Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Building on many incredible technological innovations, solar energy is set to break all-time records with 413 GW expected to be deployed globally in 2023. Similarly, the stationary battery storage market is expected to grow 26-fold from the 56 GWh globally deployed at the end of 2021 to 1,432 GWh that Bloomberg NEF expects to see cumulatively installed by 2030. Once battery demand for the electric mobility sector is factored in, the market for batteries is even larger. As one of the main enabling technologies for accelerating the adoption of variable renewables, any technological breakthroughs in battery storage hold vast potential to accelerate the transition to lower carbon energy systems.

One of the things that has excited me the most over the past eight years is seeing the evolution in power electronics that electrically connect solar and battery storage to the grid. The original approach in solar sees solar panels connected to the grid using central string inverters. However, as the industry matured, more advanced approaches which provide significant value add were developed. Companies such as Enphase and SolarEdge revolutionized the sector by commercializing distributed approaches that placed electronics at each solar panel, allowing optimization of the system to unlock additional power, lifetime, and installation flexibility.

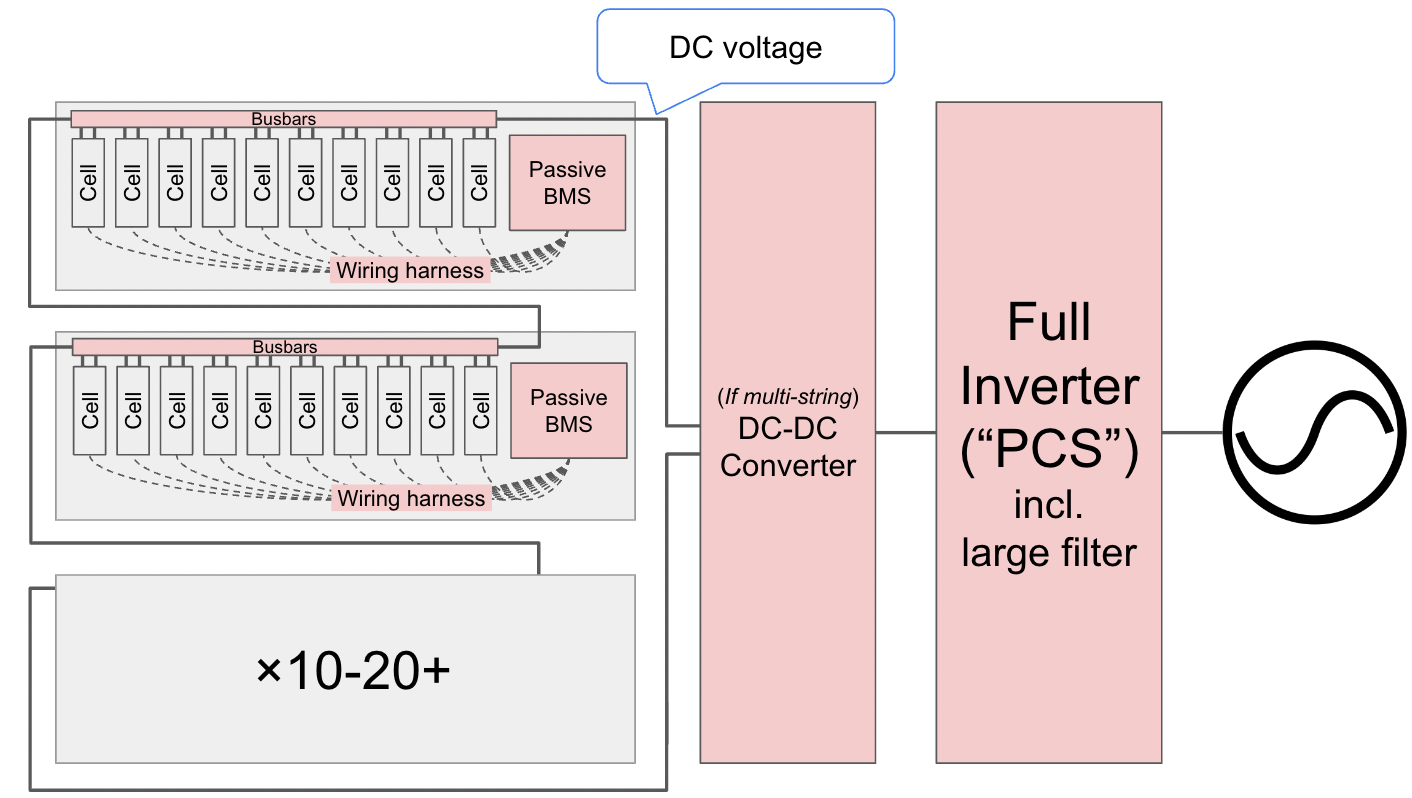

Likewise, for batteries, the most common initial setup has used central battery inverters. This approach is not only suitable stand-alone, but can also be coupled to solar inverters. As such, it provides flexibility in component choice but has the downside of combined battery and solar systems being quite costly and requiring lengthy installation processes. Hybrid inverters are one approach that has gained traction to improve this by combining the separate battery and solar inverters into a single, more complex system that integrates an inverter and a DC-DC converter to connect both battery and solar at shared sites.

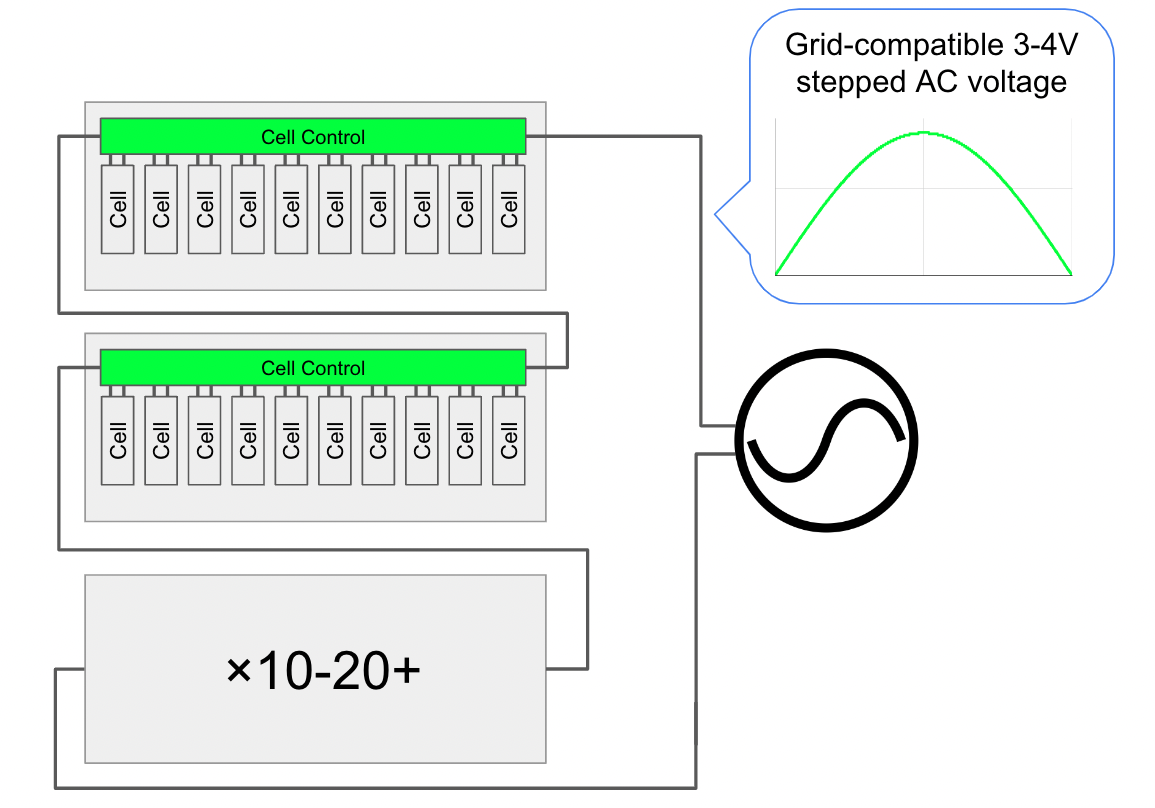

But what if this could be simplified even further by doing away with the battery inverter completely to unlock additional lifetime, cost savings, and further performance benefits? This is what several established firms and high-growth startups are working on. Using more advanced versions of battery management system electronics, typically a subordinate system supporting battery safety, they can demonstrably achieve an inverter-less connection to the grid. Taking a lesson from the additional performance and lifetime distributed approaches unlocked in solar, essentially these solutions use distributed control of the batteries within a system in a way that creates step-wise sine waves directly from the batteries, without the need for an inverter. The solutions that have been developed and are rapidly being commercialized fall into two prospective levels: module-level control, and cell-level control.

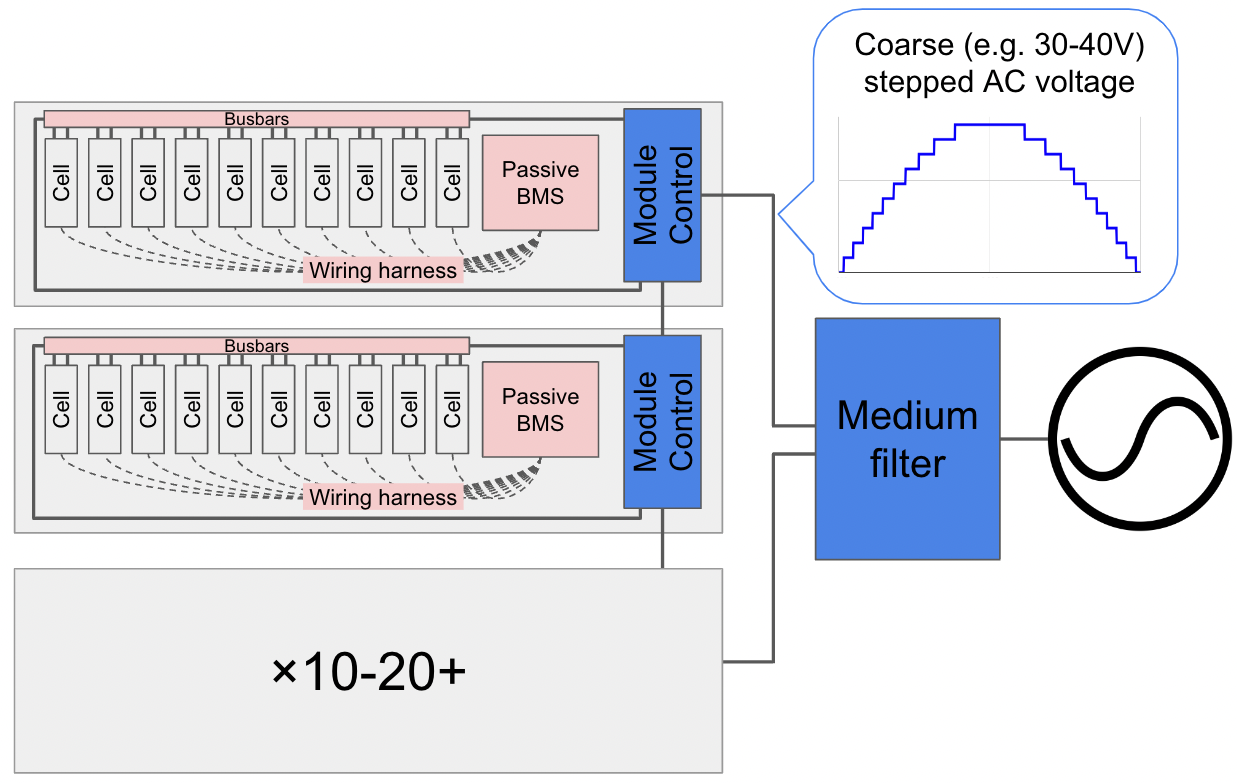

1) Module-level Battery Management Inverters (MBMIs)

MBMIs are a partway step between the conventional combination of a passive battery management system with a centralized inverter, and the full-benefit cell-level battery management inverters described later in this article. As shown in the diagram, MBMIs maintain the BMS inside battery modules but replace the central inverter with a collection of module-level controllers that provide for example a 30-40V step wave output, thus requiring only a moderate-sized filter for a smooth sine wave. In both the module- and cell-level case, the AC sine wave connection is fully bidirectional, suitable both for charging and for discharging the battery.

The module-level approach is favored by the majority of the firms in the current ecosystem as it has perhaps a lower barrier to entry, requiring fewer switching elements, less complex communication and algorithms, and is therefore faster and easier to develop. This also maintains the current status quo which maintains some separation between the battery management system (BMS) and inverter. It also is particularly suitable for easier integration of pre-welded second-life batteries.

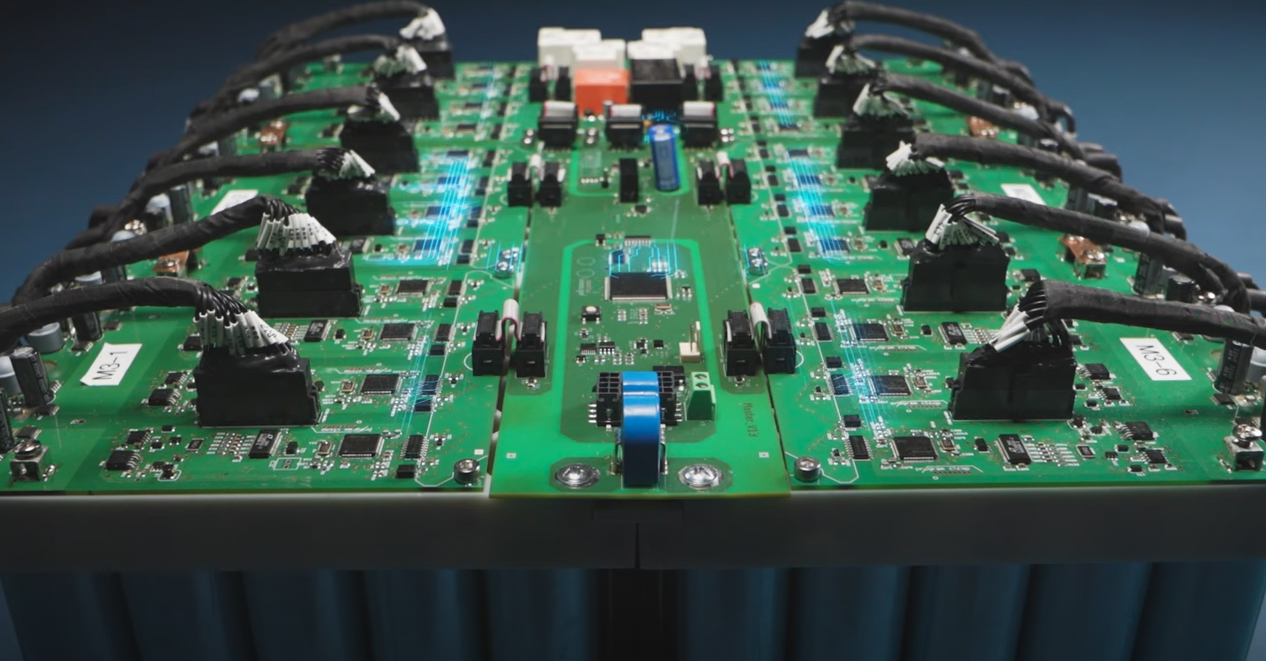

Leading companies in module-level control include German companies Sax Power and Instagrid, which both have residential scale battery products in the market and are working on industrial systems. Other key companies in this sector have yet to bring a product to market. These include global automotive Stellantis working with leading battery company SAFT on this as a “paradigm shift in the design of electric [vehicle] powertrains.” Toyota and Japanese utility Jera have deployed a utility-scale pilot. US growth company Element Energy is developing reused grid-scale storage. And German company Stabl is working on reused commercial batteries, among numerous other module-level companies identified in the sector overview below.

2) Advanced Cell-level Battery Management Inverters (CBMIs)

CBMIs take this concept to its ultimate stage of achieving control of every series-connected battery cell. As seen in the diagram, this architecture elegantly orchestrates cell voltages to directly achieve grid-suitable system AC input and output without any other interim steps, doing away with the need for an external inverter entirely. This means that the system can be built without large capacitors and inductors — in fact, systems can be built without a single electrolytic capacitor. This results in even stronger potential for improved energy density, alongside increased efficiency and much longer electronics lifetime. This architecture also entirely removes the need for passive cell balancing systems and related energy losses. By disconnecting individual cells as opposed to entire modules, it further has the added advantage of helping to achieve a higher level of redundancy with fewer required battery cells in the system. The CBMI approach also suits novel battery chemistries where cell-terminal switching or the ability to disconnect cells is a critical feature.

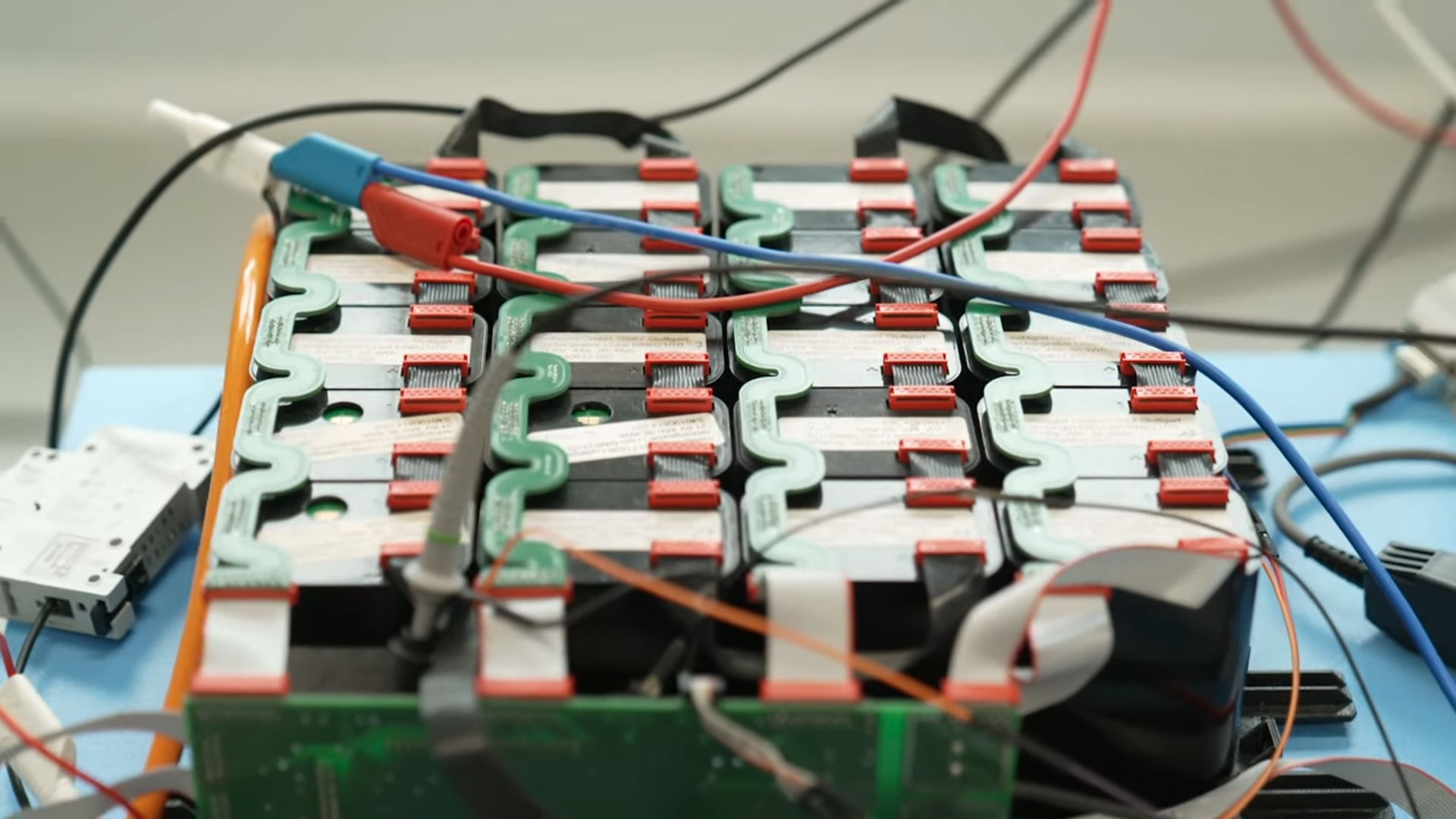

Although the barrier to entry for cell-level control is much higher than for module-level, there are currently two firms leading this even deeper technological advancement. These are Canadian-listed company Exro Technologies, and Toyota-backed Australian company Relectrify. While Exro Technologies is presently working through certifications for an industrial product, Relectrify has already demonstrated its technology with leading power companies globally, earlier this year achieved full certifications, and has since deployed its technology at a substantive volume of industrial products in the US, Japan, New Zealand, and Australia.

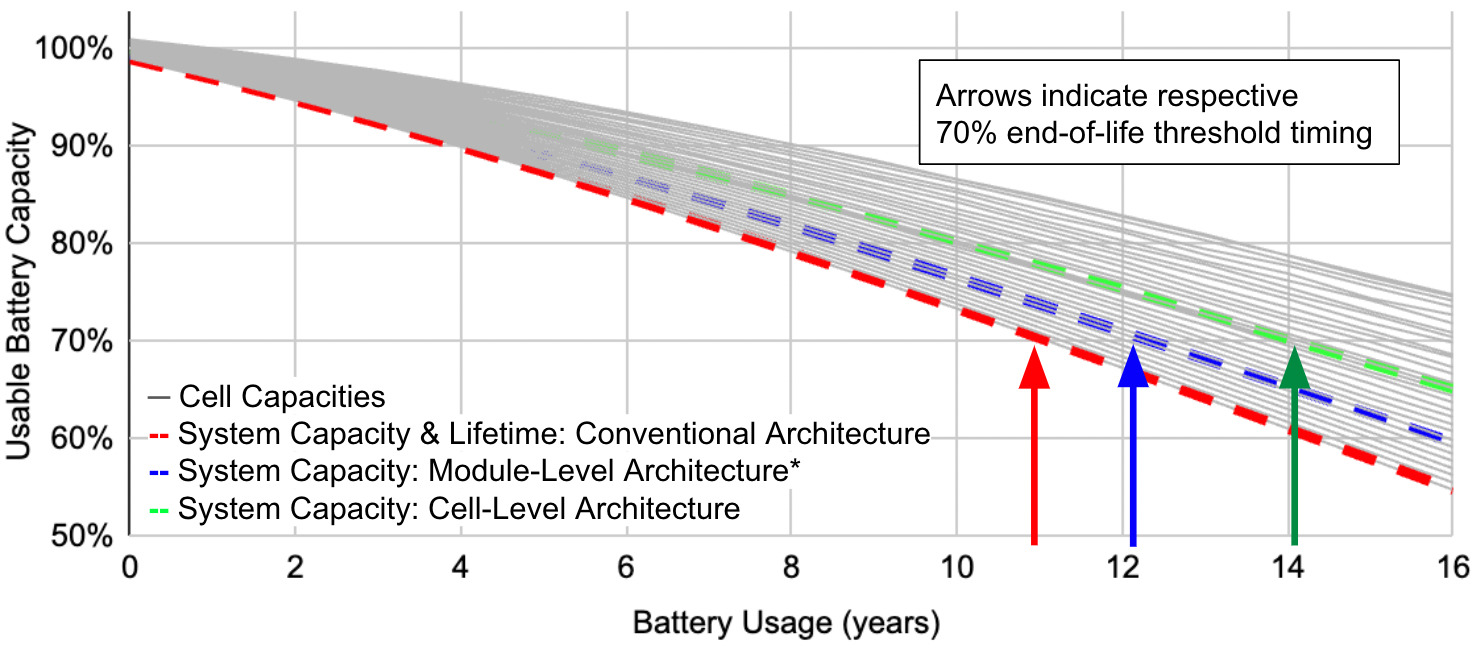

Alongside supplanting a conventional inverter with associated cost, efficiency, and space benefits, potentially the largest upside of these distributed approaches is the extra battery system capacity and lifetime unlocked. Conventional batteries are similar to a string of traditional festive lights as they are limited by the weakest series element of the hundreds of series battery cells in the string. Systems with module-level control are better in that they are only limited by the weakest of the ten or so cells in the module. In cell-level controlled systems, this limitation is entirely unlocked and each cell can be used to its full potential. The result, for example, the battery scenario modeled as shown in the below diagram is the potential for module-level control to unlock battery operating life from under 11 years for conventional batteries to above 12 years (assuming 10 cells per module and a mid-way scenario for how cells are distributed within modules). Lifetime is enhanced even further with cell-level control, which has potential to unlock battery operating life from under 11 years for conventional batteries to over 14 years, or around 30% by accessing each battery cell. In a world seeing battery gigafactories being built in many geographies, this ability to get additional lifetime from batteries without any change to their chemistry or manufacturing process seems highly valuable.

As a separate benefit, by allowing cells of different capacities to be integrated together without being limited by one another, this additionally opens up the possibility of using batteries outside the tight manufacturing tolerances required to be considered manufacturing yield for normal battery systems, representing up to 10% of Western mature battery factories and up to 50% of the output of new factories (link).

Combining the public testing reports and statements by the companies involved in this rapidly developing technology frontier, the full suite of benefits relevant for the ultimate outcome of cell-level control includes all the below:

- Increased battery lifetime by unlocking access to the full capacity in each cell

- Increased electronics lifetime by entirely avoiding the need for electrolytic capacitors

- Reduced electronics cost due to inverterless AC

- Reduced cost of cells by enabling batteries with wider spread in capacity and other characteristics to be used

- Enhanced safety responsiveness since any suspect cell/module can be bypassed

- Higher reliability given any failed cell can be bypassed individually

- Higher energy density due to inverterless AC

- Higher efficiency due to inverterless AC and completely removing passive balancing losses

- Accelerated fast-charging by bypassing charged cells to maintain a higher current

- Improved battery maintenance, including wider compatibility with replacement batteries

- Ability to combine battery segments of differing chemistries, usage or other characteristics

- Enablement of new battery chemistries, which require distributed control

In its entirety, this benefits list sounds almost too good to be true. However, the number and caliber of companies working on this topic, and the progress by some companies that have real products in customers’ hands today, adds credibility to the opportunity these distributed battery management inverters have to offer. Having seen the value that distributed power electronics, for example by Enphase and SolarEdge, unlocked in the solar market, it will be very exciting to watch this space in batteries shape up in the years to come.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Our Latest EVObsession Video

I don’t like paywalls. You don’t like paywalls. Who likes paywalls? Here at CleanTechnica, we implemented a limited paywall for a while, but it always felt wrong — and it was always tough to decide what we should put behind there. In theory, your most exclusive and best content goes behind a paywall. But then fewer people read it!! So, we’ve decided to completely nix paywalls here at CleanTechnica. But…

Thank you!

CleanTechnica uses affiliate links. See our policy here.