Support CleanTechnica’s work through a Substack subscription or on Stripe.

When I wrote recently about the rise of DC power, from long HVDC transmission lines to the direct current loads inside our laptops and EVs, someone pointed me toward what they described as a third type of electricity. They called it fault-managed power, or FMP, and said it combined the safety of AC with the efficiency of DC. That sounded intriguing, but I was skeptical. Without being a power engineer, I’ve spent a lot of time on the physics and engineering of AC and DC, and know that they are not interchangeable.

The first step in answering that question is to look at what AC and DC each do best. Alternating current remains the backbone of distribution and legacy transmission grids because it is easy to transform and distribute over long distances at varying voltages. Direct current, by contrast, is taking over at both extremes of scale. HVDC interconnectors move thousands of megawatts with lower losses than AC so it’s increasingly the preferred choice for longer-distance transmission and especially underwater or underground runs, while every digital device, solar panel, and EV battery runs internally on DC. It is no surprise that designers are searching for new ways to make the handoff between these worlds more efficient.

Fault-managed power began as an American invention aimed at making high-voltage power delivery as safe and controllable as data networking. The earliest commercial systems were developed by VoltServer, a Rhode Island firm that in the 2010s pioneered the idea of “packetized power,” sending DC energy in short monitored pulses that could shut off instantly if a cable was damaged or touched. That concept proved reliable enough to be written into the 2023 National Electrical Code as Class 4 Fault-Managed Power Systems, creating the first formal standard for active fault-limiting circuits. Once the NEC recognized it, major North American manufacturers such as Panduit, Belden, and Cence Power entered the market, and Canada began adopting similar provisions. European and Asian suppliers have started promoting compatible systems, often referencing the American UL 1400-1 and 1400-2 standards, but the U.S. remains the center of early deployment and product development.

