Support CleanTechnica’s work through a Substack subscription or on Stripe.

International shipping contributes to CO2, NO2, and SO2 emissions. Pollution from Heavy Fuel Oil (HFO), colloquially termed bunker fuel, has long been considered a problem. Heavy Fuel Oil has high sulfur content, and the global shipping industry produces 12% and 13% respectively of global SO2 and NO2 emissions, contributing a disproportionate amount to lung cancer and cardiovascular disease. Bunker fuel is refined from crude oil, and comes out after the process removes lighter fuels like gasoline and kerosene. Bunker fuel and tar are the lowest grade refining remnants. HFO is thick like syrup and loaded with impurities such as sulfur. This low-grade fuel cannot be burned on land because it is too polluting, but on the high seas, away from land, it has been tolerated, until now. By 2050, maritime CO2 emissions are projected to rise to 17% of global emissions. Due to mounting pressure, the International Maritime Organization (IMO) has taken regulatory action to lower GHG, SO2, and CO2 emissions. Pressure is mounting to find and deploy solutions to lower emissions. In response, battery electric ships are in operation in rivers and near shore and are now being considered for longer distances.

In a previous article, I showed that electric container ships of 7,000 TEU capacity powered by modern batteries can be practical, carrying useful amounts of cargo, up to a range of about 5,000 km.

“An Atlantic-route 7,000 TEU container ship could traverse 3,166 km, using 2,600 MWh (3,166/12,500 × 10,280 MWh). At 3 MW per TEU, it would require 867 TEU out of 7,000, or 12.4% of cargo. The longest leg of the Pacific route would entail roughly 3,070 MWh (3,730/12,500 × 10,280 MWh), or 1,020 TEU, 14.5% of the total TEU.”

Studies have come to similar range and cargo capacity conclusions, adding, “We show that at battery prices of US$100/ kWh, the electrification of intraregional trade routes of less than 1,500 km is economical, with minimal impact to ship carrying capacity. Including the environmental costs increases the economical range to 5,000 km. If batteries achieve a US$50/ kWh price point, the economical range nearly doubles. We describe a pathway for the battery electrification of containerships within this decade that electrifies over 40% of global containership traffic, reduces CO2 emissions by 14% for US-based vessels, and mitigates the health impacts of air pollution on coastal communities.”

The transition to river-going and near-shore electric shipping is underway, in Europe, China, Brazil, and Canada. Battery electric ships (BES) are now plying waterways across the globe. Michael Barnard has reported the increasing use of electric ferries and reports that, “This transition, which seemed speculative just a decade ago, has moved swiftly from niche experiments in sustainability to mainstream procurement decisions, and the industry is now firmly on a trajectory toward large-scale electrification.”

While earlier studies failed to keep up with rapidly falling battery prices, later papers revealed that tugboats, ferries, river barges, and other short- and medium-distance electric ship operations are now feasible, with battery prices in the neighborhood of $51/kW reported in China.

The COSCO Green River 1 container ship shows the way toward ever longer-distance container ship operation with the flexibility of standardized swappable TEU energy storage containers. In a recent article, Michael Barnard highlighted the use of renewable-powered battery swaps. He stated, “There are really obvious solutions to big problems. One of those solutions is putting batteries in shipping containers and winching them on and off ships to power electric drivetrains. Recharge the containers on land in transshipment ports and winch them onto the next ship or train that needs one.”

Studies recognize that global shipping concentration points such as the Suez and Panama Canals, and Straits, and frequently used ports represent a clear case for maritime electrification combining high rates of shipping and available power sources.

The need for further electrification of sea transport to more distant ports exists. Solutions are needed for cargo transport across oceanic distances. While at first it appears that long-distance cross ocean electric shipping is beyond present capabilities, with many long routes across open water, a second look shows many routes are not far from land and existing available harbors.

North Atlantic, Europe to Asia Routes Within Range

With 5,000 km of range, the north Atlantic crossing does not require in-transit recharging. Existing routes from Europe to St. Johns Newfoundland or Halifax Nova Scotia are less than 5,000 km. Great circle routes, the shortest distances between points on the globe, can look curved on mercator projection maps. The great circle distance from Cork, Ireland, to Halifax, Nova Scotia, is about 4,000 km. The great circle distance from Cork to St. Johns, Newfoundland, is even shorter, 3,166 km. From the Azores to St. Johns is 2,233 km.

Much maritime traffic serves multiple ports, resulting in routes hugging coastlines before heading across open water. For instance, much of the the Suez route from Europe to Asia passes near shore. The longest Europe/Asia open water trip from India to Southeast Asia is 3,500 km. Much of existing Europe/Asia traffic could be served by electric ships. There is the potential to use less onboard energy storage for much of that route, and add necessary additional energy storage containers only on the longest open water sections.

Pacific Cargo Ship Traffic

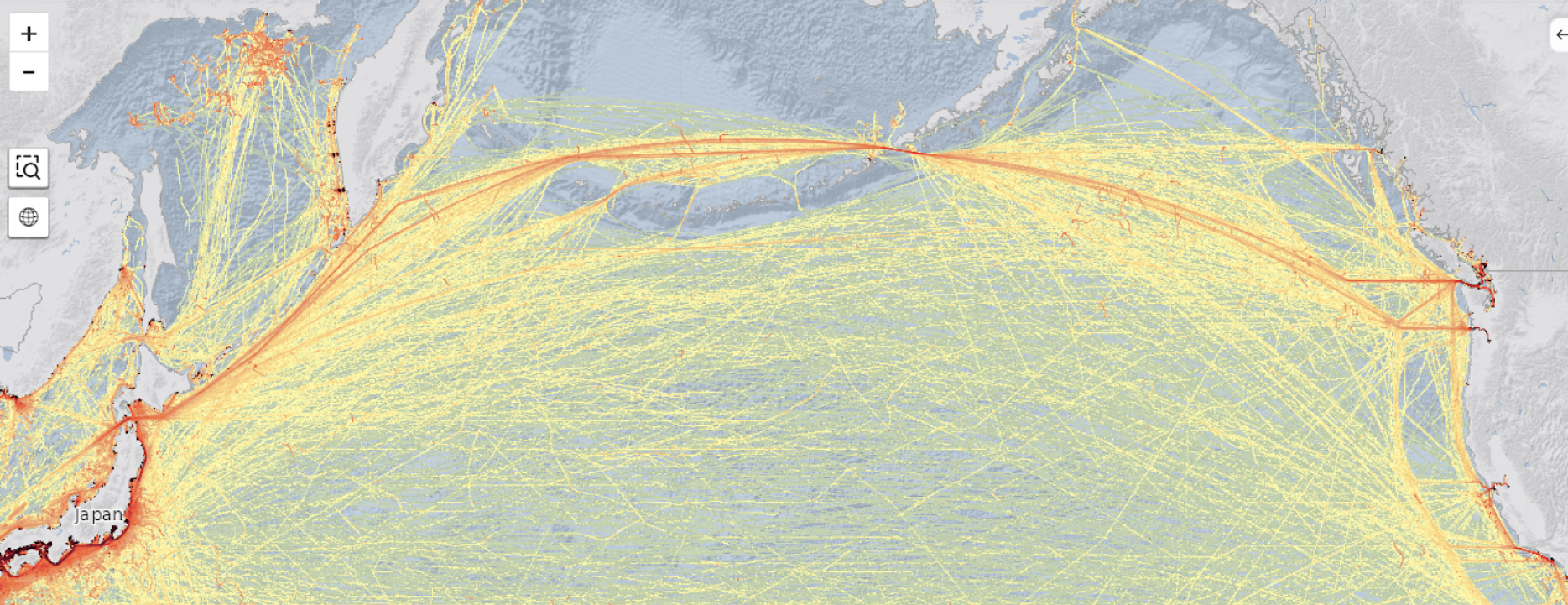

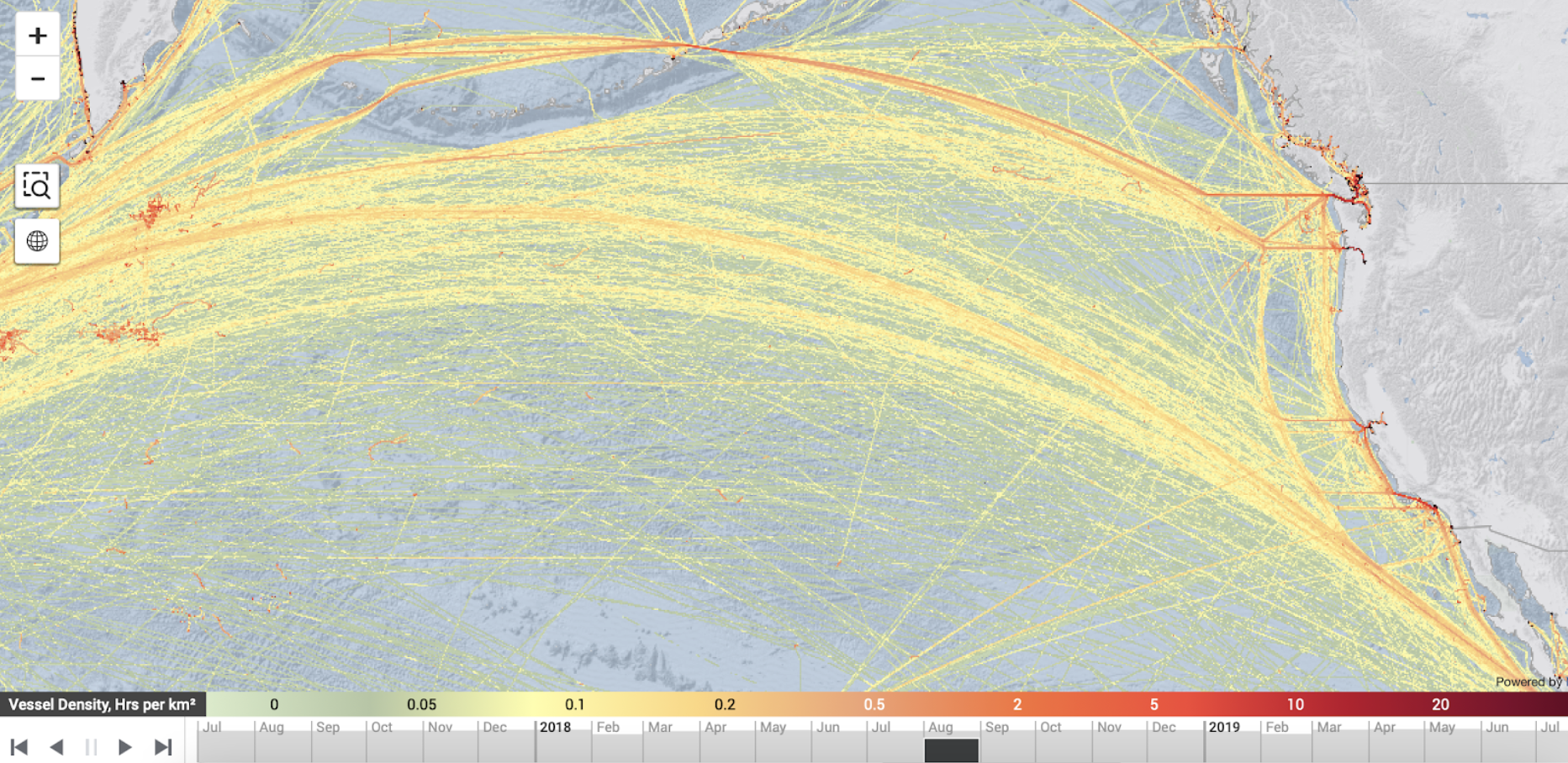

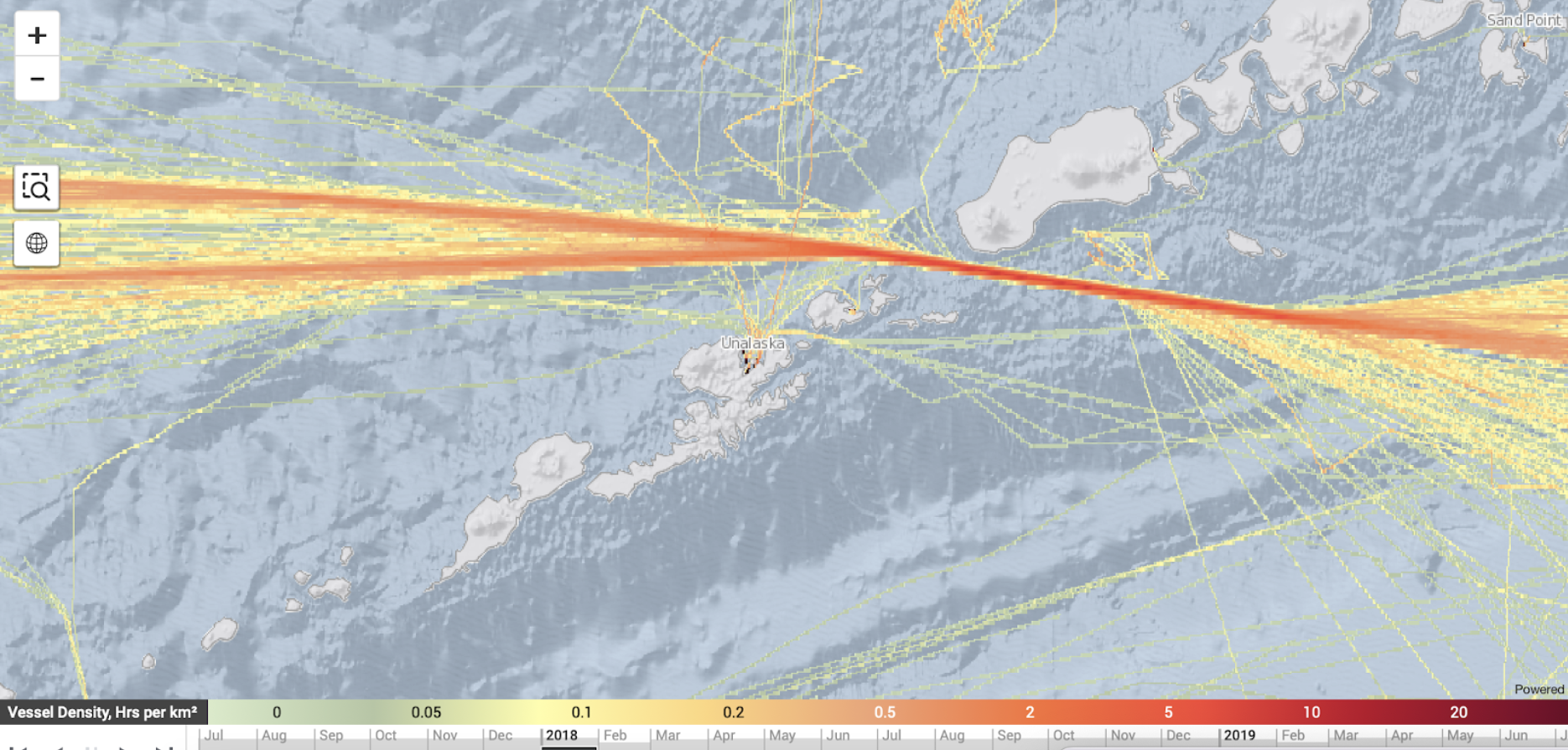

Cross-Pacific transport from North America to Japan is more challenging, with a nonstop distance of 7,000 km from Seattle to Japan, requiring energy transfer at ports en route. Existing traffic from San Francisco north travels steadily year round through the Aleutians, passing near Dutch Harbor in the Aleutians, shown in Figure 4, on routes to Korea, Japan, and China. This is the shortest distance from Seattle to Japan. The longest open water Pacific distance from Dutch Harbor to the Port of Hakodate in Hokkaido, Japan, is about 4,000 km. This trip may be navigated by ships with 5,000 km of range by recharging or swapping at Dutch Harbor. The distance from Seattle, Washington, to Dutch Harbor is 3,134 km. Figure 2 shows cross-Pacific cargo traffic density on 1-18. Traffic from the Port of LA splits in July and August, shown in Figure 3, with part heading north along the coast toward the Aleutians and part heading further south. The rest of the year it predominantly follows the coast up to Seattle and goes the north route past Dutch Harbor.

