A company dedicated to optimising the safety and performance of industrial plant installations and maintenance is upgrading the safety of bucketwheel reclaimer head fastening with a Technofast hydraulic bolting solution available throughout North America.

Motion Australia – a wholly-owned subsidiary of Genuine Parts Company – uses Technofast EziTite® hydraulic bolts to precisely and swiftly secure iron ore reclaimer drive heads in Australia, doing the job multiple times faster than alternative methods – often four or five times more swiftly with less handling and more safety, according to the company.

The same range of products are applicable for reclaimer applications globally, according to Technofast founder and CEO, John Bucknell.

Technofast products are distributed throughout North America, with permanent and long-established representation in the region.

Motion Australia’s Engineering Services Manager, WA, Harrison Hart, said: “While eliminating high labour inputs, the big benefit of this technology that matters most to miners is the safeguards the EziTite fasteners offer against OH&S hazards. These include hand and fatigue-related hazards occurring with slower and less precise fastening methods.

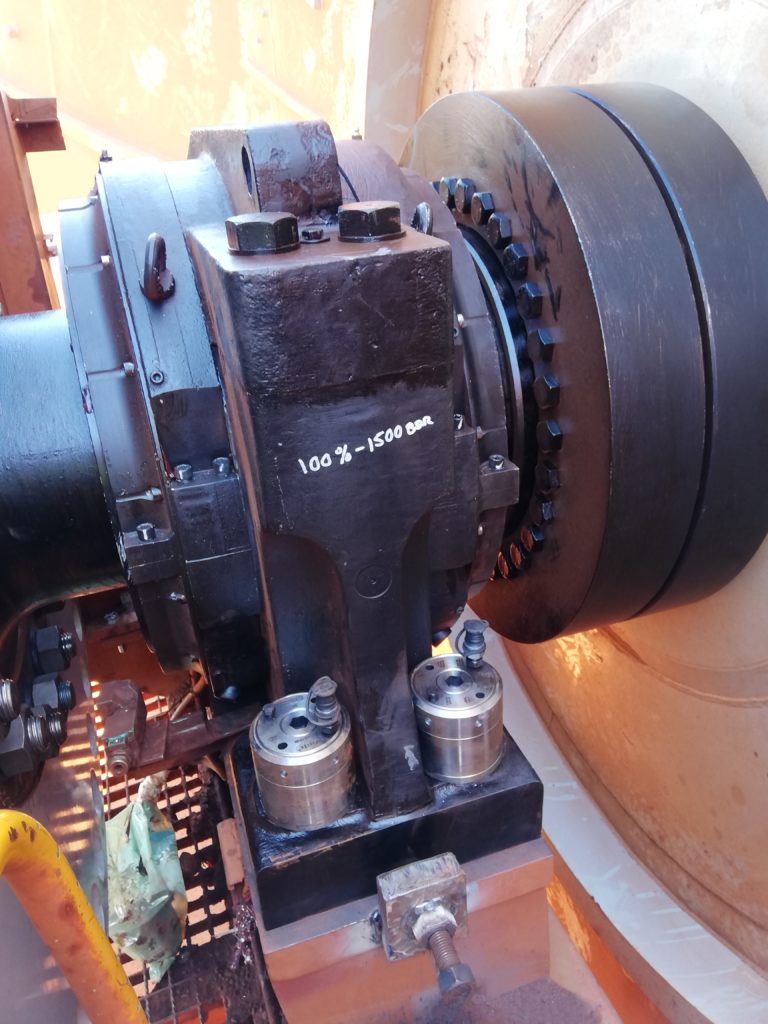

“Because of their safety, speed, and precision in operation, we have adopted the technology widely, using hundreds of EziTite M56 fasteners on bucketwheel reclaimer heads over the last couple of years. We have introduced them as an integral part of our broader service solutions that respond to the needs of big primary producing industries, such as mining, which are absolutely focused on safety.”

He added: “The hazard reduction and accuracy of these precision-engineered, high performance, hydraulically operated bolt tensioning devices is immediately apparent to miners and OHS personnel in multiple industries that operate bucketwheel reclaimers.”

EziTite bolts are screwed into place by hand, then stretched hydraulically with direct axial force to achieve precise and repeatable tension and clamping force on the joint. When this force is attained, they are then locked in place mechanically for as long as they are needed. The process is simply reversed for maintenance: by reapplying the hydraulic pressure, releasing the simple, secure mechanical lock ring and then relieving the input pressure, allowing removal by hand, again saving time and manual handling.

“Rather than using torque methods to secure a nut, they can be set up and operated four or maybe five times faster than alternative methods,” Hart says. “They achieve highly accurate and measurable consistency over multiple bolts or sets of bolts.”

This same precision is possible even when the EziTite bolts are daisy-chained to apply joint clamping force simultaneously, or, as in this application, actuated individually.

Hart added: “The Technofast hydraulic fastening method ensures precise uniformity of fastening and clamping as required by individual applications. We have found its accuracy well in excess of other methods. It easily provides huge forces needed for large diameter bolts with consistent and even bolt tension for joint integrity, to make the installation stronger, longer-lasting and more durable, thus adding another layer of safety.”

Speed a bonus to safety

“Speed is mostly a bonus in this application, but a highly worthwhile value-add nevertheless when you consider that bucket wheel reclaimers are often handling anything from 500-20,000 t/h. With ore and coal prices fluctuating this year between a $80 and $130 a tonne, greater uptime and throughput is definitely a consideration. Labour input cost is always much more expensive than an EziTite bolt is ever going to be. We save on maintenance time and put the machinery to work sooner, shifting ore and making money.”

Speed and ease of use are illustrated by the fact that it typically takes Motion Australia about a minute to apply accurate pressure to one bolt. The old system has a long setup time, with the result that the Technofast solution is, according to the company, four to five times faster.

Hart says: “As a strongly service-committed solutions provider, whose integrity and advice are highly respected by these on-site partners, we are very pleased with the quality and prompt supply by Technofast of this locally manufactured product. We appreciate also the excellent support from Technofast’s WA Manager, Watson McIlveen, who always gives realistic timeframes and reliable undertakings.

“But the biggest plus – and reason we have introduced EziTite as part of our holistic solutions – is safety. By reducing handling and eliminating rotational hazards from the bolting process in this application, the technology responds to customer expectations upon us, as a trusted advisor and solution provider, for safer and more accurate solutions.”

Technofast Founder and CEO, John Bucknell, says the experience of people such as Harrison Hart speaks volumes about the global standards of quality and backup provided by the Technofast family of technologies.

Bucknell says: “Technofast technologies are in demand because of quality, service backup – and because we are local, typically halving delivery times for technologies such as fasteners, tensioners, and lifting cylinders up to 1,000 tonnes, which are in high demand from companies seeking to protect themselves against supply chain disruption.

“Motion Australia (formerly CBC) is dedicated to improving component performance and increasing plant up-time with safety paramount. Maximising safety and productivity are central to everything they do, providing their globally connected customer base with world-class solutions. They have an outstanding national reputation, dealing only with top quality suppliers, which is a great compliment to us.”