Ampcontrol is powering the resources industry’s electrification revolution.

Ampcontrol is one company leading the mining industry’s push towards decarbonisation, leveraging its long history in electrical engineering to innovate solutions needed for this generational shift.

The company provides solutions in surface and underground mining environments, spanning electrical engineering services, power infrastructure, cabling and renewable energy solutions.

Ampcontrol principal engineer – mining and power Jason Padgett discussed how the company is driving this change, with innovations such as its DRIFTEX battery-powered electric vehicle (EV), which is already seeing strong uptake in the Australian resources sector.

The company’s journey towards mining electrification began with a clear focus on addressing customer needs.

“We spoke with our customers early on in the journey to look at what their challenges were in mine electrification and what we could do to help them on their decarbonisation journey,” Padgett told Australian Mining.

Collaborating and working with customers and industry is a part of Ampcontrol’s DNA and core to the company’s approach in developing innovative solutions.

Customer feedback saw Ampcontrol confront the challenge of battery use in hazardous environments – a section of the mining industry where decarbonisation challenges were particularly pronounced.

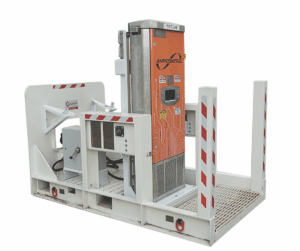

This saw Ampcontrol develop DRIFTEX, a battery-powered vehicle specifically designed for use in hazardous underground environments. The EV incorporates what Ampcontrol said is the world’s first IECEx-certified traction battery, making it safe to operate in Group 1 underground hazardous areas.

DRIFTEX not only offers enhanced safety but is also designed to improve the working environment for miners, removing diesel particulates and noise from the atmosphere.

“With DRIFTEX, operators no longer need hearing protection and can have conversations without the drone of a diesel engine or the smell of diesel fumes,” Padgett said.

DRIFTEX also delivers especially strong performance.

“Field trials showed that DRIFTEX is about 33 per cent faster than its diesel counterpart,” Padgett said.

“This is partly because of the vehicle’s electric drivetrain, which doesn’t have the torque curve of a diesel engine, meaning it accelerates straight away. This enables DRIFTEX to get instant speed when driving up a hill.”

Complementing DRIFTEX is Ampcontrol’s advanced charging infrastructure, which provides a reliable foundation for charging of EVs and equipment on mine sites, whether on the surface or underground.

Ampcontrol offers a range of charging options, including a 75-kilowatt underground charger and a surface charger capable of fully charging the DRIFTEX in just 10 minutes. This is in addition to Ampcontrol’s newly released megawatt charger, which has fast and dual-charge capabilities.

In innovating its charging stations, Ampcontrol recognised the need to deliver infrastructure that could achieve the same runtime as a tank of diesel.

Image: Ampcontrol

“With the battery chemistry we’ve used and the amount of work we’ve done in the cooling system, operators can fully charge their DRIFTEX in the same time it takes to refuel, top up the water and change over a diesel vehicle between shifts,” Padgett said.

Ampcontrol is also deeply involved in upgrading and managing the electrical networks that power mining operations.

“Whilst we innovate new solutions such as charging infrastructure and battery technology, Ampcontrol has over half a century of experience in engineering complex electrical solutions,” Padgett said.

This includes reviewing power infrastructure needs and possibilities for mines, integrating renewable energy assets and battery storage into operations, further reducing carbon emissions and enhancing the energy efficiency of mine sites.

Ampcontrol has a diverse team includes power engineers, transformer specialists, automation experts and software developers who collaborate to solve complex mining challenges.

“We manufacture the electrification solutions that we design, but we also spend a large part of our time at site post-implementation, supporting our customers with our 24–7 service offering,” Padgett said.

“We’re always asking our customers, ‘What are your issues and how can we help you solve them?’. We thrive on the challenge of defining a custom solution for them.”

Padgett said the breadth of the Ampcontrol team means many of the projects the engineers undertake are multi-disciplined.

“For DRIFTEX, there were a lot of different aspects to consider,” he said. “Not one engineer would be able to handle it all, so we work with our customers and industry partners, coming together as a team to propose the ultimate solution.

“This happens across all our R&D (research and development) products. It also means that we’re able to provide our customers with a premium service across a range of disciplines.”

Ampcontrol is always committed to finding new ways to innovate and help the mining industry to decarbonise.

This strategic focus is not just about staying ahead of the curve; it’s also about shaping the future of the broader mining industry.

By combining its deep expertise in electrical engineering with a commitment to innovation and customer-driven solutions, Ampcontrol is helping to drive the industry towards a more sustainable, efficient and safer future.

This feature appeared in the October 2024 issue of Australian Mining.