Suitable Pacific Ports En Route

Large post-Panamax container ships routinely anchor at Dutch Harbor Alaska. The location is an ideal midpoint across the Pacific from North America to Asia. The containership, CGA CGM Swordfish, a large 5098 TEU container ship, is expected to arrive July 9, at 23:00 and another, White Shark, at about the same time. While container ship capacity at Kodiak and Dutch Harbor is not yet large, the port facilities could be expanded with increased demand. Matson has container facilities at Tacoma, Washington, and at Anchorage, Kodiak, and Dutch Harbor, Alaska. Dutch Harbor is located on Unalaska Island, an island in the eastern Aleutian Islands chain, 80 miles long and 35 miles wide — 1,000 square miles. Kodiak Island is a much larger island off the coast of Alaska, closer to Anchorage. There are other ports near Dutch Harbor at locations along the peninsula, like Cold Bay. Other stops, such as Prince Rupert, Canada, could be utilized to reduce charging needs.

Renewable Power Resources

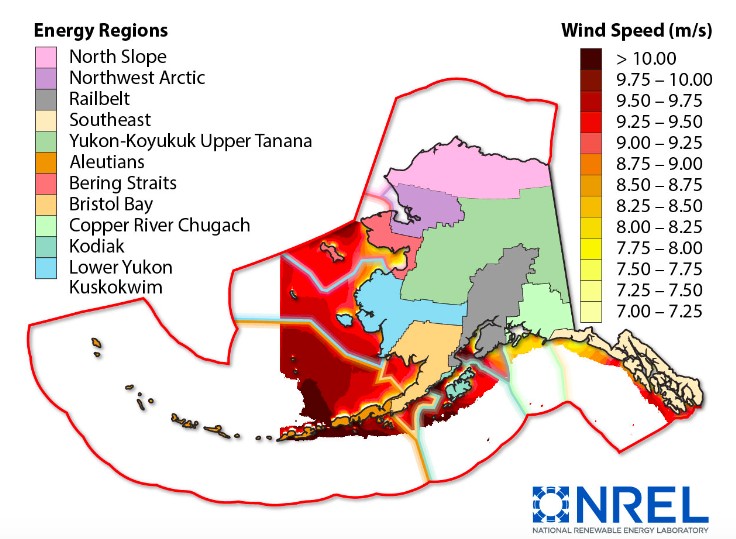

Wind resources along the Aleutian chain are excellent, with an average wind speed of about 20 mph, around 9 m/s (Figure 5). Normally, in the lower 48 states, ground wind speeds above 5 m/s are considered an adequate minimum for wind power siting. At 9 m/s rather than 5, with power proportional to velocity cubed, output is nearly 6 times larger. Modern wind turbines operate with hubs at 50 to 100 meters. Wind speeds aloft at 100 meters are generally higher and steadier. The GE Vernova 6 MW-158m wind turbine has a hub height of 96 meters. With electric ships charging batteries, storage could provide a compatible load, absorbing variable wind generation and enhancing load matching. Expanded renewable power generation used for charging electric ships could also provide power to the community and to port operations, including electric cranes and drayage equipment. Unalaska has geothermal resources. At present, Unalaska is served by diesel generation and most of the electricity consumption is commercial.

