Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

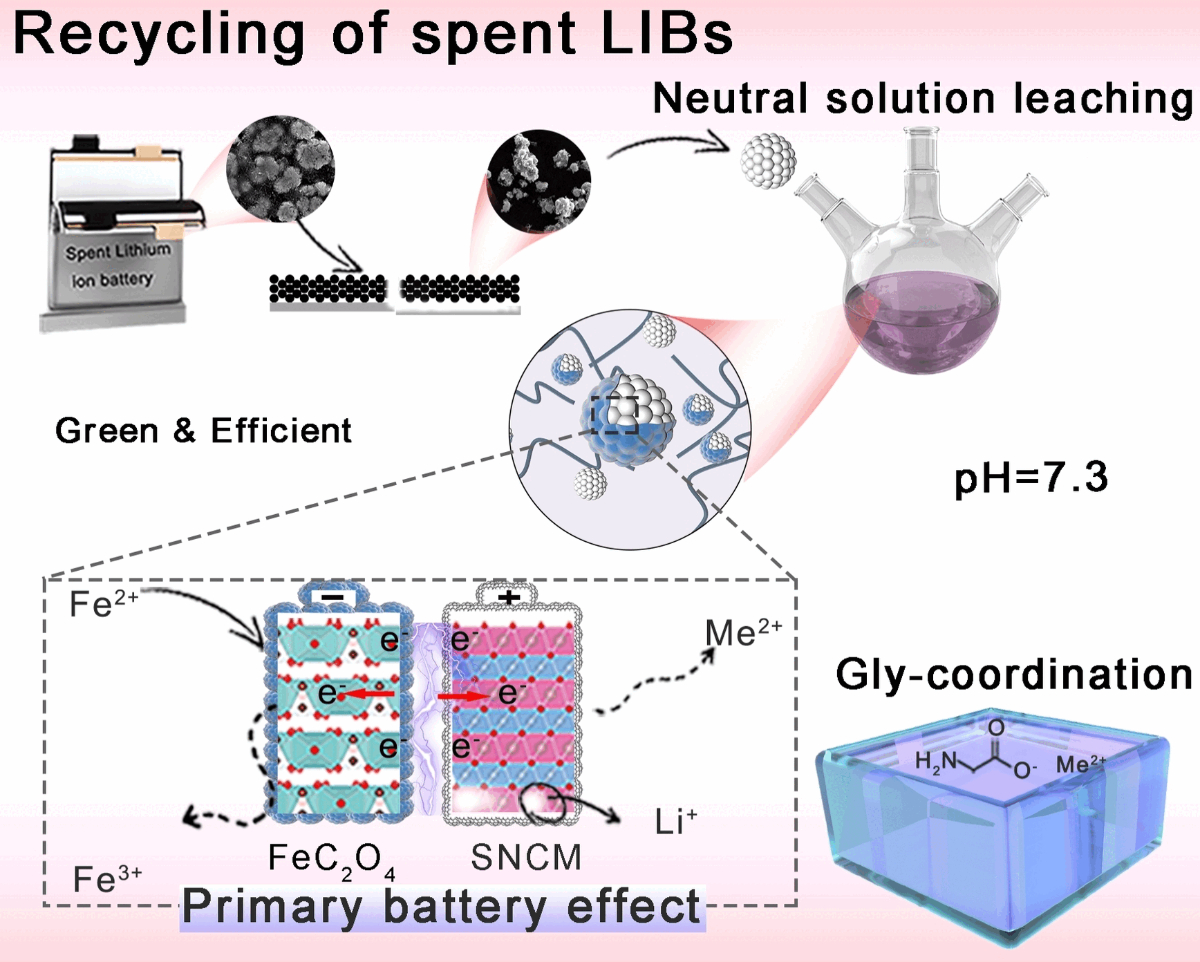

A new breakthrough in battery recycling has emerged from a team of researchers in China that has developed an eco-friendly way to recover nearly all valuable materials from depleted lithium ion batteries. The innovative process uses glycine, an amino acid, to extract 99.99% of lithium and significant percentages of nickel, cobalt, and manganese from old batteries in just 15 minutes. Unlike traditional methods, this approach avoids harsh chemicals and minimizes environmental harm, generating effluents suitable for use as fertilizer. The research was published in the Journal of the German Chemical Society on February 18, 2025.

The researchers preface their findings with this statement. “To address the overuse of strong acids and bases in the conventional hydro-metallurgy process, a delicate strategy has been proposed, which is pioneeringly applied in the neutral solution environment. Particularly, in situ primary battery effect based on the solid-solid reduction is designed and constructed, which can effectively enhance the reduction efficiency of high-valent metals by leveraging electron transfer during the neutral leaching. It can achieve ultra-fast efficiency with reduced chemical consumption and corrosive wastewater, thus providing a promising and economic pathway for the battery recycling.”

The Many Benefits Of Recycling

According to Battery News, advancements such as this one are critical to address the growing e-waste problem, which is being driven by an increasing demand for consumer electronics and electric vehicles. The global lithium-ion battery recycling market was valued at $138.62 million in 2023 and is expected to expand at a compound annual growth rate of 44.8% from 2024 to 2030. The implications extend to reducing raw material mining, lowering emissions, and paving the way for sustainable large-scale recycling operations.

The groundbreaking method, developed by researchers from Central South University, Guizhou Normal University, and the National Engineering Research Center of Advanced Energy Storage Materials, employs a unique ‘battery effect’ mechanism. The process achieves remarkable recovery rates: 99.99% of lithium, 96.8% of nickel, 92.35% of cobalt, and 90.59% of manganese, all within just 15 minutes.

What sets this method apart from other battery recycling methods is its use of a neutral solution environment which eliminates the need to use the harsh chemicals typically associated with battery recycling. Dr. Xing Ou, a professor at Central South University, emphasizes that the process produces minimal harmful gases while the glycine effluent can be repurposed as fertilizer. This advancement comes at a crucial time, as a recent Stanford University study published January 31, 2025 in Nature Communications confirms that recycling lithium-ion batteries is substantially more environmentally friendly than mining new materials.

The timing of this breakthrough is particularly significant given the mounting challenges of managing e-waste from smartphones, laptops, and electric vehicles. Traditional recycling methods have often been environmentally problematic due to the byproducts and emissions associated with them. This new approach represents a significant step toward large scale, pollution-free battery recycling. The process is more environmentally conscious and proves more cost effective and energy efficient than conventional methods.

The Stanford Battery Recycling Study

In the Stanford battery recycling study mentioned above, the authors say recycling lithium-ion batteries to recover their critical metals has significantly lower environmental impacts than mining virgin metals. On a large scale, recycling could also help relieve the long term supply insecurity – physically and geopolitically – of critical battery minerals. In other words, we might not need quite so much lithium, manganese, nickel, or cobalt if we can extract them from depleted batteries and recycle them.

The study found that recycling emits less greenhouse gas pollution compared to conventional mining and refinement of battery materials and uses about one quarter of the water and energy need to mine new materials. The environmental benefits are even greater for the scrap stream, which accounted for about 90% of the recycled supply studied. The research found recycling created only 19% of the GHG emissions of mining and processing, while using only 12% of the water and 11% of the energy use.

“Recently, I was in an Uber electric vehicle. The driver asked me if EVs really are ‘good’ for the environment because he had read that maybe they aren’t. All he knew was that I was faculty at Stanford,” William Tarpeh, assistant professor of chemical engineering in the School of Engineering and the study’s senior author, said. “I told him that EVs definitely are good for the environment, and we’re now finding new ways to make them even more so. This study tells us we can design the future of battery recycling to optimize the environmental benefits. We can write the script.”

The environmental impacts of battery recycling rely heavily on the processing facility’s location and electricity source. “A battery recycling plant in regions that rely heavily on electricity generated by burning coal would see a diminished climate advantage,” said Samantha Bunke, a PhD student at Stanford and one of the study’s three lead investigators. “On the other hand, fresh water shortages in regions with cleaner electricity are a great concern. Most of the date for the study came from Redwood Materials in Nevada,which benefits from the cleaner energy mix in that state.

Transportation is also a crucial factor. In the mining and processing of cobalt, for example, 80% of the global supply is mined in the Democratic Republic of the Congo. From there, 75% of the cobalt supply for batteries travels by road, rail, and sea to China for refining. Meanwhile, most of the global supply of lithium is mined in Australia and Chile and most of that supply makes its way to China also. The equivalent process for battery recycling is collecting used batteries and scrap, which must then be transported to the recycler.

“We determined that the total transport distance for conventional mining and refining of just the active metals in a battery averages about 35,000 miles (57,000 kilometers). That’s like going around the world one and a half times,” said Michael Machala, a lead author of the study. “Our estimated total transport of used batteries from your cell phone or an EV to a hypothetical refinement facility in California was around 140 miles (225 kilometers).” This distance was based on presumed optimal locations for future refining facilities amid ample US recyclable batteries.

China, China, China

Did you notice that China figures prominently in many research reports? Why is that? Could it be that the Chinese government has promoted basic research in clean energy and clean transportation for decades while the United States has been fixated on black and brown faces crossing its borders? Solar panel and lithium-ion battery technology began in the US, but it was not that interested in pursuing either. Solyndra was a company in California that wanted to manufacture solar panels. Nearly 20 years ago, it was granted a government backed loan, but market forces — exacerbated by a lack of policy support at the federal level because Congress wouldn’t stand for it — prevented it from being profitable and it went bankrupt. Republicans hung that failure like an albatross around the neck of the Obama administration and gloated about how they were owning the libs and fighting “woke” ideas — like harvesting energy from the sun was some sort of satanic plot hatched by George Soros.

Today, China is leading in solar, in batteries, in EVs, in wind power, and in computer technology. The US is consumed by a passion for slashing Social Security, the VA, Medicare, and the school lunch program while prosecuting anyone who dares raise a voice in opposition. Researchers like the those who devised the new battery recycling technology are no longer welcome at American colleges and universities, a misguided policy that will hobble American research efforts now and in the future. America is retreating into itself and sucking its collective thumb and moaning about how unfair things are. By contrast, China is seizing the initiative in a drive to supplant the US as the leading nation in the global community. Such navel gazing by the US may be the most colossal “own goal” since “Wrong Way” Ray Reigels scored a touchdown for the other team in the 1929 Rose Bowl. Congratulations, America. You asked for it and boy, howdy, are you ever going to get it!

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy