Parker Australia’s electrification solutions improve operational efficiency while also reducing carbon emissions.

Parker Australia’s SMART electrification technology is helping mining companies grab the energy transition with both hands, with electric-powered systems capable of cutting carbon emissions, improving efficiencies and slashing operational costs.

Scott Addison and Andrew Rowley from Parker’s electrification team spoke to Australian Mining about how the company’s approach to electrification is revolutionising the sector.

“Parker’s SMART electrification revolves around three core pillars: integrated, connected and efficient systems,” Addison said.

“These pillars guide Parker’s product design and implementation of electrification solutions for various mining applications, from vehicles to drill rigs.”

Addison said the efficiencies and power density of Parker’s GVM PMAC liquid cooled motors are what truly sets the company’s solutions apart from traditional internal combustion engines.

“When you compare the efficiencies of our liquid-cooled Parker GVM motors, which typically operate at 94–96 per cent efficiency, and digital inverters, which are about 98 per cent efficient, it becomes clear why these systems are superior,” he said.

“In contrast, internal combustion engines typically experience losses ranging from 20 per cent to 30 per cent, making them highly inefficient in conjunction with the continued diesel and ongoing maintenance costs.”

The key to maximising the benefits of mining electrification lies in optimising the entire system.

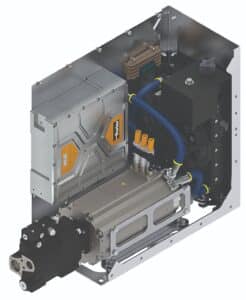

Parker’s designs integrate multiple layers of technology for electric power takeoff (ePTO) and traction applications, including hydraulic motion control, GVM PMAC electric motors and GVI inverters for motor control, which are all managed through Parker’s IQAN digital control platform.

This holistic approach ensures that every component of the system works seamlessly together, creating a more efficient, reliable and sustainable solution for mining operations.

A primary driver behind the adoption of Parker’s SMART electrification technology is the pressing need to reduce emissions.

But, like any nascent industry, electrification has faced its challenges.

“The rapid advancement of electrification technology has outpaced the Australian labour market’s ability to keep up,” Addison said. “Many companies and service providers lack the necessary skill sets to work with these advanced systems.”

The skills gap is a hurdle for the sector, as tradespeople and engineers need specialised knowledge to work on electrified equipment.

While technical institutes such as TAFE are starting to offer courses on electrification, there remains a gap in licensing and formal training, particularly at the university level.

Addison expressed concern that the mining industry is “playing catch-up” when it comes to understanding and implementing this cutting-edge technology.

Despite these challenges, Parker Australia has positioned itself ahead of the curve, acting as both a solutions provider and a consultant to mining companies about the future of electrification.

Addison explained that Parker’s team brings a wealth of real-world application knowledge, working closely with clients to guide them through the adoption of electrification.

“We’re very much seen as a consultant, but also as an engineering partner as well,” Addison said.

“We help clients define specifications, conduct engineering calculations, and model outcomes to ensure a smooth and successful transition, providing customers with the confidence to move forward with Parker electrification solutions.”

Parker’s approach is highly collaborative, and the company encourages clients to provide essential data, such as duty cycles of operation, to ensure the electrification solution is perfectly tailored to their needs.

“We engage with customers to make sure they understand how the system functions and how they can achieve the highest levels of performance and efficiencies for their machines,” Addison said.

This partnership extends to providing training and resources, ensuring companies are well-equipped to maintain and operate their electrified systems.

While the initial capital expenditure for electrification technology may be higher than traditional diesel-powered systems, Rowley said there were many long-term benefits.

“Your ongoing maintenance costs are significantly lower with electrified systems, and companies eliminate the need for fuel, oils and other consumables, leading to significant savings over time,” Rowley said.

“Although the payback period may be longer – typically around three to five years – companies see substantial cost reductions in the long term.”

Beyond cost savings, the sustainability benefits of Parker’s smart electrification solutions are clear.

“With our solutions, operators can achieve zero emissions in underground applications, and by eliminating diesel usage, operators can mitigate noise pollution and diesel particulate emissions,” Rowley said.

“This improves the operating environment of a underground mine and helps miners meet stringent regulatory requirements.”

Despite the clear advantages, some companies remain hesitant to embrace electrification, citing cost concerns and uncertainty about the technology.

But Addison and Rowley are seeing the industry come around.

“The next generation of engineers are driving new conversations about our energy future,” Addison said.

“These engineers, trained in mechatronics and electrical engineering, are questioning the status quo and pushing for more efficient, sustainable solutions.”

Parker is committed to helping companies overcome their hesitations by providing real-world examples and proven case studies.

“We show them what we’ve done with similar applications, and it gives them the confidence to move forward,” Addison said.

“With more companies seeing the long-term benefits of electrification, we expect the industry to continue shifting towards cleaner, more efficient technologies.”

As the mining sector grapples with the need to reduce emissions and improve efficiency, Parker Australia’s SMART electrification technology offers a clear path forward.

By focusing on integrated, connected, and efficient systems, Parker is helping mining companies transition to electric-powered operations that are not only more sustainable but also more cost-effective in the long run.

This feature appeared in the December 2024 issue of Australian Mining.