Following its acquisition of the Schenck Process mining-related business in November 2022, Sandvik has been working hard behind the scenes to bring its new offering and capabilities to market.

In October 2023, Sandvik reached a key milestone in the integration of Schenck Process Mining into its Rock Processing Solutions Business area when the company changed the names of the legal entities that came with the acquisition.

The newly acquired entities provide Sandvik Rock Processing with a stronger global reach, particularly in geographies where it previously had little presence.

This is especially true in Australia, where Sandvik Rock Processing only had a small team, while SP Mining had the majority of its engineering and research and development teams as well as production and service facilities in Australia.

Schenck Process Australia, which employed over 400 people, became Sandvik Rock Processing Australia, now a major hub for Sandvik’s global Screening Solutions Division.

Since the renaming of the legal entities, the integration of the SP Mining business has been a key focus area for the company.

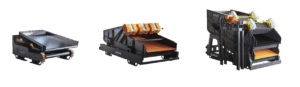

Part of this work includes the rebranding of all aspects of the business. In parallel, the SP Mining and Kwatani equipment offerings have been united under the Sandvik brand. The company said the result is an unparalleled range of vibrating screens, feeders, screening media and train loaders.

In early May, Sandvik achieved another key integration milestone, shipping out the first Sandvik-branded SP Mining screen from its Jandakot production facility in Western Australia.

“Apart from the change to the look, branding and Sandvik nomenclature, nothing else has changed,” Sandvik global head of marketing – screening solutions Peter Newfield said. “Our legendary reliability, technology and aftermarket support remains as our customers have come to expect.

“We are now better equipped than ever to help our customers to optimise their comminution and material handling operations for maximum performance, safety, and efficiency.”

Image: Sandvik

Newfield said combining the industry leading screening, feeding, and loading expertise of Schenck Process Mining and Kwatani with Sandvik’s mastery of crushing and wear protection allows the company to bring an unrivalled equipment line-up to market.

“This unique offering is underpinned by the expert process knowledge of our teams, a full range of digital tools, high quality OEM (original equipment manufacturer) spare parts, consumables, and life-cycle services,” he said.

But the integration wasn’t just limited to the equipment.

Newfield said that it has been a major project that involved every part of the business. In essence, the acquired Schenck Process entities had to become Sandvik Rock Processing entities and so SP Mining staff had to embrace the Sandvik culture and learn the company’s systems, and ways of working.

“Of course, a big part of the integration was making sure that our key stakeholders understood the benefits of us becoming a fully integrated part of Sandvik,” he said.

“It takes time for people to adjust to change, and they need to know what is happening throughout the process. We have worked hard to communicate the changes to all our key stakeholders including our customers and employees.”

The company has changed the branding of all its Australian facilities, motor vehicles, and the work clothes that its people wear on the job every day.

The Sandvik Rock Processing Solutions website and other marketing collateral have also changed to showcase its new product offerings and brand.

According to Newfield, these were the final steps in the integration process.

“Our new offering along with the advances that our combined R&D teams are making, allow us to partner with our customers to address our industry’s biggest challenge – making mineral processing more eco-efficient,” he said.