Harbors and airports are often in wind protected areas, not the best wind siting. A study of Aleutian wind resources by Tunis Wentik at the University of Alaska reported that “winds for some degree of power generation are available 77 percent of the time.” Unalaska has also identified hydro resources.

Kodiak Island went nearly 100% renewable electricity in 2015, with hydro and wind. Modern large wind turbines have been sited on Kodiak Island, where three 1.5 MW GE and three 1.6 MW GE wind turbines have been installed on land at Pillar Mountain. Unalaska could also install large wind turbines, and Unalaska has been eyeing that possibility for some time. BOEM conducted a study of offshore wind in Alaska, citing 9 m/s average wind speed.

Electric Ship Energy Requirements

About 3 GWh of energy storage is necessary for a 7,000 TEU container ship to complete a 4,000 km journey. At a rate of supply of one ship every 24 hours, an equivalent constant 125 MW is required for charging. At the average wind speed of 9 m/s, a GE Vernova 2.5 MW wind turbine is near cutout wind speed of about 10 to 11 m/s. The power output is 2.5 MW at max output. Vessels could be fully charged directly or with a combination of wind power and stored energy, depending on the configuration of available power and usage. A 125 MW equivalent would provide for 365 vessels a year if the port could operate on a daily basis. Ships could swap energy storage in port at the rate of of one every 24 hours using this configuration.

Charging Options

Various solutions exist for recharging ships transiting the Pacific. Ships can fully charge onboard batteries in 24 hours, or swap batteries in port in less time. Fully charged packs can be transported to locations for swapping. Given battery capacity required for 4,000 km range is 10% to 15% of total TEU, swapping at a port would take less time than the 67 hours required to unload an entire 10,000 TEU container ship. An average unloading time for a full container ship depends on the size of container ship and number of cranes. For a 10,000 TEU container ship with 5 cranes operating simultaneously, containers can be unloaded every 2 minutes, or 30 per hour. With 5 cranes, that gives 150 per hour. For a 10,000 TEU load, the time would be 67 hours, or about 3 days. Swapping the full complement of 1,000 energy storage containers in the 7,000 TEU example, would take about 14 hours, just 21% of full loading time. However, container ships are rarely fully emptied at one port. To reduce times, some cranes can lift two or more TEU. Ships often unload less than full load at multiple ports, reducing harbor time. Energy storage may not need to be fully swapped at a port if batteries are not fully discharged.

It is also possible to transport fully charged packs to the midpoint terminal along the Aleutian chain from more developed areas like Anchorage using a battery shipping vessel like a refueling ship. A large container ship is capable of transporting as many of six container ship energy storage packs to the charging midpoints. Renewable power could be used to charge packs at nearby locations like Cold Bay, False, Pass, and Kodiak Island, and transport to Dutch Harbor.

Greater Shipping Capacity With More Stops En Route

Only the depleted portion of battery capacity need be swapped or charged. For example, a ship of 5,000 km range traveling west from Seattle would use a fraction of its total battery capacity to travel to Dutch Harbor, a 2,000 km distance. About 60% of charge would remain. Only 40% of charge would be needed at Dutch Harbor to continue west, reducing charging requirements at Dutch Harbor. This effect could be extended and enhanced by charging at other close ports, like Prince Rupert or Kodiak.

The effect works in both directions. Eastbound ships could stop at Dutch Harbor, and recharge only enough to stop and recharge at the next port, say Kodiak, only about 1,330 km away. Ships arriving at Dutch Harbor would then need less charge capacity, about 27% of total capacity, or 675 kWh. That would reduce the power required to recharge ships at Dutch Harbor. In this example, in the given wind power scenario of 125 MW equivalent, the number of vessels serviced daily at Dutch Harbor could increase by 3.7×, a theoretical annual capacity of 1,352 ships.

