Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Key takeaways:

- No truck stop or distribution center is unique

- Establish corporate control and management of the program

- Optimize the mix of vendors and staff for different phases of the program

The uniqueness bias is a finding of Professor Bent Flyvbjerg, global megaprojects expert and author of the 2023 business book of the year, How Big Things Get Done. It is the tendency of decision-makers, especially in large-scale projects, to overestimate the novelty or distinctiveness of their project, leading them to believe that standard benchmarks, historical data, or lessons from other projects do not apply.

And it’s the enemy of incremental charging microgrids.

Every site will claim it has unique attributes that require a custom solution. Every engineering, procurement, and construction firm will attempt to get you to engineer a solution for every site’s purportedly unique characteristics. Every microgrid component vendor will attempt to upsell you on their product. Every local politician and business development agency will try to get you to use local, or at least well connected, vendors for the microgrid in their county or municipality. They’ll all be touting the unique challenges or benefits faced.

It’s all nonsense. A big truck stop is a big truck stop and a big distribution center is a big distribution center, regardless of whether it’s in Minnesota or Louisiana. It may get a little less sunshine and more snow, but it’s the amount of space that determines how much solar can be put on the site, not the weather. It may be hot or it may be cold, but the batteries still need thermal management. It may have a more robust local utility or one that can’t keep the lights on, but trucks still need charging. It still needs battery management systems. The utilities providing power connection may be different, yet they all need the same electrical connections.

As the authors — Rish Ghatikar and Michael Barnard, experts in sustainability, transportation, and strategy — explored in their diagnosis of the challenges of truck charging, there are overlapping concerns which can heavily slow down deployment of megawatt-scale charging solutions to accelerate truck electrification, and getting derailed into non-charging value propositions is one of them. So far the actions have included incrementally adding charging capacity in standardized increments, leveraging the pricing flexibility that microgrids with solar and batteries afford for competitive advantage, finding your LEGO for modular microgrid components, and sticking to the knitting of charging, all explored in previous articles. Avoiding the all too human uniqueness bias is another key part of the strategy.

The target stakeholders for this strategy for microgrid charging operate hundreds or even low thousands of sites, or build those sites for their customers. The cookie cutter strategy outlined in other articles in this set of internally reinforcing actions call for incremental additions of highly standardized and modularized components over time, but the increments and components have to stay the same, or the benefits start to erode.

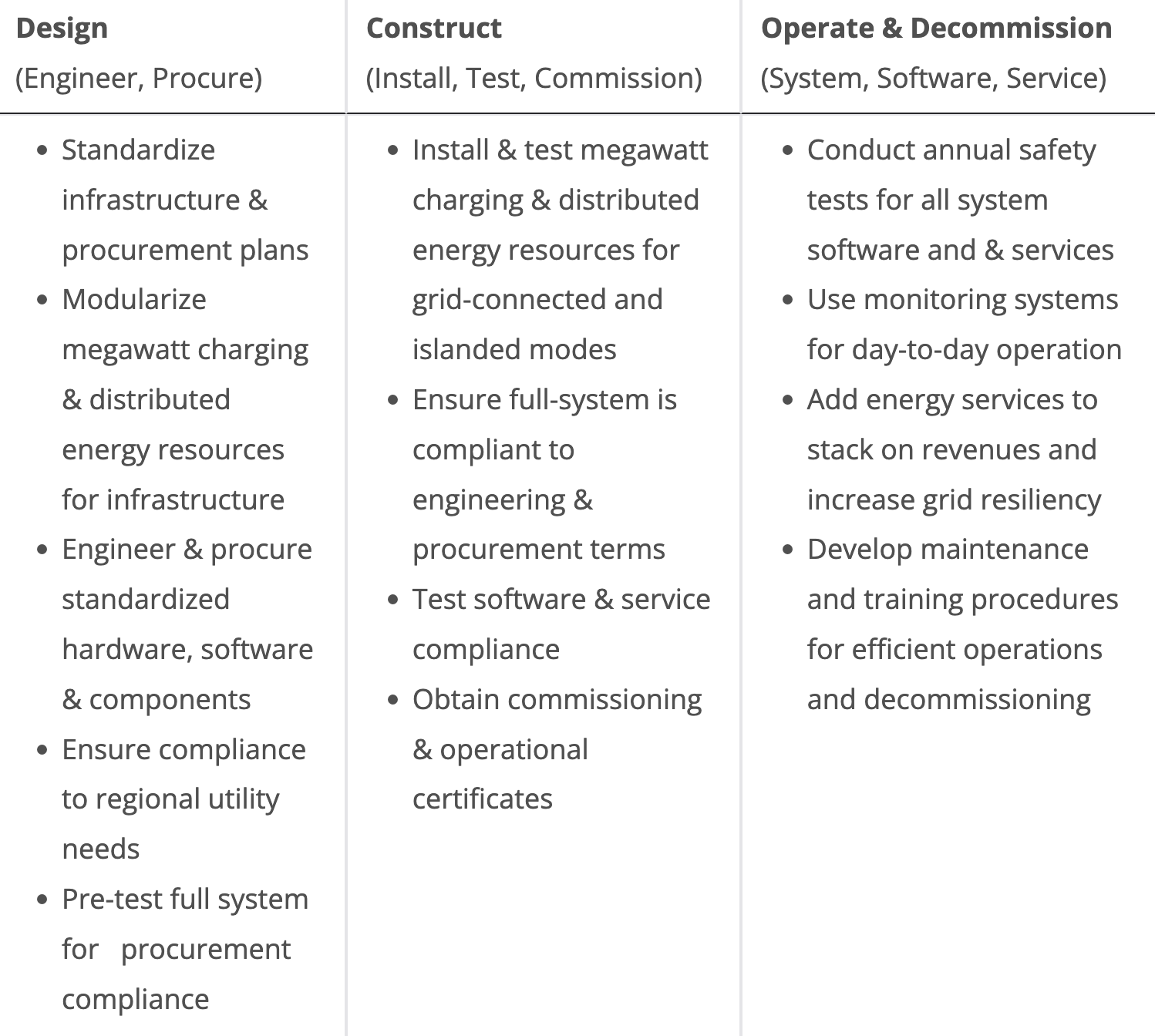

Target stakeholders must consider the replicability during the design, construction, operation, and decommissioning processes that we refer to as the microgrid charging lifecycle. The microgrid charging lifecycle is a set of interconnected processes where the lessons from one process must be incorporated into new microgrid processes for improved efficiency and economics (e.g., issues identified during construction and operation can lead to better design process).

As we consider the challenges, an initially small microgrid that grows in increments with standards-based modular components addresses many of them. It avoids significant capital costs early in the lifecycle of the microgrid charging and improves operational efficiencies during construction and operational phases. It is much easier to shepherd through often complex regulatory and policy barriers, typically avoiding them entirely. It makes interconnection and utility coordination much simpler, potentially reducing it to simple municipal electrical inspections and approvals. It specifically leans into components and communications standardization.

For optimal operations and procurement of microgrid systems and grid integration, consider standardized control strategies and communications for energy services that generate revenue — particularly for depots with more charging flexibility. Summary actions to standardize components and software at all stages of microgrid charging lifecycle are listed here.

The lifecycle approach ensures capabilities exist and avoids concerns about balancing local grids and providing resiliency and reliability services when not needed. Those capabilities can be added later as the microgrid grows, but trying to build them in initially as a good neighbor will simply bog the entire process down, defer revenue, and add complexity.

Standardization enables an installation team and local contractors to deploy the same thing over and over with no local flavors. Microgrid components can be assembled and tested in regional staging sites and shipped virtually intact for deployment. Tesla does this today with its Superchargers, assembling several of them on a poured concrete slab at the factory with all of the power connections and power management technology, and then delivering the slab by flatbed to the site for lowering onto the parking lot and connecting to the grid. That’s the model to work toward emulating.

A strategic and competitive vendor management approach with the providers of transformers, converters, battery systems, solar panels, charging systems, and the software systems which manage them will enable the best prices, the highest reliability and the best service levels. A patchwork quilt of different vendors around the United States would lead to higher overall costs and lower service levels.

Over the course of the fifteen to twenty years of transformation of all sites, millions will be spent on each site, with the total program being over a billion dollars. This is a megaproject of many individual projects and needs to be treated as such.

Between them, the authors of this strategy series have extensive experience with major programs. Ghatikar ran decarbonization programs with the US Department of Energy, including a focus on microgrids, and worked for GM in its energy division as it considered how that firm could accelerate delivery. Barnard’s work experience includes running projects delivering new computer and telecommunication upgrades to 1,400 physical locations, including five on permafrost in the far north, authoring incremental major program management methodologies, and solutioning and kicking off billion dollar technology projects on four continents.

Beyond the advice to buy How Big Things Get Done and read it, they have some key recommendations for ensuring that the uniqueness bias doesn’t dissolve the benefit case over the time scale in question.

First, establish a corporate team devoted to this. It’s not something that is going to be done off the side of anyone’s desk, it’s not something that local teams will figure out, it’s not something the corporation can put in the normal project hopper for the operations team to figure out. This is a major, potentially billion dollar plus program that is going to last a couple of decades. It needs executive leadership, visibility, and budget.

Second, centralize design authority in the corporate team. Regardless of what regional managers or technically talented site operations teams think, this is a corporate function. If there are talented site operations teams that have been experimenting with this, bring them into the fold and ensure that they are working according to the major program, incremental, and modular playbook. Hire talent into the corporation if it isn’t present.

Third, do serious modeling and simulation of sites and projected growth to establish the increments that make sense. Test those increments virtually with simulations. As Flyvbjerg says, this is a place to think slow and act fast. The time spent up front will speed deployment later and reduce overall program cost.

Fourth, seriously consider bringing engineering, procurement, and construction in house. Establish a strategy around those functions. Having a third party firm running a two decade program for you starts to look a bit odd after a while, and when it’s up and running, most of the design decisions will have been made, with only local approvals and inspections requiring variance. Firms will need the talent for oversight, control, and deployment, and whether it is inside or outside the firm is a choice.

Fifth, lock down the design of the increments. Establish clear change order policies for what can be approved and what can’t be approved by the people running the day to day deployments. Deployment will require local contractors who will be looking to maximize their revenue with change orders, and that can lead to both inflated costs but also lack of the standardization the solution requires.

As the program continues, there will be clear reasons to adjust the design of the increments, whether due to plummeting battery costs or soaring battery energy density changing the optimal mix, significant strategic changes in site scale or other reasons. Make changes to the design of the increments a significant governance decision. There is strong value in standardization, and changing is a serious choice that requires consideration and care.

Sixth, feet on the ground site surveys by the microgrid function are critical. Corporate data on sites is only so good, and corporate data systems weren’t created and filled with the needs of a charging microgrid in mind. The site surveys are about fitting the increments into the site and confirming which increment is appropriate, not changing the design of the increments.

Seventh, data is key to this. Establish a database of sites with the specifics of what the surveys find, the contractors that will be engaged, the status of submissions and approvals, the specific components to be deployed and the schedule. This isn’t a Microsoft Project GANTT chart, it’s a centralized, managed, and maintained database. At any given moment, it should be possible for the executives and staff in the corporate function to know exactly what microgrid components are at the site, and what is happening next.

Eighth, an executive dashboard of objectives and key results (OKRs) for the program is going to be required. The program needs to establish the OKRs, track them and report on them regularly, quite possibly at the board level given the expenditures involved and the level of transformation of the business being undertaken.

Ninth, weed out innovators when their useful time is over. The first phases of the program will require people who delight in building something new, figuring out the different optimal solutions, and deciding between them. But when the program shifts into deployment of the same incremental charging microgrids time after time after time, innovators will be unhappy. Find something else for them to do and bring in operational efficiency experts and people who love knowing exactly what to do. Both types of people are valuable, but the mix of them will change over the project, and if it’s not carefully attended to, something like the Tesla Supercharger mass firing can result, a disaster Barnard wrote about when it occurred. That was a failure of management, and it’s an obvious risk to avoid.

The key challenges related to charging microgrids identified in introductory articles for this strategy that this approach will address include the risk of lack of standardization, cybersecurity concerns, and the lack of site awareness and expertise.

Delivering high quality and reliable charging microgrids isn’t rocket science. Solar panels and batteries are inexpensive, commoditized, and reliable components. Charging is well understood and there are reliable, scalable solutions there. But not treating the program seriously and as a megaproject will result in a variety of predictable and expensive failures. Think slow and act fast.

Previous articles in this series:

About the authors:

Rish Ghatikar has an extensive background in decarbonization, specializing in electric vehicles (EVs), grid integration, and demand response (DR) technologies. At General Motors (GM), he advanced transportation electrification energy services, as part of a broader climate strategy. Previously, at Electric Power Research Institute (EPRI), he focused on digitalizing the electric sector, while at Greenlots, he commercialized EV-grid and energy storage solutions. His work at the DOE’s Lawrence Berkeley National Laboratory spearheaded DR automation to support dynamic utility pricing policies. An active climate advocate, Ghatikar advises on policies and technologies that align the grid with transportation and energy use for sustainable growth.

Michael Barnard, a climate futurist and chief strategist at The Future Is Electric (TFIE), advises executives, boards, and investors on long-term decarbonization strategies, projecting scenarios 40 to 80 years into the future. His work spans industries from transportation and agriculture to heavy industry, advocating for total electrification and renewable energy expansion. Barnard, also a co-founder of Trace Intercept and an Advisory Board member for electric aviation startup FLIMAX, contributes regularly to climate discourse as a writer and host of the Redefining Energy – Tech podcast. His perspectives emphasize practical solutions rooted in physics, economics, and human behavior, aiming to accelerate the transition to a sustainable future.

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy