a fuel cell vehicle’s added components are non-trivial. There are many more points of potential failure and many more things that require scheduled maintenance.

The closest example is hybrid electric vehicles. The data from light vehicles shows that maintenance on the drive train costs a lot more on hybrid vehicles than on pure battery electric vehicles, about the same as internal combustion vehicles.

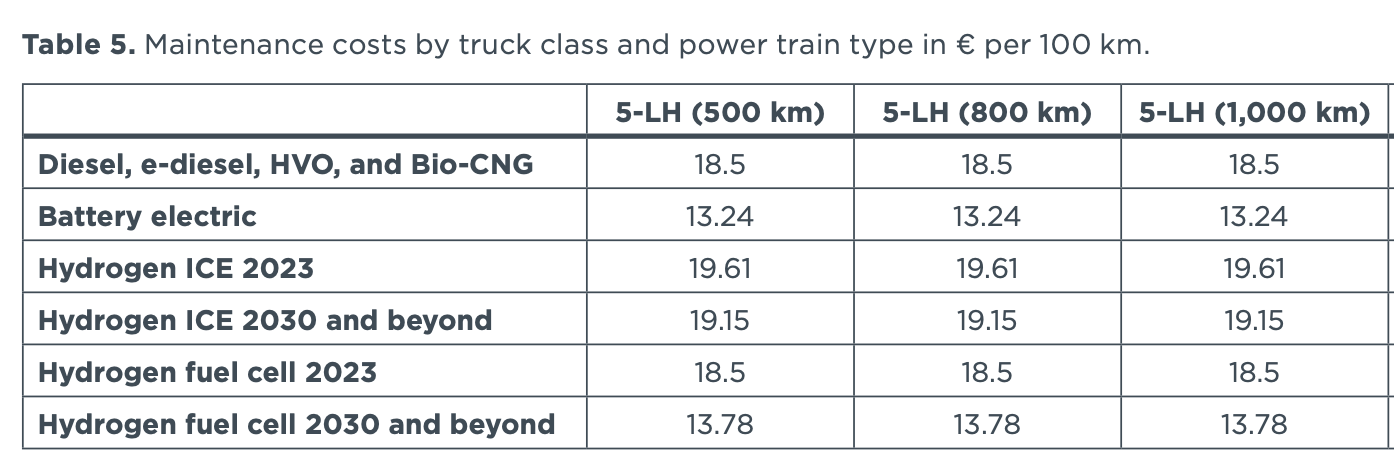

One of the things I criticized the International Council on Clean Transportation’s deeply flawed trucking study about last year was that they had significant maintenance cost improvements for hydrogen drive train trucks and none for battery electric trucks. In fact, they assumed that heavy duty, long-range trucks — the only segment where some organizations still hold out hope for fuel cells — would have very similar maintenance costs to battery electric after 2030, and equivalent maintenance costs to diesel trucks immediately.

The numbers are all in euros per 100 kilometers.

When I first reviewed it, I was scratching my head about giving the benefit of the doubt to maturation of hydrogen fuel cell trucks vs battery electric trucks. After all, fuel cell buses have been operating around the world in trials since 2000, and fuel cell fork lifts for longer. Battery electric trucks and buses are comparatively new.

But now I’m scratching my head about why everyone believes hydrogen fuel cell heavy vehicles will be low maintenance at all.

I’ve been collecting anecdotal data about maintenance costs. The Pau, France fleet operator made it clear when they ditched the hydrogen buses in 2023 after four years of operation that they had been very high maintenance, and that keeping them running was a constant challenge.

“The production station has more problems than expected and the buses have lots of very small breakdowns. As for me, I spend three quarters of my days there even though it is only one of 17 lines!”

Similarly, the Whistler, BC experience from a decade earlier found double the maintenance costs, per Ballard itself.

According to Burnaby’s Ballard Power Systems, which manufactures fuel cell engines, Whistler’s hydrogen buses cost $1.34 per kilometre to maintain, versus 65 cents per kilometre for diesel-powered buses.

Two bus operators, separated by a decade and an ocean, both had identical experiences with buses from different manufacturers. But still, anecdotal. If that was all the data, I would write it off to a couple of bad experiences.

But when a rail OEM sales executive for Stadler in Germany has this to say about his own products, I thought something was up.

“In addition, hydrogen fuel cells require significantly more maintenance than a batteries alone, requiring replacement within three years on average.

“Because of this and the hydrogen tank on board, the maintenance effort is of course more complex compared to battery trains,” Obst explained, adding that hydrogen trains also require a battery for back-up power.”

As a result, when I saw very low maintenance costs assumptions in the study I’m reviewing, I provided this material and suggested that assumptions of almost identical maintenance costs was inappropriate. The lead researcher pointed at the source, so I went to that. It was a German working group study, in the same effort as the study I assessed a couple of months ago.

The study, translated thanks to a very handy online webpage which is going to be sending me pleading emails to give them money forever now, was the 2020 Workshop Report Changing the Drive of Commercial Vehicles: Ways to Decarbonize More Difficult Trucks with a Focus on Electrification from the German National Platform: The future of Mobility effort.

I dove into that expecting to find a reference to studies and empirical data. What I found was that three researchers from two institutions — Wolfgang Schade of M-Five and Patrick Fieltsch and Heike Flamig of the • Technical University of Hamburg had provided maintenance assertions without reference or citations. There was nothing in the bibliography that might explain them either. I couldn’t find any other studies in German that might have been the source, but Googling in German isn’t my top skill, so I may have missed something.

So we have ICCT, M-Five and TUHH all asserting what appear to be low numbers for maintenance and so far no data or studies backing them up.

I went back to the ICCT TCO study to look at their maintenance numbers, and it cites another 2023 publication by the lead author, so I went to look at that study. It points to a University of California, Davis paper from 2022 by Wang et al, Estimating Maintenance and Repair Costs for Battery Electric and Fuel Cell Heavy Duty Trucks.

Does it have data? No, no it doesn’t. It lists the reports it drew on, stated clearly that there was no data to draw on and that everyone was assuming that fuel cell trucks would be about the same as battery electric trucks or maybe a bit more expensive.

So far I’m half a dozen reports in on two continents in two languages and haven’t found anything except guess work. But I have two quotes from bus fleet operators, a vehicle type that is strongly adjacent and similar to heavy duty trucks with a high duty cycle, a decade apart making it clear that they very high maintenance costs and a quote from a train OEM executive who makes it clear that his fuel cell product’s maintenance costs are much higher as well. In fact, he says no one would buy it unless the request for proposal explicitly called for hydrogen trains and nothing else.

This led me to go and look at fuel cell bus maintenance data, with the hope that despite all of the failures that have been swept under the carpet in the 25 years that hydrogen buses have been trialed and abandoned in dozens of places around the world, someone would have actually captured some data.

And lo, California came through. As always with the USA, they publish everything about themselves, making data available for analysts like me to try to extrapolate to places with vastly lower budgets or any sense that everyone will care about them.

I found three studies of bus fleets in three different transit organizations in California,

This US OSTI study of a fleet of ten fuel cell buses in Oakland, California for the full year of 2020 found that the average maintenance for distance traveled was much higher than the maintenance costs for diesel buses, about 59 cents per mile vs 35 cents per mile. Incidentally, that was very close to the hybrid battery diesel fleet, which was at 62 cents.

This study from Southern California by NREL of of 10 fuel cell buses for 16 months found costs per distance traveled lower than the OSTI study at 42 cents per mile, but still higher than the 35 cents per mile diesel baseline. Notably, propulsion related maintenance was 37.3% of total.

This NREL study covering six years of maintenance for fuel cell buses in Riverside County, the long-running Sunline County, Coachella adjacent city, found maintenance costs were 2.5 times higher for the fuel cell fleet than the older CNG fleet for the period, 56 cents per mile or very close to the first study.

A bit more searching found no other empirical data available in English on maintenance costs.

But now the data set is the following:

- Bus fleet studies from California totaling over eight years between three fleets found much higher maintenance costs than for a diesel baseline.

- Published articles with quotes from Whistler, BC and Pau, France make it clear that maintenance costs for their bus fleets, both the 14 year old Whistler experience and the one year old Pau experience were very high. A decade with zero movement is not indicative of a maturing industry.

- The Stadler executive on record as saying that maintenance costs are much higher for their brand new trains.

To me what appears to be clear is that there are a bunch of transportation researchers who are all guessing based on literally no evidence that clearly more complex and failure prone hydrogen trucks will be about the same as much simpler battery electric trucks, or maybe a little more expensive. Further, they are all assuming that they will be much cheaper to maintain than diesel trucks, where at least they have the transmission system to point to.

None of them appear to have gone to look at maintenance data for closely adjacent hydrogen buses where there is a 25 year history, or looked at rail operator statements, although that quote was fairly recent. None of them appear to have gone to OEMs that have run trials of hydrogen trucks and asked about maintenance experiences. None of them appear to have noticed the $100,000+ fuel cell replacement charge a Hyundai car owner had and started asking questions.

As a reminder, virtually all of these buses have Ballard fuel cells in them, technology that Ballard has been selling globally for over 25 years, with losses of $1.3 billion since 2000. This is not an immature technology, it just fails to commercialize at scale after every single trial.

Like the assumption of cheap green hydrogen, the assumption of low-maintenance fuel cell trucks does not stand up to the slightest of scrutiny. Road freight researchers in the 2010s made some baseless and low-ball assumptions and in the 2020s those assumptions are considered valid because they’ve been cited so often.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica TV Video

I don’t like paywalls. You don’t like paywalls. Who likes paywalls? Here at CleanTechnica, we implemented a limited paywall for a while, but it always felt wrong — and it was always tough to decide what we should put behind there. In theory, your most exclusive and best content goes behind a paywall. But then fewer people read it!! So, we’ve decided to completely nix paywalls here at CleanTechnica. But…

Thank you!

CleanTechnica uses affiliate links. See our policy here.