Hitachi and Wenco are attracting plenty of attention for their new stockpile management solution.

Stockpiles are one of the few aspects of mining operations that remain unmanaged by material-tracking technology, leading to inefficiencies that impact plant operations and productivity.

Old-school methods of treating stockpiles as uniform blends have led to plant feeds being inconsistent, undermining the ability to achieve shift plan targets.

Wenco International Mining Systems has built a new product set to address these longstanding issues, bringing a new level of precision and control to the management of stockpiles.

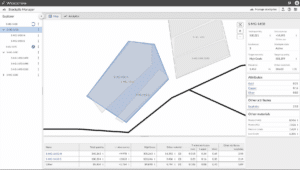

Wenco’s Stockpile Manager is an innovative system that fundamentally changes the way run-of-mine (ROM) stockpiles are perceived and managed.

Rather than viewing stockpiles as standardised masses, Stockpile Manager captures detailed location data for each load, enabling a more granular understanding of material attributes.

This approach is similar to how shovels and excavators utilise dig blocks but extends that precision to stockpiles.

“About two years ago, several of our customers in different regions were actively asking Wenco if we had a product that could deliver a higher fidelity model of their stockpiles,” Wenco product line manager of fleet management Reid Given told Australian Mining.

“They explained to us some of the challenges such as high variability across the stockpile, and the impacts of those challenges, including mills calling for an increased grade.

“The only knowledge they had as to what was in the stockpile were values based on averages.”

Recognising this gap in the market, Wenco decided to develop Stockpile Manager as a standalone product.

The solution was built using Wenco’s advanced architecture, designed to be agnostic to fleet management systems.

“The product is built as a standalone product, and can be made to interface with a variety of systems, including those leveraged underground where stockpiling at the surface occurs,” Given said.

Image: Hitachi

The product is GPS agnostic and therefore can work with the low-precision GPS receivers commonly used in haul trucks.

“We didn’t want to build a product that required the bulk of our customer base to undergo extensive hardware upgrades,” Given said. “Higher precision GPS will yield a more accurate model, but low precision GPS will still result in value for ore controllers.”

Stockpile Manager was officially launched at MINExpo in September, with a presentation on stage at the Hitachi theatre.

The product’s launch was highly anticipated by the industry, with early feedback from beta customers and industry professionals being overwhelmingly positive.

“We’ve heard ‘Can I have this product now?’ multiple times,” Given said. “That’s very exciting to hear.”

Hitachi Construction Machinery Australia national manager of mining technology Paul Green said Stockpile Manager will solve pressing pinch points in the mining industry.

“Innovations like Stockpile Manager are crucial for the industry, as they provide the precision and control needed to enhance stockpile management and ensure more consistent and effective plant operations,” he told Australian Mining.

As the mining industry continues to face increasing pressures to optimise operations and reduce costs, products like Stockpile Manager will become increasingly valuable.

Being able to provide a more precise and comprehensive understanding of stockpiles, Wenco’s new system enables mining companies to better utilise their resources and improve the consistency of their operations.

This feature appeared in the October 2024 issue of Australian Mining.