Orica Digital Solutions recently launched the next generation of its much-loved SHOTPlus solution.

In celebrating its 150th anniversary, Orica has had the opportunity to reflect on some of its most successful innovations.

In 2019, Orica’s ongoing digital expansion led to the creation of a dedicated digital solutions division, which sought to better connect the mining value chain.

Orica Digital Solutions is underpinned by four product categories: orebody intelligence, blast design and execution, geosolutions, and mine simulation and optimisation.

This dedicated digital arm has delivered many well-known solutions. This includes RHINO, Axis Mining Technology and WIREBmr for greater orebody intelligence, OREPro, BlastIQ and FRAGTrack for blast design and execution, GroundProbe, Syscom, 3VGeomatics and Navstar for downstream geotechnical and structural monitoring, and the Integrated Extraction Simulator for better decision-making across the mine-to-mill landscape.

But few Orica solutions have been as influential as SHOTPlus.

Featuring charging and initiation design tools, superior visualisation and blast analysis functionality, SHOTPlus supports regulatory compliance, drives higher productivity, and reduces the overall cost of a drill and blast operation.

SHOTPlus is a foundational Orica technology, meaning not only has it inspired the research and development (R&D) of other Orica solutions, but it is also inherently compatible with the company’s broader product portfolio.

“SHOTPlus celebrates its 35th anniversary this year, so it’s a bit of a mainstay in the market,” Orica senior product manager – technology Daniel Andrew told Australian Mining.

“It’s used to enable other solutions within Orica, including the i-kon electronic blasting system, our wireless blasting technology WebGen, as well as our bulk explosives range. SHOTPlus is used with those technologies to design blasts.

“But SHOTPlus is also used to enable more recent developments such as BlastIQ, OREPro, and BlastVision.”

While SHOTPlus’ initial ingredients remain central to the product’s current iteration, the solution has continued to evolve, which has been driven just as much by Orica’s own R&D as it has been by customer appetite.

“Instead of just maintaining its initial use case, which was initiation design, SHOTPlus has continued to develop and evolve as our customers needed it to,” Andrew said.

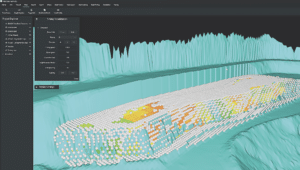

“It was originally a two-dimensional tool that demonstrated how an initiation design would be implemented in the field. Then it evolved into a three-dimensional application.

“Then, as there was demand for blasting technologies or techniques, such as through-seam blasting, SHOTPlus developed in a way that enabled not only engineers to design those blasts, which are incredibly technical, but also enabled users to implement those blasts out in the field.”

Image: Orica

Orica Digital Solutions senior manager for technology Matthew Craft echoed Andrew’s sentiment.

“SHOTPlus has really struck the balance between managing complex situations like through-seam blasting as intuitively as possible,” Craft told Australian Mining.

“There’s a real coming-of-age when an Orica employee becomes a SHOTPlus expert, because it’s such a universally loved solution internally and externally.

“The challenge Dan and his team have now is maintaining the essence of a loved product such as SHOTPlus while continuing its evolution through new generations.”

As of 2024, SHOTPlus has more than 2000 users worldwide, many of which are now benefiting from the release of Next Gen SHOTPlus.

In its latest iteration, SHOTPlus will continue to be the focal point of drill and blast decision-making while supporting Orica’s heightened focus on facilitating adjacent and integrated workflows.

Next Gen SHOTPlus, Andrew said, will support cloud-based collaboration for a single source of truth.

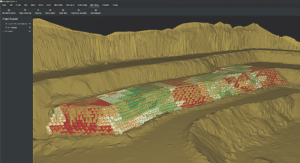

“Drill and blast doesn’t operate in a vacuum; it is part of a wider mining value chain,” he said. “So Next Gen SHOTPlus will be integrated with a cloud-based source of truth in the form of a model through time.

“This will be a four-dimensional digital replica of an operation, which can store geo-metallurgical and topographical information that represents the in-situ and blasted rock mass, as well as other relevant reference data, such as drone flyovers.

“Next Gen SHOTPlus will also be the storage centre for blasts and all their relevant information as they change through time.

“Users will no longer be working with files shared over OneDrive, for example. Rather, you can think of Next Gen SHOTPlus as the Google Earth of a mining operation. A user can visualise their blasts, and choose which blast to work with, or the area they want to work with.”

Andrew said Next Gen SHOTPlus also enables users to visualise and manage big data in a performant manner.

Image: Orica

“As we were developing this new product, we did a lot of collaboration and workshopping with our customers, including SHOTPlus users and customers who use competitor products,” Andrew said.

“While blast design has historically been thought as more of an art than a science, where data is not a central focus, customers are coming to realise the power of data in blast design.

“A mining operation has large data sets, whether it be topographies, high-detail photogrammetry or geo-metallurgical block models, which can be used to a blast engineer’s advantage.

“And we believe the platform we’re building is far and away the most performant in the market when it comes to using big data.”

Next Gen SHOTPlus also enables users to model outcomes before they are implemented, with engineers able to run calculations and simulations before a blast occurs.

With solutions such as Next Gen SHOTPlus, Craft believes Orica is inspiring a new paradigm in drill and blast.

“Next Gen SHOTPlus will lay the foundations for more and more innovation, not only within our blast design and execution space, but also within other areas such as ground radar and orebody intelligent data management,” Craft said.

“Being able to powerfully handle big data at high volume with predictive capability is a massive step change for the industry. This is something we’ve been trying to achieve for a while.”

This feature appeared in the October 2024 issue of Australian Mining.