Partial Charge, Discharge, Multiple Packs

When adding storage en route, it is expedient that energy storage units are stacked vertically in a series connected configuration creating multiple full voltage packs. This way packs may be added or removed according to trip needs. This aids vessel propulsion flexibility on shorter distance routes. Separate energy storage packs also allow charging from multiple chargers in parallel, reducing power per charger. When packs are added, all packs may no longer have the same terminal voltage. There are at least two means of dealing with this.

One method drives several propellers, each with its own battery pack. Each propeller output can be served to match rpm and thrust. In another preferred method, electric propulsion employs conditioning electronics between battery and motor. In this manner, motor voltages and current and power output can be made independent of multiple battery pack voltages. The power output of several battery energy storage devices of different charge level can be combined into a single output using multiple input, single output (MISO) power conditioning, and single or multiple propeller operation can be employed. Such methods allow a high degree of flexibility. Stacks of these cells can be placed near the center of the ship. Placement starting low in the hull near the center of gravity helps with stability.

Energy Storage Standardization

Energy storage standardization is easier with container ships than land transport. Container mechanical dimensions and fastening already have a high degree of standardization. This solves the biggest problem with swap standardization, storage physical dimension and mounting characteristics. The standard mechanisms for moving and securing 20-foot-equivalent (TEU) containers are well established at ports globally. The remaining standardization involves connectors, and most importantly, charger communication standards. A standard charging connector and communication protocol similar to those for DCFC and J1772 can be expanded to larger formats. It is possible to have a few different connector standards, just as with electric cars, but fewer is better.

Electrical characteristics, battery chemistries, voltages, and currents can be easily accommodated by an intelligent EVSE with battery storage to EVSE communication. The battery BMS supplies information for the required voltage and current for the storage device. EVSE chargers respond to the battery energy storage requests appropriately at voltage and currents they require. A degree of battery storage electrical variation, like the 300V to 900V operation of EVSE, as well as myriad chemistries such as NMC, NCA, and LFP, are thus easily accommodated with the methods commonly used for EV charging. The interface requires communication between charger and battery energy storage devices with standard universal communication protocols, at hardware and software levels.

Charging Standards for Different Ship Types

Ships that travel globally at varied routes need good standardization. Ships that travel short, fixed, round-trip routes in fleets, like ferry boats, have different requirements than ships traveling varied routes. Vehicles operated in fleets can use their own standard equipment. Several ferry boat charging methods, reported here and here, have appeared in waters around Europe. Early technology adoption often results in exploration of a variety of techniques and standards. Early experience teaches which applications require strong standardization and which can use a more flexible approach and guides selection of best practice and technology.

Conclusion

Pressure is mounting globally to lower maritime internal combustion emissions. Electric ships offer a lower emissions alternative. Ever lower battery prices and rugged storage have initiated the onset of the first electric ship use. Electric ships have started with ferry boats and tugs, and container ships exist today for riverine and near-shore medium- and short-range applications today. Present day battery costs enable ranges of up to 5,000 km.

Much of global shipping is riverine, and much is near shore even when traveling continent to continent, with ship traffic loading and unloading at multiple ports in transit. Only part of global shipping requires extreme range. With the use of island port renewable charging and containerized energy storage swaps, shorter journey legs can enable global electric cargo ship transit to replace ICE with ship ranges of under 5,000 km. This points the way to a means of expanding early electric shipping to longer distances and greater coverage globally.

Electric ships, like land-based transport, do not need to copy existing internal combustion modes of operation and characteristics one-for-one. Maritime electric transport has unique characteristics that require new modes of use with energy storage. Shorter distance waypoints at island ports using swappable containerized energy storage enable long-distance electric shipping and allow a high degree of operational flexibility.

Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy