Steel industry leader ArcelorMittal recently commissioned a new, two-stand ladle furnace at its Fos-sur-Mer site in southern France. The Luxembourg-headquartered group stated that the furnace will cut carbon emissions from the flats producer by up to 10%.

In an October 3 announcement, ArcelorMittal stated that each of the two stands on the new equipment can hold more than 330 metric tonnes of crude steel and will boost production by 10% as early as 2025.

The group noted that work to build the new equipment started in Q1, whilst testing occurred over France’s summer.

Fos-sur-Mer is a Significant Contributor to the EU Steel Industry

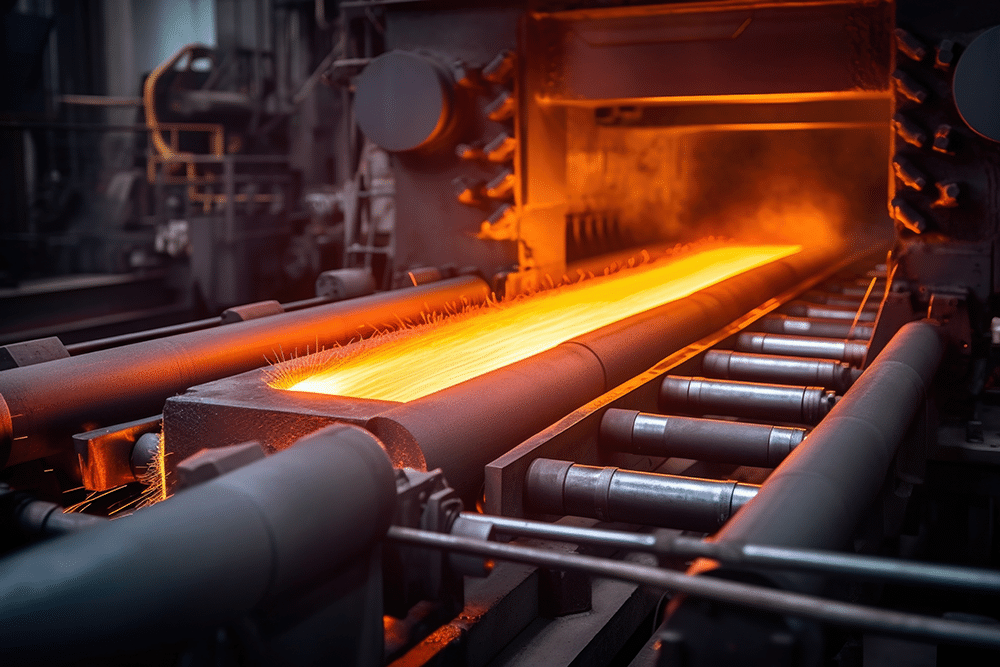

Ladle furnaces are used in secondary steelmaking to refine steel to desired grades and properties. This is accomplished by reheating the steel and adding alloying elements before casting and rolling.

ArcelorMittal stated that the new equipment carries a €76 million ($83.4 million) price tag, of which the French government donated €15 million ($16.4 million).

ArcelorMittal originally announced its plans to install the new ladle furnace at Fos-sur-Mer, which is in the town of the same name and about 50 kilometers northwest of Marseille, in August 2023.

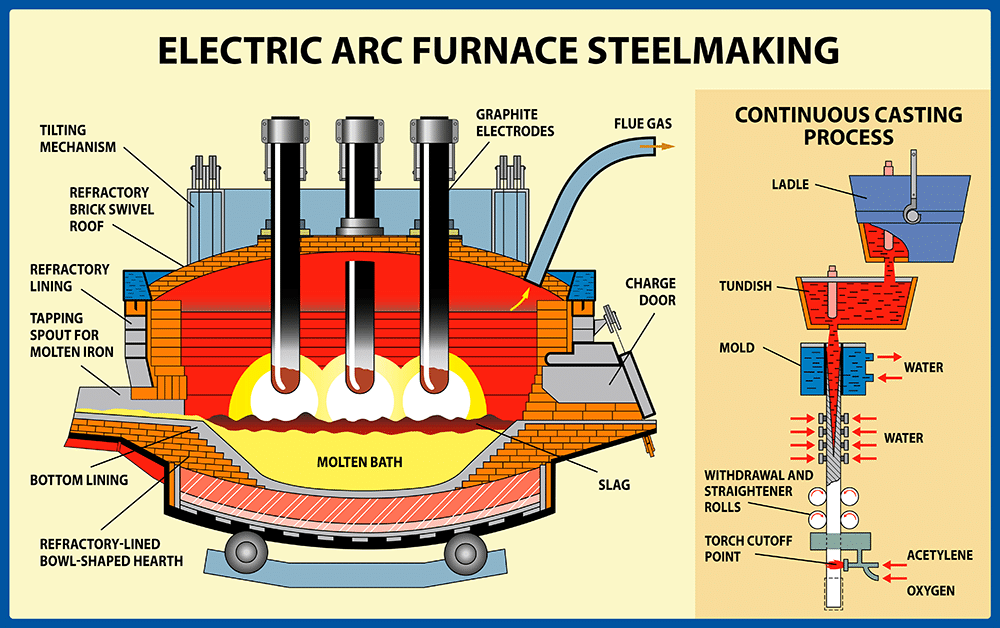

At that time, the European steel industry giant also announced its plans to install a new electric arc furnace at the site by 2030.

Fos-sur-Mer has two blast furnaces, each with a heath diameter of 11.8 meters, that can produce a combined 7,000 metric tons of pig iron per day.

The plant has an estimated nominal capacity of 60 million metric tons per year of crude steel via two 335-metric ton basic oxygen furnaces, which it casts into slab for rolling into hot rolled coil.

Get all of the latest steel price trends from MetalMiner’s free Monthly Index report. This document contains monthly price-indexes for the steel industry and 9 other metal markets.

The Latest in an Array of Changes

Fos-sur-Mer also temporarily idled its BF 2 in Q4 2022, citing poor steel market conditions. Emissions concerns also prompted a temporary shutdown of the entire plant in mid-2023, while the plant’s BF No. 1 went off stream in Q4 of that year for maintenance works.

Electric arc furnaces are easier to operate for steelmakers as they use electricity to melt steel, whilst blast furnaces must operate continuously in multi-year campaigns to maintain the proper conditions to reduce iron ore into pig iron

Moreover, shutting down a blast furnace can result in molten iron in it to cool down and the refractory lining to crack.

Get valuable steel market trends, price alerts, and other commodity news, supporting your business in mitigating the impact market fluctuations. Register for MetalMiner’s free weekly newsletter.