Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

As major consumers of coal-based steel, U.S. and E.U. automakers can catalyze market for green steelmaking

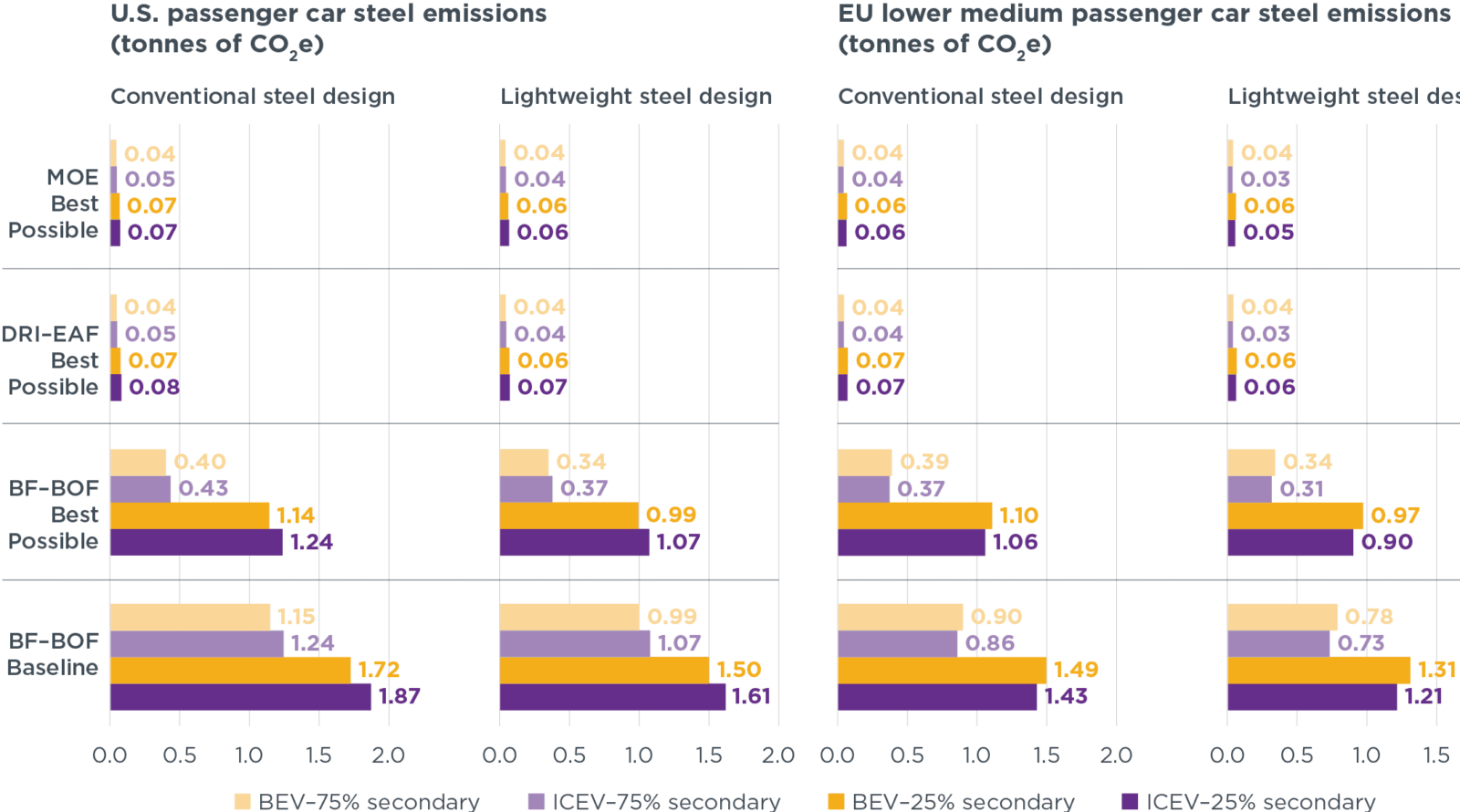

The auto industry can eliminate more than 95% of greenhouse gas emissions from producing the steel for passenger vehicles by switching to fossil fuel-free steel, according to a new report released today by the International Council on Clean Transportation (ICCT).

“Primary steel, a critical component of today’s auto sector supply chain, is a global driver of greenhouse gas emissions and a danger for the health of local communities, due to the industry’s heavy reliance on coal. Already, steelmakers are piloting fossil fuel-free technologies that can eliminate 95% of the emissions from producing steel in the average vehicle” said Anh Bui, a researcher at the ICCT. “As automakers invest in strategies to meet ambitious climate goals, prioritizing fossil-free steel would slash emissions and create a powerful market signal.”

The report, Technologies to reduce greenhouse gas emissions from automotive steel in the United States and the European Union, compares strategies for automakers to reduce steel-related emissions from vehicles.

Most of the greenhouse gas emissions from the lifetime of vehicles comes from the gasoline and diesel they burn. But vehicle manufacturing causes significant emissions too – and as we make progress in leading countries switch over to electric vehicles running on an increasingly decarbonized grid, those manufacturing emissions grow in importance. To achieve a fully net zero GHG transportation sector by 2050, it will be necessary to drastically reduce the embodied emissions in key materials like steel and batteries.

Procuring primary steel without fossil fuels is the strongest possible pathway to reduce steel-related emissions from vehicles – and this could be done at scale in the U.S. by the end of the decade. Collectively, automakers are among the largest buyers in the steel market in both the U.S. and EU. In 2022, the auto industry consumed 26% of the 82 million metric tons of steel produced in the U.S., and 60% of all domestic primary steel. In the same year, 17% of the 136 million metric tons of steel produced in Europe went to the auto industry, and 24% of all domestic primary steel. Due to the primary steel industry’s heavy reliance on coal, steel is responsible for up to 27% of embodied emissions in a typical internal combustion engine vehicle.

“Procuring primary steel made with green hydrogen and renewable electricity instead of fossil fuels takes a big chunk out of supply chain emissions — but it’s also very cost-effective for automakers,” said Marta Negri, an associate researcher at the ICCT. “For less than 1% of vehicle costs, automakers can help transition one of the dirtiest industries on the planet toward clean energy, provide clean air to local communities, and meet their climate goals.”

Publication details

Most of the greenhouse gas emissions from the lifetime of vehicles comes from burning gasoline and diesel. But vehicle manufacturing also generates significant emissions. As the world transitions to electric vehicles powered by an increasingly decarbonized grid, these manufacturing or embodied emissions grow in importance. To achieve a fully net zero GHG transportation sector by 2050, it will be necessary to drastically reduce the embodied emissions in key materials like steel and batteries.

Steel manufacturing is one of the most energy and emission intensive industries worldwide, relying heavily on fossil fuels, especially coal, in primary production. In vehicle manufacturing, steel is the most used material by mass, typically making up between 50% and 66% of the vehicle, depending on the model, segment, and powertrain type.

Given the automotive industry’s substantial steel consumption, automakers may be uniquely suited to drive demand for fossil fuel-free steel and influence the steel industry transition away from coal-based steel production.

This analysis examines the ability of automotive industries in the United States and the European Union to reduce GHG emissions of automotive steel through:

- Discussing current steel production pathways and associated GHG emissions

- Describing pathways to produce fossil fuel-free steel

- Exploring other modes to reduce steel demand in vehicles

- Comparing GHG emission reduction potential for internal combustion engine vehicles (ICEVs) and battery electric vehicles (BEVs) in the United States and the European Union

- Summarizing the other aspects necessary for the transition to green steel

The research arrives at the following key results:

- The auto industry can eliminate more than 95% of greenhouse gas emissions from producing steel for passenger vehicles by switching to fossil fuel-free steel. Doing so would reduce overall vehicle manufacturing emissions by up to 27%.

- Using fossil fuel-free steel in vehicle production increases cost by $100–$200, or less than 1% of the price of an average new vehicle

- Fossil fuel-free primary steel production technologies already exist, and production capacity can increase, but not without commitments from buyers.

Courtesy of the International Council on Clean Transportation (ICCT). Full report PDF download.

The International Council on Clean Transportation (ICCT) is an independent research organization providing first-rate, unbiased research and technical and scientific analysis to environmental regulators. Our mission is to improve the environmental performance and energy efficiency of road, marine, and air transportation, in order to benefit public health and mitigate climate change. Founded in 2001, we are a nonprofit organization working under grants and contracts from private foundations and public institutions.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica.TV Videos

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy