After assessing entries for the Mining Beacon Breakthrough Innovation Award against four criteria of meaningful change, uniqueness, scalability and measurable benefits in cost reduction, productivity and sustainability, the judges have announced three finalists: NatureIQ by CSIRO, Ultra vSense by MOVUS and ShovelMetrics™ Gen 3 by Weir MOTION METRICS™.

The awards, available to exhibitors at next week’s IMARC 2025 event, in Sydney, were judged by Rob Adamson (Executive Chair, RFC Ambrian), Andrew Scott FAusIMM (Autonomous Working Group Steering Committee, Global Mining Guidelines) andCaoilin Chestnutt (Non-Executive Chair, Pacgold).

Richard Roberts, Editorial Director at Beacon Events, said as soon as the nominations were open for the awards the strength of the submissions was immediately clear.

“From digital platforms to smart sensors and heavy equipment, exhibitors brought forward a remarkable array of products and solutions,” he said. “Many offered real improvements, but the purpose of this award is to celebrate a genuine breakthrough, something that has the potential to deliver step changes for the industry.”

CSIRO – NatureIQ

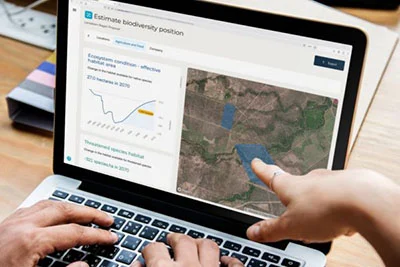

NatureIQ addresses a need that has been growing steadily across the sector: understanding the impact on biodiversity, making reliable nature-related financial disclosures and planning for effective rehabilitation. Until now, this has often meant months of scientific modelling, external consultancy work and a significant lag before insights could be used in decision making, Roberts says. “CSIRO’s platform changes that. It enables companies to track ecosystem change at fine scales, run predictive models and evaluate rehabilitation options in minutes. It is science distilled into a tool that is accessible to decision makers, not just specialists. Early feedback has been highly positive, with Heidelberg Materials describing its “ease of use”. Development has been collaborative, with mining, forestry, infrastructure and finance partners feeding into its design.”

Although still in its launch phase, NatureIQ looks set to become a critical platform for ESG reporting, rehabilitation planning and investment decisions, according to Roberts. “For me, this represents a true step forward: it makes biodiversity data as central to mining decisions as production or cost data, and that is transformative.”

MOVUS – Ultra vSense

Condition monitoring has long been a focus in mining, but solutions have often been fragmented with multiple sensors, significant cabling and high costs, Roberts says. MOVUS has consolidated vibration, temperature and RPM into one rugged device. The result is a sensor that is simpler to deploy, more cost effective and better suited to mining’s toughest operating environments, he added. “Ultra vSense replaces three sensors and a tachometer, cutting hardware costs by up to 40%. Beyond cost savings, it enables more accurate monitoring of critical assets such as conveyors, crushers and thickeners where failures can be extremely expensive. With its AI-enabled diagnostics and real-time cloud analysis, it turns raw signals into actionable insights quickly without the need for complex infrastructure.”

The recent merger with Infinite Uptime strengthens MOVUS’s market reach and technical base, according to Roberts. Together, the two companies have the potential to accelerate adoption across multiple regions and sectors. The uniqueness of the technology and its clear commercial pathway make Ultra vSense one of the strongest contenders for this award.

Weir MOTION METRICS – ShovelMetrics Gen 3

One of the most persistent challenges in open-pit mining has been shovel payload monitoring. Traditional methods rely on truck scales or post-load analysis, which provide feedback too late to optimise loading in real time, Roberts claims. Weir MOTION METRICS has taken a different approach by shifting intelligence directly onto the shovel. ShovelMetrics Gen 3 uses rugged sensors to provide operators with precise, in-cab feedback. Every pass can be optimised for truck fill, cycle time and energy use. The benefits are broad: more consistent productivity, reduced operating costs and lower emissions through efficient loading. In practice, this is the kind of tool that improves operator confidence and paves the way for full automation in the future.

“Although its introduction in July 2025 means it is still early in its commercial journey, the potential impact is significant,” Roberts says. “If the system proves reliable across different shovels and ore types, it could redefine loading practices across the industry. That possibility alone makes it deserving of a finalist place.”

Other submissions

While only three could be shortlisted, several other submissions were recognised:

- Aquip’s MAUS Stixx Pro embedded autonomous fire suppression directly into electrical enclosures. This compact, residue-free solution will be increasingly important as mining electrifies.

- RapidGraphite, a Curtin University spin-out, presented a catalytic process to convert biochar into synthetic graphite for batteries. Early results point to lower emissions and costs, addressing one of the most pressing resource supply challenges.

- Epiroc’s Minetruck MT66 S eDrive introduced a diesel-electric drivetrain for underground haulage, delivering higher efficiency and positioning itself as a future-ready platform for zero-emission technologies.

- Hexagon’s Operator Alertness System 7.5 integrated fatigue monitoring with collision avoidance, giving operators and safety teams a powerful combined view of risk.

- Novecom’s SentineX AiCoustics applied AI to real-time noise classification, distinguishing between drilling, blasting and equipment noise to improve compliance and operational response.

- Veracio’s HyperXRF combined hyperspectral imaging with XRF in a LiDAR-guided platform, producing accurate mineralogical and geochemical datasets in under 48 hours.

The winner will be announced at the IMARC Gala Dinner on October 23 at ICC Sydney.