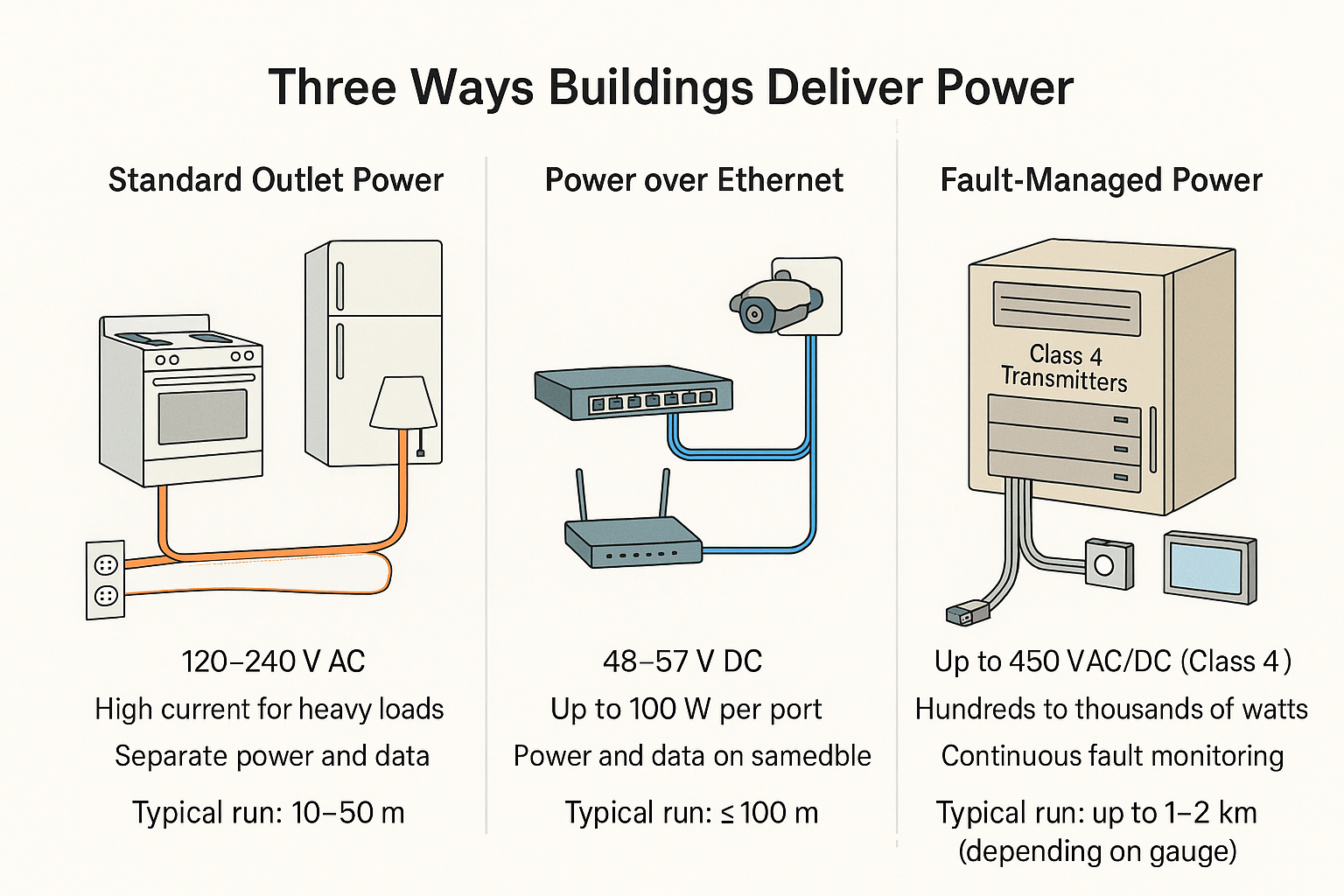

Fault-managed power can be thought of as an evolution of power over Ethernet. PoE is a standard that lets both electricity and data travel through the same standard network cable. Instead of plugging every small device into a wall outlet, a PoE-enabled switch or injector sends low-voltage DC power along the Ethernet line to anything that needs it, such as Wi-Fi routers, security cameras, access-control readers, or LED panels. Its main advantages are simplicity and safety: one cable instead of two, no need for local power adapters, and automatic shutdown if the device is disconnected or shorted. It also allows centralized control, so IT staff can reboot or monitor devices remotely. The main limitations are power and distance. Even the latest PoE standard tops out at about 100 W and runs reliably only up to around 100 m, which makes it ideal for networking and sensor equipment but unsuitable for larger mechanical or lighting loads that need more current or longer cable runs.

Fault-managed power does not rewrite the physics of electricity. It is still AC or DC on the wire, although the wire changes. Class 4 cables look broadly similar to Ethernet cables but tend to be slightly thicker and stiffer. Both use multi-conductor twisted pairs, but Class 4 cables have heavier insulation and wider conductor spacing to safely handle higher voltages and fault energy. Class 4 cables use slightly thicker copper wires inside than Ethernet cables do. The wires in a typical Ethernet cable are about the width of a paperclip wire, while those in a Class 4 cable are closer to the thickness of a pencil lead. That extra copper helps them carry more power safely over longer distances, even though it makes the cable a bit bulkier and less bendable. They remain reasonably flexible and can still be pulled and dressed like structured cabling, but they don’t bend as tightly or pack as densely in trays. Installers describe them as feeling like a “sturdy Ethernet cable” rather than something rigid like conduit wiring. In short, Class 4 cables are bulkier but still manageable with standard low-voltage installation techniques.

The key innovation sits in how the system monitors and controls the currents. Fault-managed power checks the flow of electricity by using smart electronics in the transmitter that constantly measure both voltage and current on every cable pair. Instead of sending a continuous stream of power like a normal circuit, it sends it in tiny, rapid pulses—often thousands of times per second—and watches how the line behaves after each one.

If the signal coming back from the cable looks normal, the transmitter keeps sending those pulses so that to the connected device, it feels like steady power. But if the return pattern suddenly changes—because the line was cut, shorted, or touched by something that alters resistance or capacitance—the transmitter detects the fault and stops sending energy almost instantly. Once the line’s readings return to normal, it restarts automatically.

In simple terms, it’s like a person gently tapping a surface they are walking on with a cane over and over to make sure it’s still solid. The moment the sound or feel changes, they stop. FMP does the same thing electrically, using constant micro-measurements to confirm the circuit is healthy before allowing full power to flow. That allows higher voltages and longer runs while staying safe enough to touch.

The result looks like power over Ethernet scaled up for somewhat more serious work at longer distances, with less material. A single cable can carry up to a few hundred volts and hundreds or even thousands of watts, with active fault detection that reacts in milliseconds. In practice, it means one rack-mounted transmitter can feed many remote devices through lightweight, listed cabling. Each receiver converts that managed AC or DC feed into what its load requires. If a cable is damaged, the transmitter senses the change and stops power immediately. Once the fault clears, it restores service automatically. It is still electricity, but with a nervous system.

FMP cables don’t need to be in conduit because the safety protection is built into the power electronics, not the wiring method. In a normal high-voltage circuit, conduit and heavy insulation protect people and property from electrical faults. FMP systems achieve that same safety by continuously monitoring the current and voltage on every cable pair. If the cable is damaged, shorted, or touched, the transmitter senses the change almost instantly and cuts off power before dangerous current can flow.

Because of that active protection, the circuit never has enough uncontrolled energy to start a fire or deliver a shock, even if the cable is exposed. The NEC recognizes this by allowing Class 4 cables to be installed like low-voltage data cabling—clipped, bundled, or run in trays—without needing metal conduit. The cables themselves are also listed under UL 1400-2, with insulation and construction rated for the system’s maximum voltage. In short, FMP replaces physical containment with electronic containment, using continuous fault detection to make open-air installation safe.

That architecture fits the growing complexity of modern buildings. Thousands of devices now need both electricity and data: LED drivers, sensors, cameras, Wi-Fi points, HVAC controls, and access systems. Each requires only modest power but must be monitored and networked. FMP allows both power and data to travel in the same structured cable plant, managed centrally like an IT network. Installation is faster because there is less conduit, smaller wire, and no need for hundreds of local outlets for that class of devices. Maintenance is easier because every endpoint reports its status back to the controller.

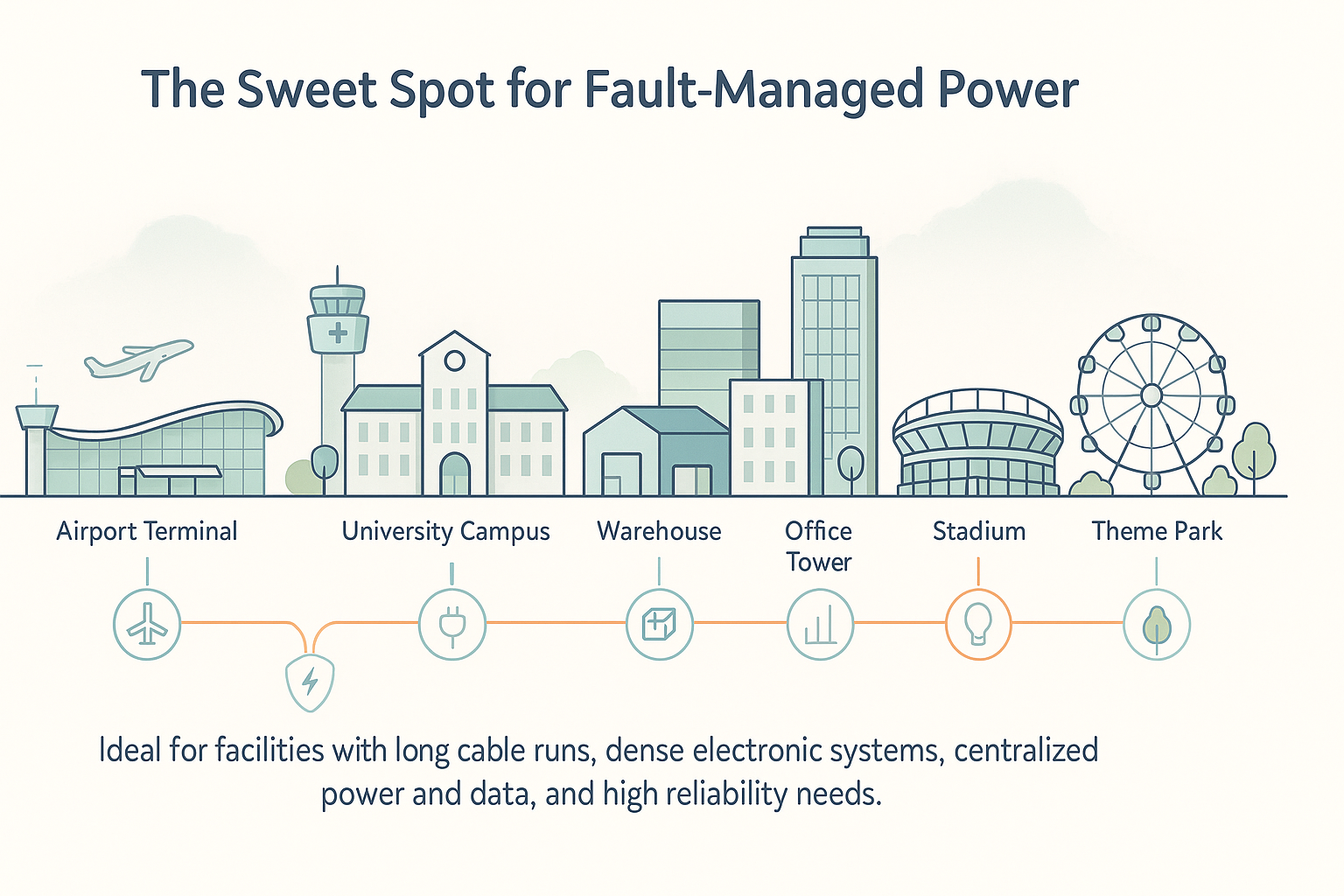

The economics are strongest in large commercial and institutional projects. A hospital, airport, or office tower can replace hundreds of branch circuits and distributed power supplies with centralized racks feeding Class 4 cables. The cost of transmitters and receivers is offset by savings in copper, conduit, and labor. Studies and case projects show reductions of 20% to 40% in installation cost and large savings in ongoing maintenance. New construction is the sweet spot because the entire distribution and control system can be designed together. Retrofitting it into finished buildings is harder since the pathways and spaces for cabling need to be planned in from the start. Residential buildings and small offices rarely have the device density to justify it.

There are clear limits. Each circuit can carry only so much power, and the code restricts FMP to about 450 V AC or DC peak. It is not going to run a stove, dryer, or heat pump. Those devices pull several kilowatts each, far above the comfortable range of fault-managed links. FMP is the nervous system of a building, not the muscle. Wall outlets and traditional branch circuits will remain the workhorses for any load that requires significant current. In the same way that HVDC did not replace the AC grid but added a new layer to it, FMP will complement existing wiring rather than remove it.

Reliability is a less obvious but real reason to consider it. Wireless lighting and sensor networks look simple on paper but fail in practice when thousands of people arrive carrying Bluetooth and Wi-Fi devices. Interference and congestion can cripple mesh networks. Wired digital power sidesteps that entirely. Every endpoint has a deterministic connection and a guaranteed response time. In a stadium, airport, or casino, where downtime is unacceptable, running copper beats relying on crowded airwaves. The same argument applies to security systems, wayfinding, and emergency lighting that must work no matter how many phones are nearby.

I’m personally aware of a situation where a mesh network solution for lights which worked brilliantly for office buildings and similar facilities failed hard in a major entertainment venue. The firm deploying the lighting solution applied it where it didn’t make sense according to clear literature on its failure modes which they didn’t bother to consider. Their successes in small scale solutions led them to sell it to a venue that had events with 20,000 attendees.

What worked fine for real time control of stadium lighting when there was no audience failed completely when an audience showed up with Bluetooth enabled smart phones and other devices, all of which started interacting with the lights, flooding the built in router queues with very simple messages. Commands for lighting changes eventually worked, but often more than ten minutes after they were issued. Effectively, mesh networks don’t work well in places with high volumes of people because the people’s devices mount an unintentional distributed denial of service attack. As soon as the firm’s owner described what had happened, even though they still didn’t know why, it was obvious to me, and while assessing FMP I found a few case studies and extensive literature on this.

For high-wattage lighting such as flood lamps or stage fixtures, FMP does not make economic sense for the power side. Those luminaires often draw one or two kilowatts each and sit in harsh outdoor environments that favor traditional 277 or 480 V AC circuits. A practical approach is to run the control gear, sensors, and lower-power lighting on FMP while feeding the heavy fixtures with normal mains. The FMP system can provide both data and low-voltage power to the controllers that in turn drive the large lights through DALI (Digital Addressable Lighting Interface) or DMX (Digital Multiplex) lines, common in commercial and entertainment lighting solutions respectively. This hybrid keeps the control layer smart and protected while leaving the brawn to the conventional system.

Many of the same venues where fault-managed power makes sense—stadiums, airports, campuses, and large commercial complexes—are also adding solar generation and on-site battery storage. Those systems bring their own layer of power electronics, sensors, and communications equipment spread across large areas. FMP can support that ecosystem by powering and networking the monitoring and control hardware that ties solar and storage into the building’s energy management system. It is not meant to carry the bulk power from panels or batteries, but it can deliver reliable, fault-protected electricity and data to the devices that measure, coordinate, and optimize them, turning a solar-equipped facility into a more unified, intelligent electrical network.

The technology has proven itself in projects like large warehouses, resorts, and corporate campuses. Installers report fewer materials, faster schedules, and simpler maintenance. The benefits scale with the number of powered devices and the length of the runs. For small buildings or homes, the advantages vanish quickly. For airports, hospitals, or entertainment complexes, they can be decisive.

Looking at the broader current war, FMP is not a rival to AC or DC but an addition to both. The world is moving toward a spectrum of electrical systems: HVDC for continental backbones, medium-voltage DC for industrial plants, FMP and PoE for intelligent buildings, and traditional mains for heavy plug loads. Each does what it is good at. There will still be standard outlets in every room, breakers in every panel, and service drops on every street. What is changing is the layer of smart, managed, and safe power running beside them.

The remaining questions are about adoption and integration. Codes and inspectors need to catch up, and trades must learn a new class of wiring that sits somewhere between electrical and IT work. The first generation of transmitters and receivers are still relatively expensive. Over time, as more vendors enter the market and more jurisdictions adopt the 2023 code, prices will fall. Future systems may tie directly into DC microgrids from rooftop solar or storage, eliminating a conversion step entirely. Whether that happens in five years or twenty, the direction is clear.

Power delivery is becoming intelligent. After a century of passive wiring, we are starting to see circuits that think, respond, and protect. FMP is part of that transition, linking the digital logic of data networks with the physical flow of electricity. It will not replace AC or DC, but it will make both safer and more efficient in the places where people live and work.

Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy