Australia’s mining industry, central to the nation’s economy, is under increasing pressure to decarbonise operations and meet stringent environmental standards. In line with this global shift towards sustainability and reducing carbon footprints, Alta Technology, a pioneer in battery and electrification technologies, told IM that it has introduced the PureTraction™ suite – a modular electrification system designed specifically for mining haul trucks.

Roy Zou, Managing Director of Alta Technology, says the suite offers both retrofitting solutions and original equipment options, providing a flexible approach to decarbonising mining fleets in a cost and time effective way. He points out that according to data from the Australian Government’s Department of Industry, Science, Energy, and Resources, the mining sector (including oil and gas extraction) contributes around 10-11% of Australia’s total greenhouse gas emissions annually. Particularly through the extensive use of diesel-powered haul trucks, which transport ore and other materials. As mining companies work to meet net-zero emissions targets by 2050, decarbonising these fleets has become a focal point of their sustainability efforts.

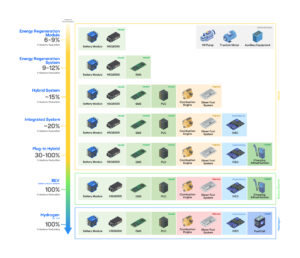

The Alta Technology PureTraction™ scope of supply

“Traditional approaches to decarbonisation have included fleet replacement, which comes at a significant financial and operational cost. PureTraction™ is a timely innovation that offers a cost-effective, scalable solution through retrofitting – modifying existing equipment with electrification and hybrid technologies. This approach minimises downtime, lowers capital expenditure, and allows mining operations to continue with minimal disruption, all while substantially reducing carbon emissions.”

The core of Alta’s offering is its PureTraction™ Electrification Suite, a modular system that integrates advanced battery and power management technologies to retrofit existing mining trucks. It offers three primary solutions – hybrid retrofits, full electric retrofits, and hydrogen fuel cell options. And crucially, Alta is unique in the market in already having real mining truck experience with all three. Alta Technology says it is also the first Australian company to offer a modular solution and is working to deliver the first hybrid truck to a mine in Australia.

Hybrid retrofits capture energy during braking and other operational activities, converting it into usable power that can then be fed back into the vehicle. This results in an immediate reduction in both fuel consumption and emissions. In real-world applications, such systems have demonstrated up to 15% reduction in emissions and fuel use. For companies seeking to make a quick impact on their sustainability metrics, this solution offers an effective starting point. In a hybrid collaboration with NHL, Alta replaced the traditional engine of the NTE260 with a smaller model, creating room for a 326 kWh battery system. This setup achieved an 8% reduction in fuel consumption during initial trials, with further testing expected to reach up to a 20% cut in emissions.

Full electrification is another key component of the PureTraction™ suite. In this model, diesel engines are replaced entirely by battery-powered systems. These vehicles are charged via external infrastructure, allowing for a fully decarbonised operation. The complete elimination of fossil fuel dependence in this setup makes it an attractive option for mining companies committed to achieving net-zero emissions. While the initial investment may be higher, the long-term benefits in terms of fuel savings, maintenance costs, and environmental compliance are substantial. The TR100 retrofit has already been supplied by Alta Technology – this eliminated the diesel engine, replacing it with a lithium battery system powered solely by electricity. This conversion delivered zero emissions and provides a pathway to 100% fuel reduction for heavy-duty trucks, supporting NHL’s shift to offering an all-electric fleet.

Hydrogen-powered solutions are the third option within the PureTraction™ suite. While still in the trial phase, hydrogen fuel cells hold immense potential for the future of clean energy in mining. Alta is actively testing hydrogen systems to ensure they meet the demanding requirements of heavy-duty mining operations. As these technologies mature, they could provide another pathway to zero-emission mining operations. Alta’s hydrogen-powered NTH150 working with NHL features 17 fuel cells, each with a 90 kWh capacity, to achieve substantial emission cuts. Currently in testing, this model highlights the potential of hydrogen as a clean fuel source for large-capacity mining vehicles.

A critical component of each PureTraction™ solution is Alta’s proprietary HSG8000 Total Power Control Unit (TPCU). This power control unit enables precise control over energy distribution and optimises the use of power within the system. Tested in global markets, including the Aurizon Battery Electric Tender, the TPCU provides up to 99% efficiency, significantly reducing energy waste and enhancing operational performance.

Zou told IM: “The TPCU and modular nature of PureTraction offer mining companies a flexible, high-efficiency solution with a compelling payback period of just three years. How is this possible? Retrofitting cuts carbon emissions by up to 100% when fully electrified, with lower cost and disruption than replacing entire fleets. Hybrid systems can cut fuel consumption by up to 20%, all while extending the life of existing equipment. A practical pathway to sustainability While government regulations and environmental policies drive much of the demand for cleaner technologies, mining companies are also recognising the financial and operational benefits of adopting such solutions.”

One of the key advantages of the PureTraction™ suite is its retrofitting capability. Rather than decommissioning existing fleets and investing in entirely new equipment, mining companies can upgrade their current haul trucks during routine maintenance periods. This makes retrofitting a practical and attractive option for mining operations that cannot afford significant downtime or capital expenditure. Retrofitting also extends the lifespan of existing equipment, reducing the need for costly fleet replacements. This solution aligns with both commercial objectives and sustainability goals, providing a more sustainable way for mining companies to continue operating within environmental regulations.

By integrating technologies like regenerative braking, retrofitted trucks can reduce operational costs, improve energy efficiency, and significantly reduce their carbon footprint. Alta Technology as an example has completed a regenerative braking project with a mining end user – China Shenhua – again highlighting its real customer experience.

Zou concludes: “By partnering with Alta Technology, mining operators can take a significant step towards meeting their sustainability goals without the burden of major fleet overhauls. As Australia’s first modular electrification suite, PureTraction™ sets a precedent for innovation in the mining sector, underscoring the critical role technology will play in transforming industries towards a cleaner future.”