In this exclusive interview, DEScycle’s CEO, Dr. Leo Howden, outlines how deep eutectic solvent (DES)-based ionometallurgy is moving from lab promise to industrial reality, with modular, co-located plants, closed-loop solvent and water management, and a hybrid go-to-market model to scale globally. The conversation explores priorities in throughput scaling and automation, lessons that shaped the Teesside demo, digital traceability for payability, and partnerships focused on securing feedstock as the critical lever for commercial success.

DEScycle is a UK-based deep-tech company pioneering DES-based metal recovery technology and a dual award winner in the 2025 Mining Technology Excellence Awards.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Mining Technology (MT): Congratulations on winning the R&D and Environmental awards. How do these awards validate your long-term vision for DES-based ionometallurgy?

Dr. Leo Howden: These awards affirm that deep eutectic solvent (DES) chemistry has moved beyond the lab and is now recognized as a commercially viable foundation for low-carbon metals processing. Our vision has always been to redefine hydrometallurgy, or rather Ionometallurgy, through tunable, recyclable solvent systems that enable circular metal recovery. Recognition from Mining Technology validates not just the science, but the broader industrial and environmental relevance of DES-based ionometallurgy.

MT: What are your top R&D priorities now—chemistry tuning, throughput scaling, automation, or new feedstocks—and why?

Dr. Leo Howden: Our immediate focus is on throughput scaling and process automation, ensuring the chemistry performs consistently under industrially relevant conditions. In parallel, we’re refining solvent tuning to optimize selectivity for diverse waste streams. The combination of chemistry robustness and engineering scalability is what enables rapid replication across new feedstocks and geographies.

MT: What were the toughest engineering hurdles you faced in moving from lab to pilot, and how did those lessons shape the demo-plant design?

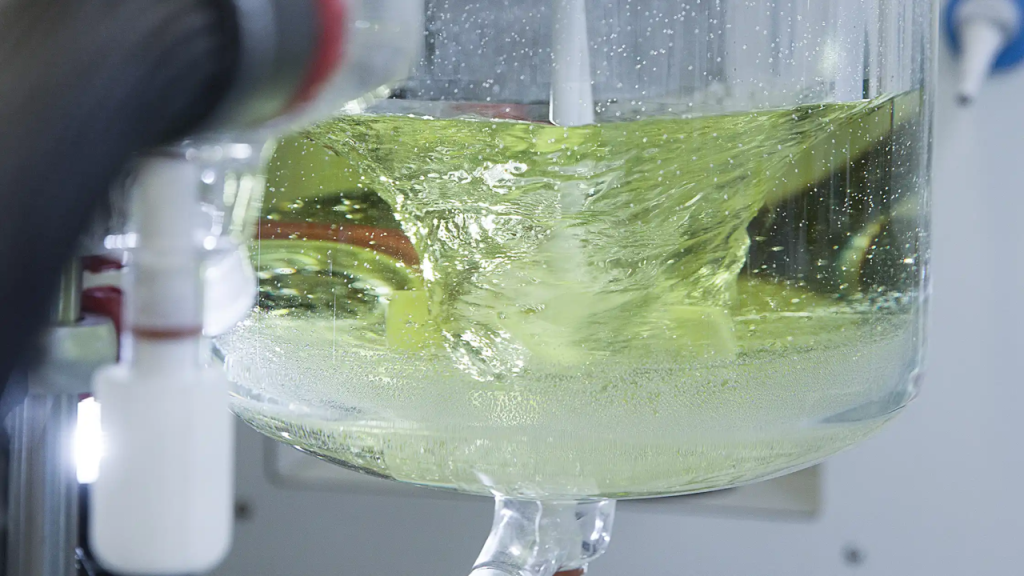

Dr. Leo Howden: Transitioning from batch to semi-continuous operation requires managing mass transfer, phase stability, and solvent recirculation at scale. We encountered challenges around solids handling, filtration, and temperature control that influenced our modular plant design. Those lessons drove us to adopt closed-loop solvent management now embedded in the Teesside demo architecture.

MT: Your model emphasizes modular, co-located deployment. What operational advantages does this offer versus centralized smelting hubs?

Dr. Leo Howden: A modular, co-located approach reduces transport emissions, improves feedstock traceability, and aligns processing capacity directly with local material flows. It allows rapid deployment, lower capex per unit, and flexibility to match regional waste compositions. Unlike centralized smelting, our approach captures value locally—supporting regional circular economies and decarbonizing supply chains simultaneously.

MT: How are you addressing materials-of-construction and corrosion management to ensure solvent longevity and consistent performance at scale?

Dr. Leo Howden: Corrosion management is a key design pillar when working with DES, as it is extremely effective at dissolving metals. We’ve completed extensive compatibility testing with stainless steel, polymers, and coated materials under continuous DES exposure. The selected materials minimize ion leaching and maintain solvent integrity. Combined with condition monitoring and preventive regeneration cycles, this ensures solvent longevity and stable metallurgical performance over thousands of operating hours.

MT: Can you outline your solvent regeneration and water-recovery approach, and how it underpins the closed-loop claims?

Dr. Leo Howden: The exact process is sensitive IP. Because the solvent is not consumed as acids are, the DES platform enables full solvent recycling, making the process highly efficient. Water recovered during processing is recirculated to maintain solvent composition, ensuring minimal effluent generation. This closed-loop solvent and water management not only cuts waste but also proves that clean hydrometallurgy can be both circular and economically competitive.

MT: The e-waste value chain is fragmented. Which commercial structures—JVs, licensing, or build-own-operate—best fit your route to market, and why?

Dr. Leo Howden: We see a hybrid model emerging: build-own-operate for strategic hubs where we need to validate performance and economics, and joint ventures or licensing for regional replication with trusted partners. This ensures quality control during early rollout while leveraging partners’ access to feedstock and market channels for scale.

MT: You’ve validated multiple feedstocks. Which non–e-waste applications are nearest to commercialization, and what criteria guide prioritization?

Dr. Leo Howden: Our next targets are batteries, PV panels, and magnets, each of which align with our chemistry’s strength in selective metal recovery from complex matrices. We prioritize applications where DES offers a clear carbon, cost, or selectivity advantage over incumbent processes and where the market for recovered metals—like cobalt, nickel, and rare earths—is strong and traceability-driven.

MT: How will you integrate with upstream recyclers on data, sampling, and payability to create transparent, bankable offtake terms?

Dr. Leo Howden: Transparency is key to scaling. We’re developing digital integration protocols with recyclers that combine real-time assay data, blockchain-based traceability, and automated payability models. This ensures confidence in yield prediction and enables financiers to underwrite feedstock and offtake agreements with minimal risk.

MT: With backing from Cisco and Mitsubishi, what strategic contributions beyond capital are most critical to scaling DEScycle?

Dr. Leo Howden: Feedstock, feedstock, and feedstock. This is the biggest commercial risk for any recycler, and cultivating strategic partnerships driven by transparency, sustainability and profitability is our key commercial focus.

MT: What are the key milestones and decision gates between the Teesside demo (TRL7) and first commercial final investment decision (FID), and how will you de-risk them?

Dr. Leo Howden: Post-Teesside, our milestones include:

- Extended operation to validate solvent stability and product quality;

- Independent techno-economic and lifecycle assessment (LCA) verification;

- Engineering package finalization for scaling;

- Offtake and financing agreements

We’re de-risking each gate through third-party validation, technology pilots, and strategic partnerships that share both capital and operational learning.

MT: How are you engaging with regulators on permitting, and what evidence has been most persuasive in demonstrating environmental performance?

Dr. Leo Howden: We’ve engaged early with regulators, sharing emissions, effluent, and lifecycle data from our pilots. The most persuasive evidence has been the absence of hazardous reagents, closed-loop water use, and carbon intensity that is an order of magnitude lower than smelting. Transparent data sharing will build strong regulatory confidence that DES ionometallurgy sets a new environmental benchmark.

MT: Local siting is core to your model. How do you approach community engagement and workforce development near collection hubs?

Dr. Leo Howden: Our model is built on local benefit and resilience. We collaborate with councils, universities, and local businesses. Once launched, we aim to create training pathways in green chemistry, automation, and plant operations. Each hub aims to employ local talent, support SME recyclers, and visibly demonstrate that circular industry can be both high-tech and community-rooted.

MT: Looking ahead, what does short-term and medium-term success look like in capacity deployed, geographic footprint, and the mix of owned versus partnered assets?

Dr. Leo Howden: By 2029, we will have our first commercial plant deployed, recycling thousands of tonnes of e-waste. More importantly, it means DES ionometallurgy is recognized as a mainstream, low-carbon route for metals recovery—proving sustainability and profitability can scale together. By 2032, success means multiple regional plants operating on three continents, processing tens of thousands of tonnes of e-waste and secondary feedstocks annually, with a balanced portfolio of owned flagship hubs and partner-operated sites.

MT: Dr. Howden, thank you for a candid, technically grounded conversation. Your clarity on scaling priorities, solvent stewardship, and data-driven commercial structures offers a practical roadmap for how DES ionometallurgy can integrate into real-world supply chains. We look forward to tracking Teesside’s continuous run, third-party technoeconomic analysis (TEA) / LCA reviews, and the first commercial deployments.